Die casting die rapid design and management system and usage method thereof

A management system and die-casting mold technology, applied in manufacturing computing systems, data processing applications, special data processing applications, etc., can solve problems such as low management efficiency, molds cannot be recycled and reused, and weak flexibility, and achieve convenient management and monitoring. , The effect of facilitating product innovation and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

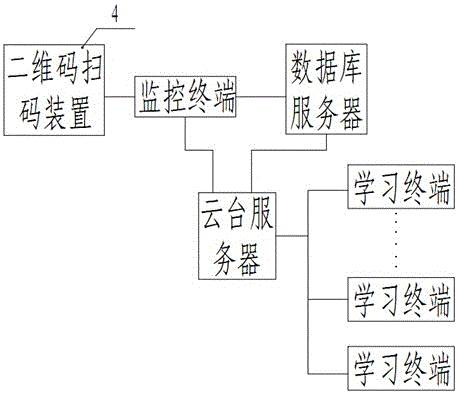

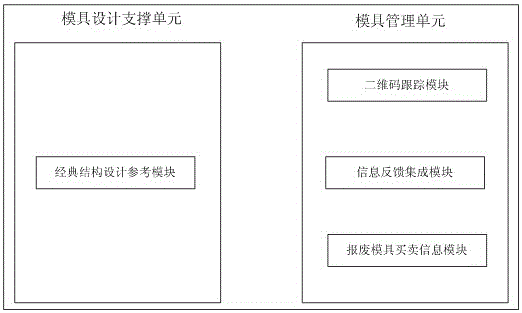

[0024] Embodiment 1: as Figure 1-Figure 5 As shown, a die-casting mold rapid design and management system includes a classic structure design reference module, a two-dimensional code tracking module and an information feedback integration module. The classic structure design reference module provides different mold design reference data, and the reference data adopts the existing The classic structural design data and reference data are stored in the database server. The two-dimensional code tracking module and the information feedback integration module record the production and maintenance status of the mold. The two-dimensional code tracking module includes the two-dimensional code label and multiple Two two-dimensional code scanning devices arranged at different stations, each two-dimensional code scanning device is respectively connected to the monitoring terminal, and the monitoring terminal is also connected to the database server.

[0025] Preferably, each of the abov...

Embodiment 2

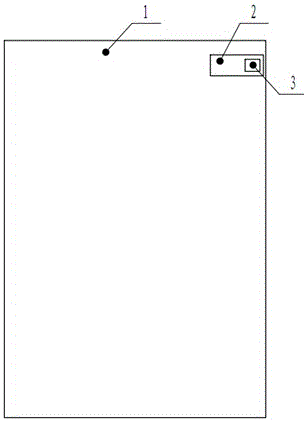

[0028] Embodiment 2: as Figure 1-Figure 5 As shown, a die-casting mold design and repair monitoring system includes a mold body 1 and a plurality of two-dimensional code scanning devices 4, a nameplate 2 is arranged on the mold body 1, a two-dimensional code label 3 is attached to the nameplate 2, and a plurality of two-dimensional code scanning devices 4 are arranged on the mold body 1. The two-dimensional code scanning device 4 is used to scan the two-dimensional code label 3, and is respectively installed at different stations and connected to the monitoring terminal, which is also connected to a database server for storing mold information.

[0029] Principle of use: The two-dimensional code scanning device of each station scans the two-dimensional code, and feeds back the scanned information of the station to the monitoring terminal, and the monitoring terminal calls the basic information of the mold at the station through the database server. The information includes mo...

Embodiment 3

[0030] Embodiment 3: as Figure 1-Figure 5 As shown, a method of using a die-casting mold rapid design and management system, the method includes the following:

[0031] Classic structure design reference module: stored in the database server in the form of pictures or 3D models, providing users with mold design reference data for different structural parts. The mold design reference data comes from senior mold designers in the industry. Users can carry out classic design Learning, you can also compare with your own design tasks, find out what is available, and solve the problems you encounter in the design process; add text descriptions to the classic structural design, and describe the design ideas and key difficulties;

[0032] Two-dimensional code tracking module and information feedback integration module: set a unique two-dimensional code label on the front mold base during mold design, and enter the two-dimensional code information into the database server, and the oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com