Proton exchange membrane fuel cell hydrogen discharge system capable of being quickly started at low temperature

A proton exchange membrane and fuel cell technology, applied in the direction of fuel cell additives, fuel cell parts, etc., can solve the problems of complex structure design, high energy, etc., and achieve the effect of improving opening speed, simple operation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

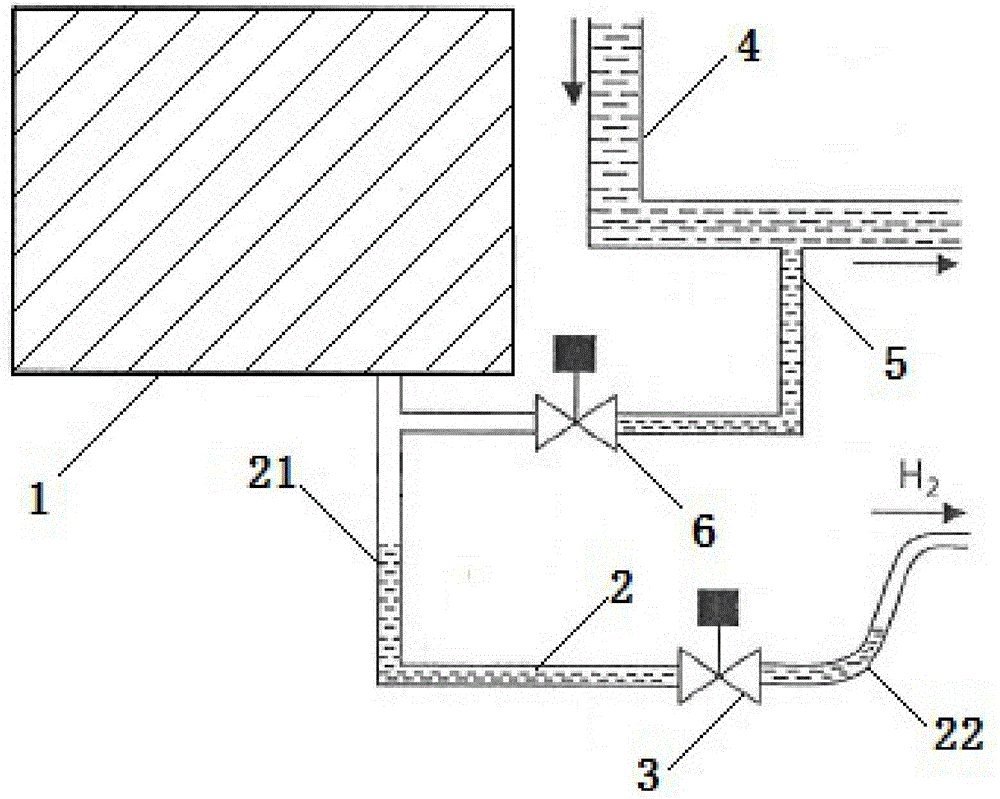

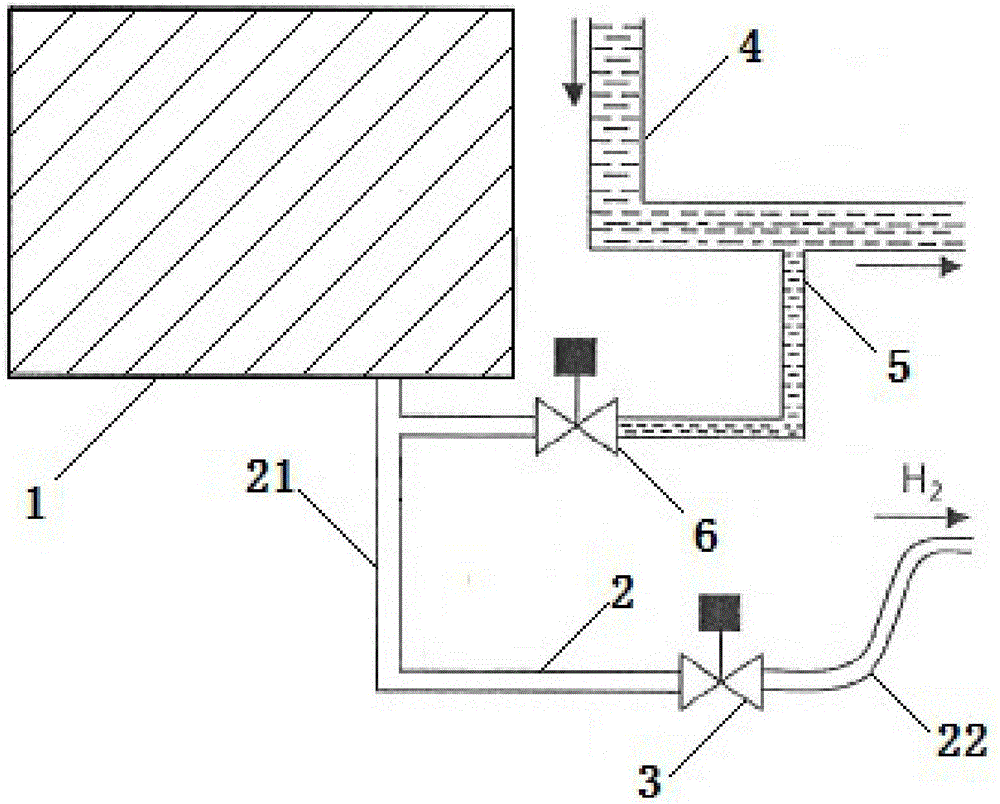

[0024] like figure 1 As shown, a proton exchange membrane fuel cell hydrogen exhaust system that can be quickly opened at low temperature includes: a hydrogen exhaust pipe 2, a hydrogen exhaust solenoid valve 3, a cooling liquid branch 5 and a liquid injection valve 6, and the hydrogen exhaust pipe 2 includes an inlet pipeline 21 and an outlet pipeline 22, both of which are connected through the hydrogen exhaust valve 3, and the inlet of the inlet pipeline 21 is connected to the fuel cell stack 1; the inlet of the hydrogen exhaust pipeline 2 The pipeline 21 is connected to the cooling liquid branch 5 through the liquid injection solenoid valve 6 , and the other end of the cooling liquid branch 5 is connected to the cooling liquid circuit 4 or the water tank. The position of the hydrogen exhaust valve 3 is lower than the inlet pipeline 21 and the outlet pipeline 22 .

[0025] The working principle of the present invention is like this:

[0026] In the hydrogen exhaust system,...

Embodiment 2

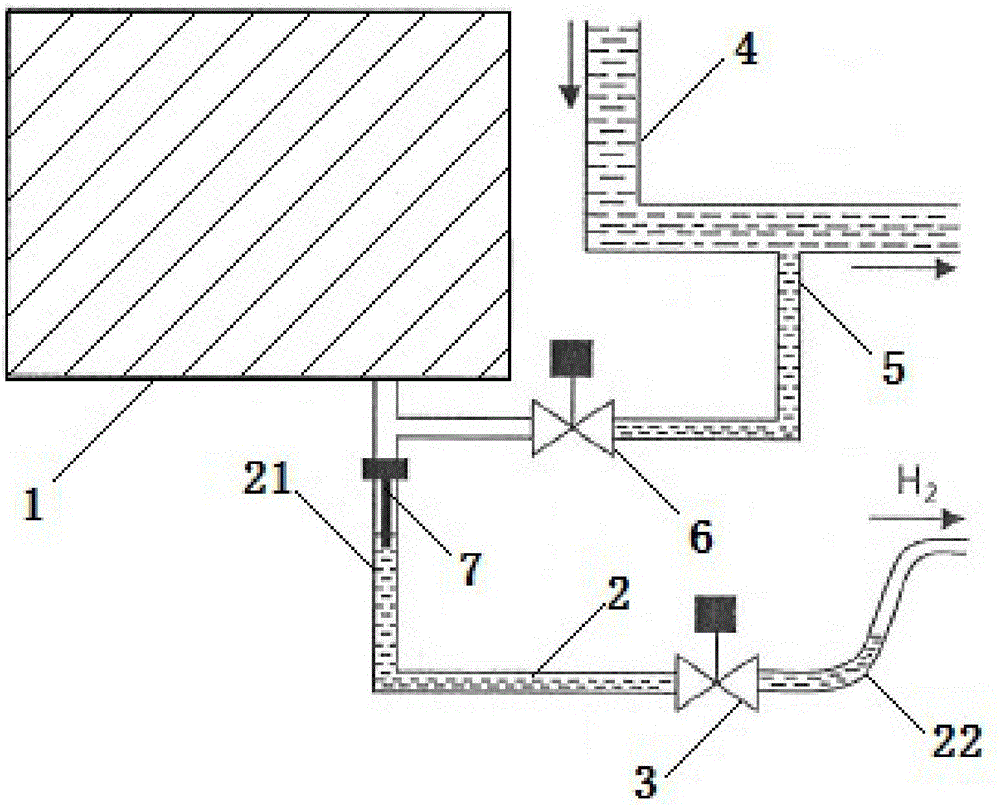

[0029] like image 3 As shown, the others are the same as in Embodiment 1, and a liquid level sensor 7 is also arranged in the inlet pipeline 21 .

[0030] In this embodiment, the cooling liquid filling process is controlled by the liquid level sensor 7 . The advantage of using a liquid level sensor for perfusion control is that the amount of coolant entering the hydrogen exhaust pipeline can be accurately controlled, avoiding poor antifreeze effects caused by fluctuations in the amount of perfusion liquid or pollution of the stack in extreme cases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com