Electro hydraulic servo system heat balance determination method

An electro-hydraulic servo system and a technology for determining methods, which are applied in fluid pressure actuation system testing, fluid pressure actuation devices, mechanical equipment, etc., and can solve problems such as difficult thermal characteristics, many components of the servo system, and large temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

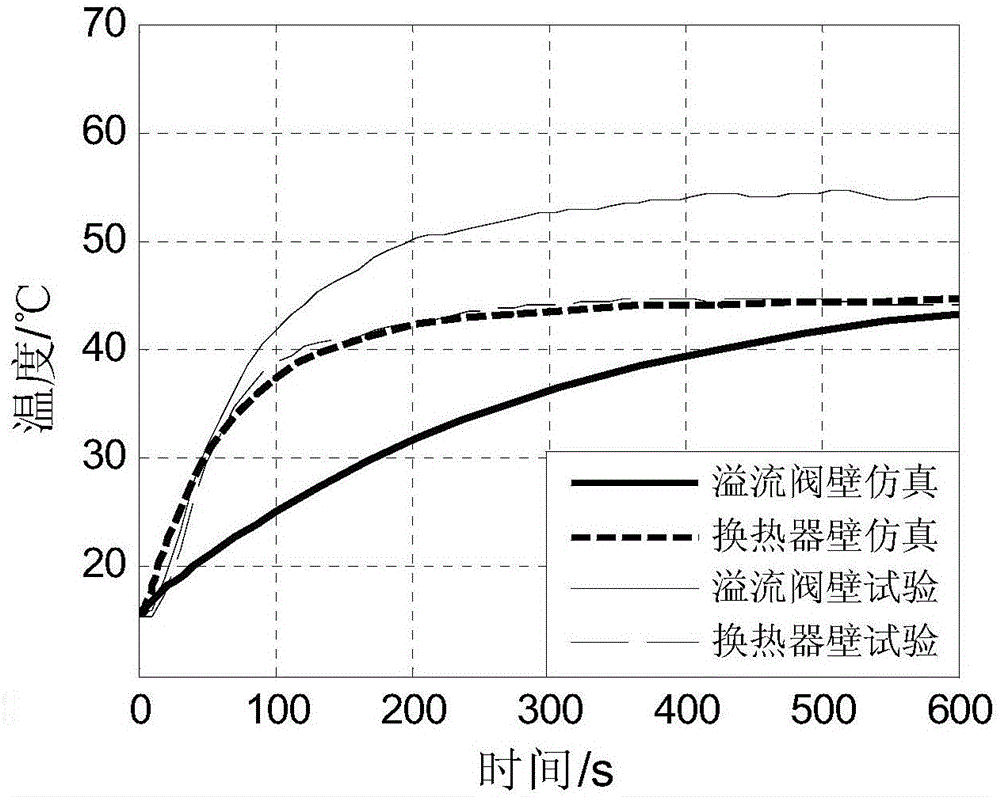

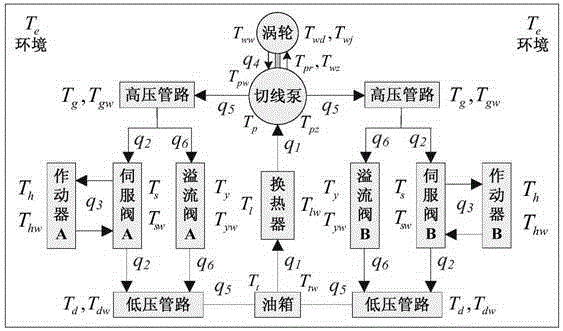

[0069] A certain type I level servo system is selected as the research object, and its thermal balance calculation and experimental research are carried out using the method of the present invention. The system is a one-to-two electro-hydraulic position servo system. According to the above 17 steps, the value of each parameter is completed. The equations are programmed under MATLAB and solved by the ode15s variable-order numerical differential algorithm to obtain 0~600 Second, the temperature of each node changes with time, and the simulation curve is analyzed, and the system quickly reaches an approximate thermal equilibrium state. The oil temperature in various places reaches equilibrium in about 30 seconds, and the temperature of each outer wall rises slowly after 100 seconds. When balancing, the temperature of the turbo mechanical seal is above 100°C, the temperature of the outer wall of the turbine and the pump support is around 0°C, and the temperature of the remaining ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com