Electric vehicle vacuum pump

A technology for electric vehicles and vacuum pumps, which is applied to pumps, piston pumps, pump components, etc., and can solve problems such as loud noise, easy leakage at the blockage, and changes in concentricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

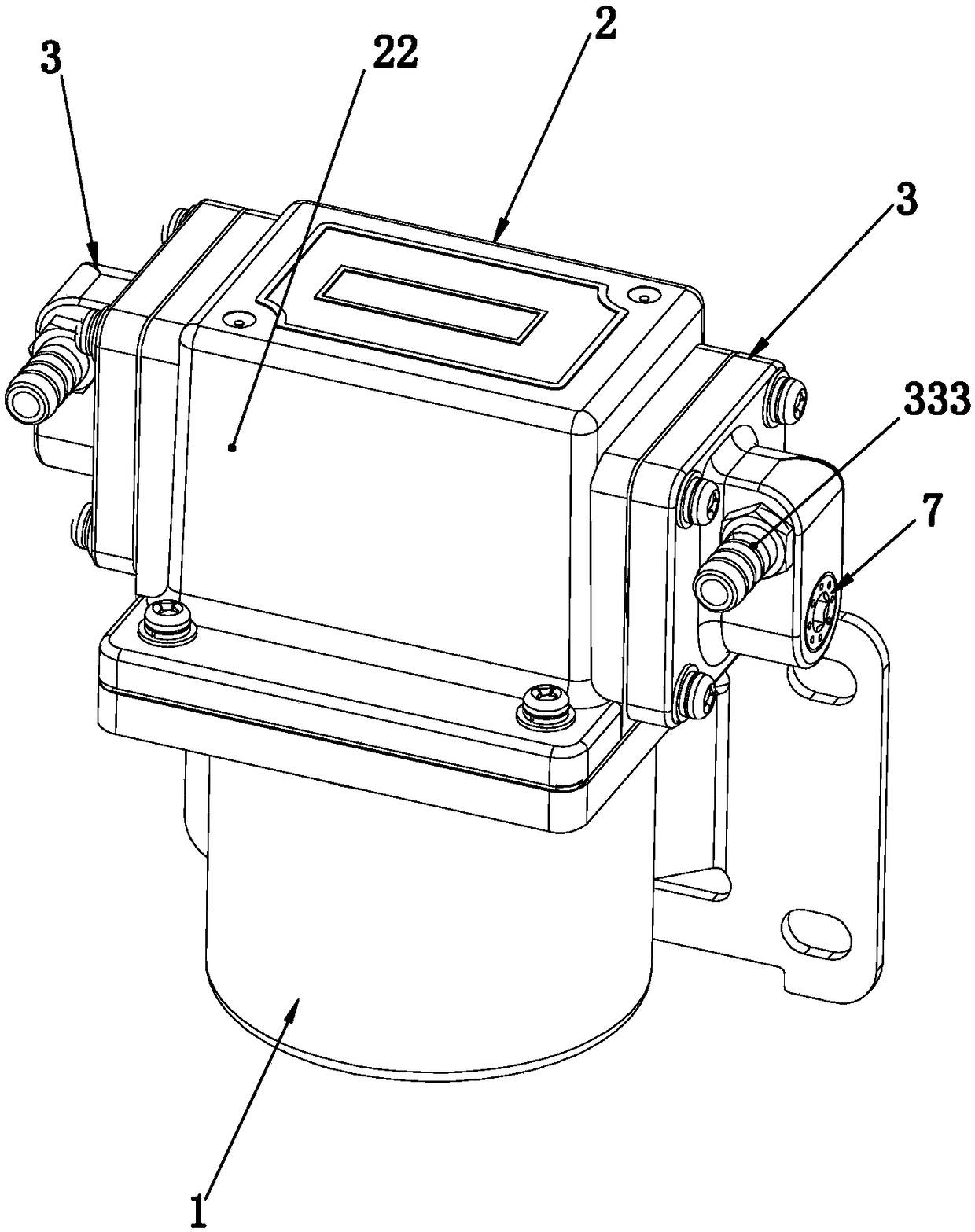

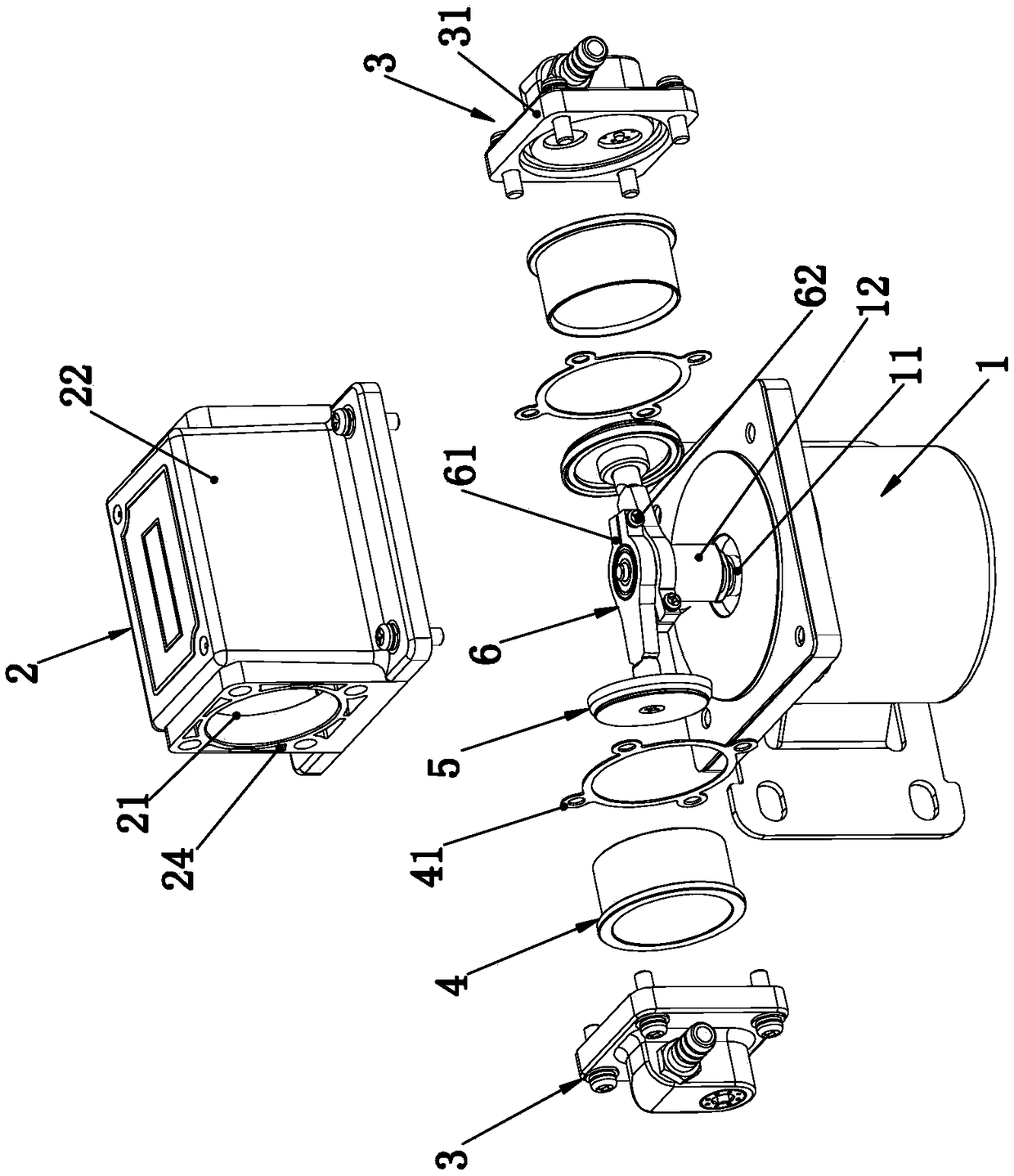

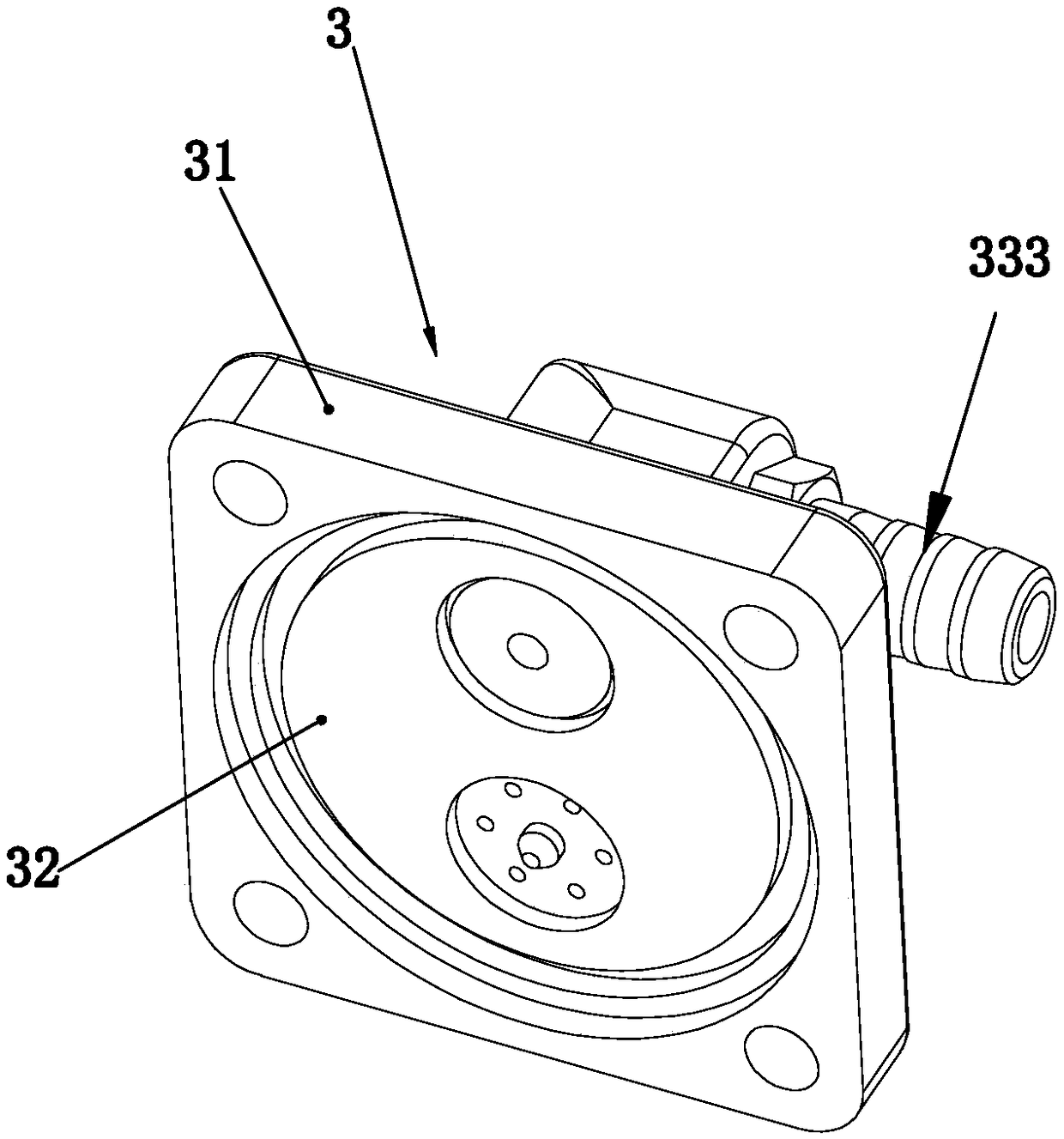

[0025] Such as figure 1 — Figure 7A vacuum pump for electric vehicles shown includes a motor 1, a pump casing 2 erected on the motor 1, an installation opening 21 is provided on the pump casing 2, a check valve 3 and a cylinder liner 4 are arranged at the installation opening 21, and The piston cup 5 that is linked with the motor 1 and can move back and forth in the cylinder liner 4, the piston cup 5 is connected with the motor shaft 11 of the motor 1 through the crankshaft 12 through the connecting rod 6, and the end connecting the connecting rod 6 and the crankshaft 12 has two pieces Open clamping pieces 61 are fixedly connected by fasteners 62 between the two clamping pieces 61, such as screws. The one-way valve 3 includes a one-way valve body 31, which is arranged on the one-way valve body 31 and connected with the cylinder. The connecting chamber 32 connected to the sleeve 4, the air intake passage 33 and the exhaust passage 34 connected with the connecting chamber 32, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com