Manual scanning electron microscope electron backscatter in-situ stretching device

A technology of electron backscattering and in-situ stretching, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of influence of motor vibration experiment results, cost increase, and high risk of electron microscopy, etc., and achieve high structural stability and high precision. The effect of small experimental error and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

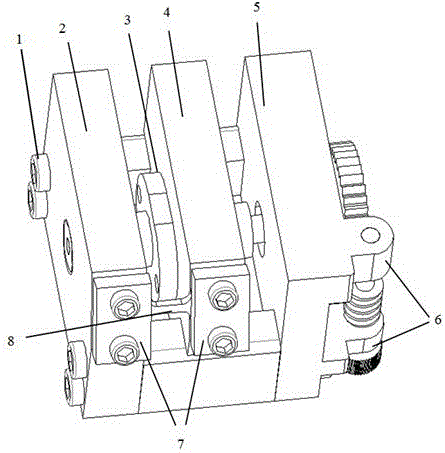

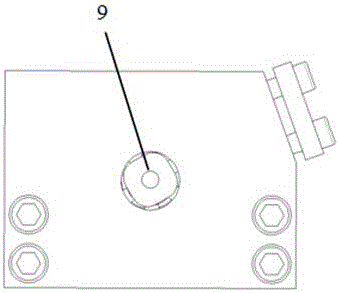

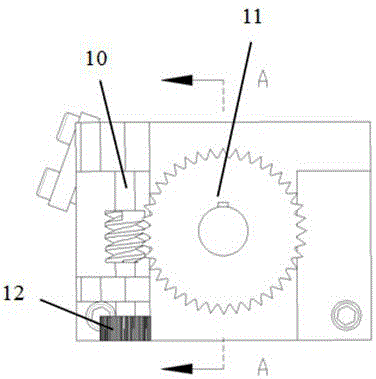

[0028] Such as figure 1 , figure 2 , image 3 and Figure 4 The electronic backscattering in-situ stretching device shown in the manual scanning electron microscope includes a slider 4, the left and right sides of the slider 4 are respectively provided with a fixing seat 2 and a supporting seat 5, the outer side of the fixing seat 2 is provided with a screw 1, and the center of the slider 4 is provided There is a ball screw nut 3, and a radial bearing 6 is arranged inside the support seat 5; a chuck 7 is installed at the front end of the fixed seat 2 and the slider 4, and the sample 8 is clamped on the chuck 7; the middle position of the side of the fixed seat 2 is set There is a lock nut 9 to prevent the ball screw from falling off; one side of the fixed seat 2 is provided with a worm 10, and the other side of the fixed seat 2 is provided with a deep groove ball bearing 15; the bottom of the worm 10 is provided with a knob 12; the inside of the support seat 5 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com