A method and system for predicting the center zone temperature of a blast furnace throat cross temperature measuring device

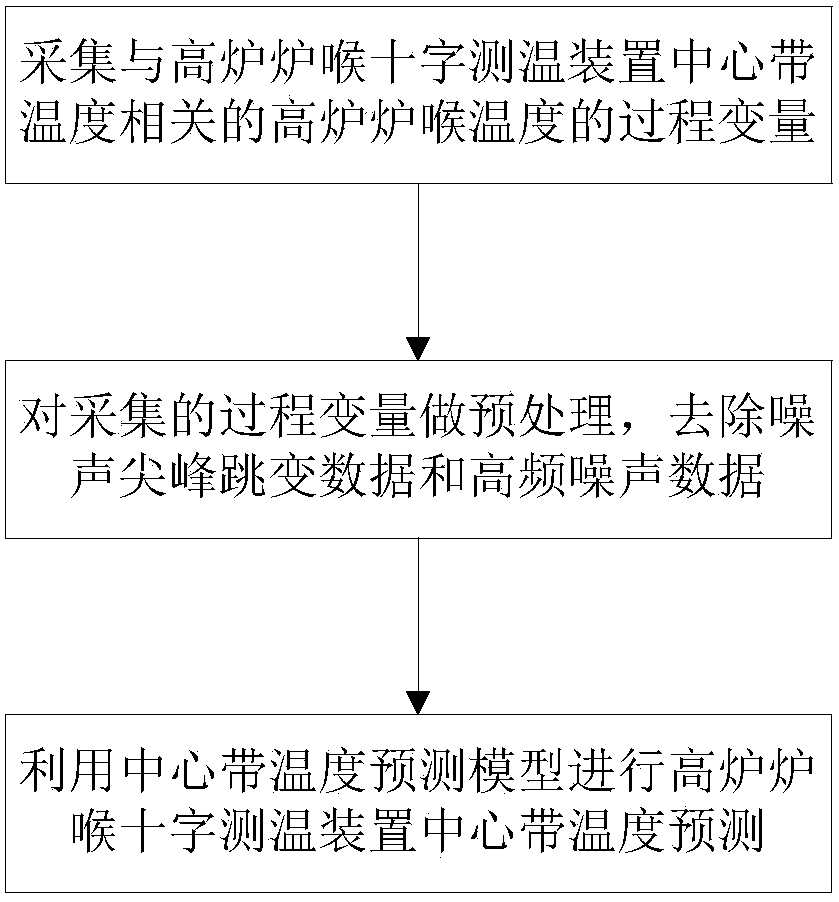

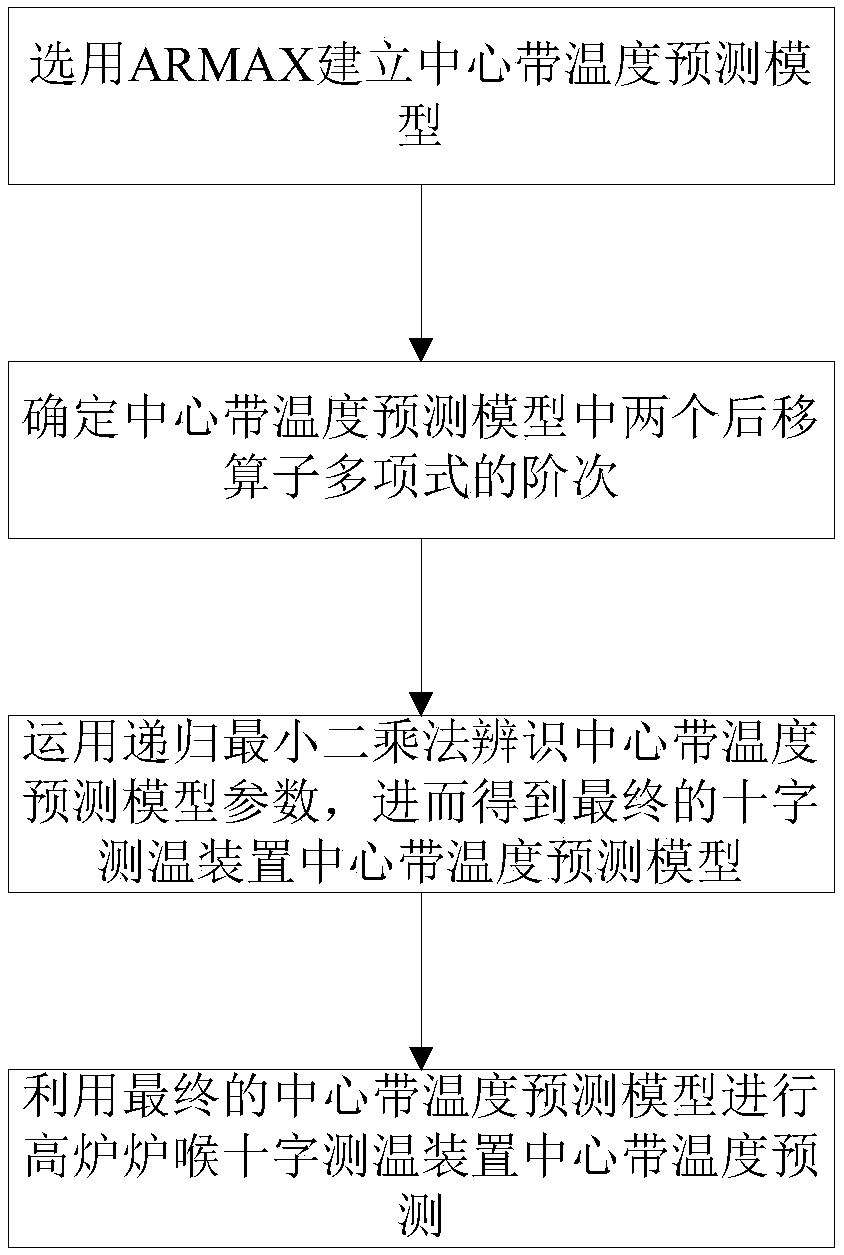

A technology for blast furnace throat and cross temperature measurement, which is applied to inspection devices and complex mathematical operations, can solve problems such as difficulties, time lags, and inability to make timely and correct adjustments, achieving high precision and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

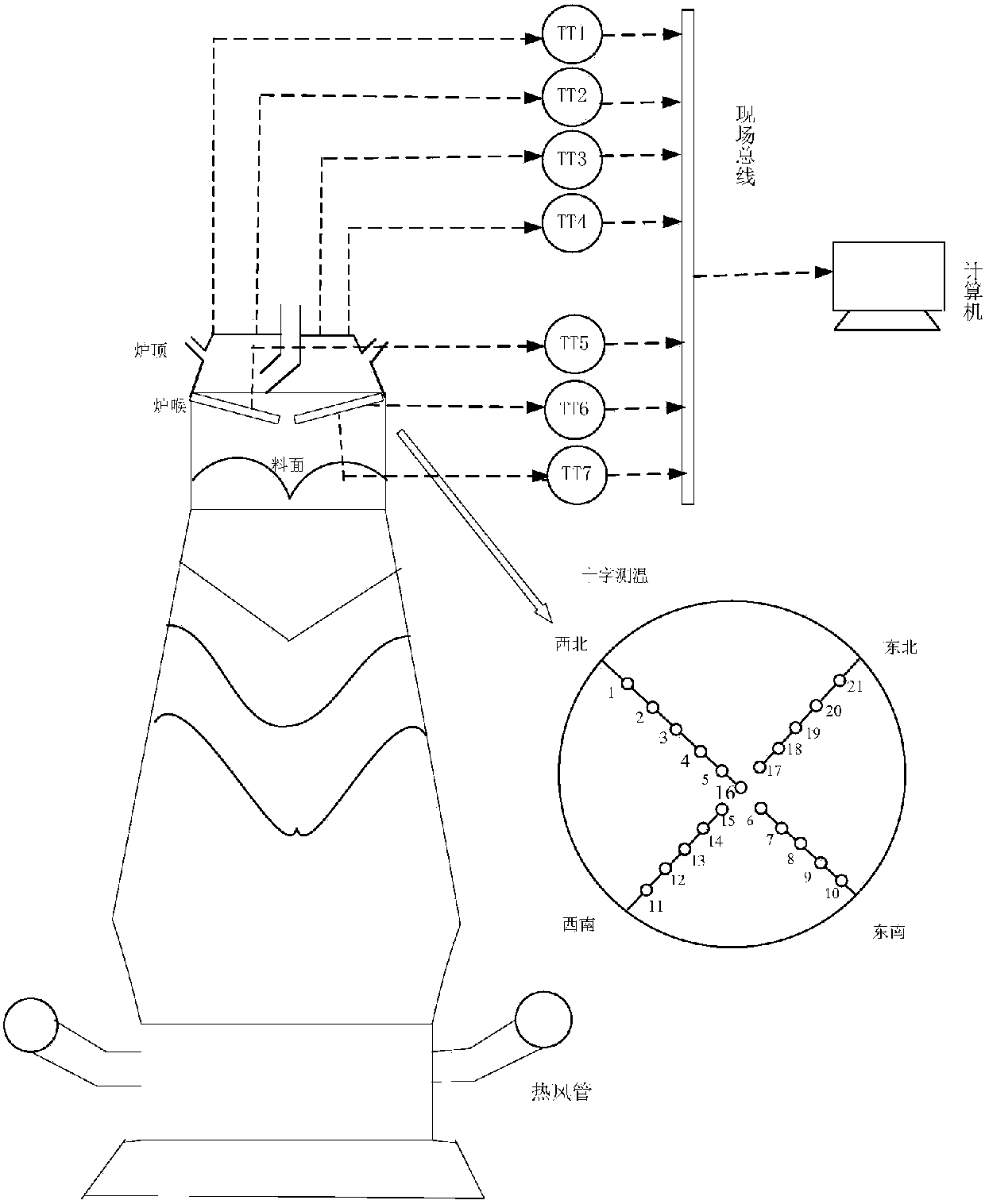

[0072] Such as figure 1 As shown, the blast furnace throat cross temperature measuring device is installed on the blast furnace throat or the cover in the form of a positive cross, including 4 cross temperature measuring guns, which are respectively installed in the four directions of the blast furnace throat in the northwest, southwest, southeast, and northeast. The serial numbers of the thermocouples on the cross temperature measuring gun are arranged as follows: from northwest to southeast, they are numbered 1 to 10; from southwest to northeast, they are numbered 11 to 21. The numbers of the cross temperature measuring guns are No. 1, No. 2, No. 3, and No. 4 clockwise from the southeast direction to the northeast direction. There are long and short cross temperature measuring guns, of which the northwest direction (No. 3) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com