Electric vehicle in-wheel motor stator

A hub motor and electric vehicle technology, applied in the field of electric vehicles, can solve the problems of high temperature damage to internal electronic components, hinder the use and popularization of electric vehicles, and the short service life of the motor, so as to reduce the temperature rise of the iron core and improve the quality stability and product performance, the effect of improving slot utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

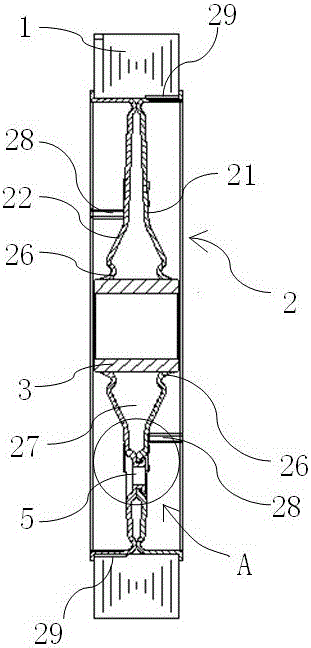

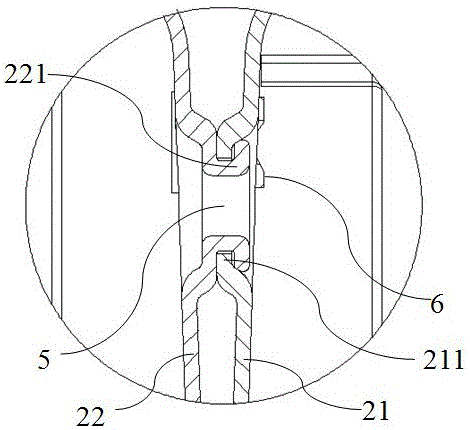

[0039] The stator of the electric wheel hub motor is fixed to the frame through the connecting shaft, and the stator forms a rotating connection structure with the rotor through the end covers on both sides of the shaft. The stator is not only affected by the electromagnetic field force, but also bears the impact force from the hub. , supporting the whole structure of the motor. The stator of the electric wheel hub motor includes an iron core 1 and a bracket 2 .

[0040] In this embodiment, the outer diameter of the stator 1 is 206.9 mm. By increasing the outer diameter of the stator, expanding the effective air gap flux, increasing the electromagnetic force and the magnetic force arm, the torque of the motor is increased, and at the same time, a reasonable inner diameter of the stator is designed to reduce The characteristic volume of the iron core improves the power density of the motor. Under the condition that the hub motor is applied to a 10-inch wheel hub, it maximizes t...

Embodiment 2

[0048] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the outer diameter of the stator 1 is 206.8mm, the number of slots in the stator core 1 is 54 slots, and the iron core 1 The tooth width is 5.3mm.

Embodiment 3

[0050] The technical solution in this embodiment is basically the same as the technical solution in embodiment 1, the difference is that in this embodiment, several self-riveting positioning holes 5 distributed in the circumferential direction are used as winding positioning holes 4 after being riveted, As a positioning reference when winding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Tooth width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com