Preparation method of functional ultra-high molecular weight polyethylene

A technology of ultra-high molecular weight and polyethylene, applied in the field of preparation of functional ultra-high molecular weight polyethylene, can solve the problems of frequent chain transfer reactions, decreased copolymerization activity, and inability to obtain functional ultra-high molecular weight polyethylene, etc., to achieve chain The effect of fast growth rate, good tolerance, and less β-hydrogen chain transfer reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

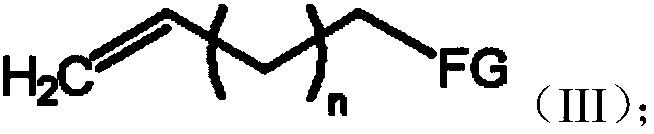

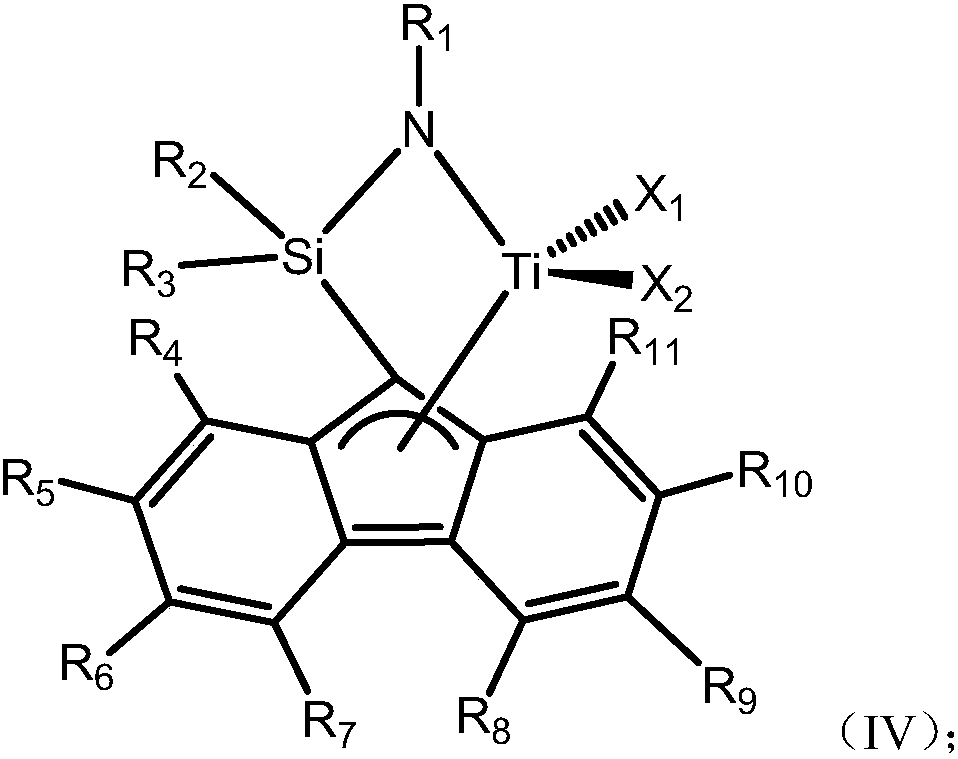

[0046] A preparation method of functional ultra-high molecular weight polyethylene, under nitrogen atmosphere, first add xylene, triisobutylaluminum and polar comonomer (n 9, FG is hydroxyl), the molar ratio of triisobutylaluminum to polar comonomer is 1.5:1; after stirring for 10min at 20°C, add modified methylalumoxane and have the structure of formula (IV) The fluorenylamine titanium complex (R 1 is adamantyl, R 2 and R 3 is methyl, R 4 ~R 10 is tert-butyl, R 11 is hydrogen, X 1 and x 2 is a methyl group), the molar ratio of the fluorenylamine titanium complex to the polar comonomer having the structure of formula (III) is 1:300, and the molar ratio of the fluorenylamine titanium complex to the modified methylaluminoxane is 1:1000; then unload the nitrogen in the kettle, and then feed ethylene gas to make the pressure in the kettle reach a certain value; stop feeding ethylene after the polymerization reaction at 30°C for 30 minutes, empty the gas in the kettle, and d...

Embodiment 7~11

[0050] A preparation method of functional ultra-high molecular weight polyethylene, under nitrogen atmosphere, firstly add toluene, triisobutylaluminum and polar co-monomer (n is 9, FG is hydroxyl), the molar ratio of triisobutylaluminum to polar comonomer is 1.5:1; after stirring at 20°C for 10min, add modified methylalumoxane and Fluorenylamine titanium complex (R 1 is tert-butyl, R 2 and R 3 is methyl, R 4 and R 5 for hydrogen, R 6 ~R 9 is tert-butyl, R 10 ~R 11 is hydrogen, X 1 and x 2 is methyl), the molar ratio of the fluorenylamine titanium complex to the modified methylaluminoxane is 1:1000; then the nitrogen in the kettle is removed, and then ethylene gas is introduced to make the pressure in the kettle reach 8bar; at 30°C Stop feeding ethylene after 30min of polymerization reaction under conditions, empty the gas discharge in the kettle, pour the reactant into the ethanol solution containing 10% (V / V) hydrochloric acid; filter the product obtained after was...

Embodiment 12~19

[0054] A preparation method of functional ultra-high molecular weight polyethylene, under nitrogen atmosphere, firstly add cyclooctane, triisobutylaluminum and polar comonomer ( FG is hydroxyl), the molar ratio of triisobutylaluminum to polar comonomer is 1.5:1; after stirring at 20°C for 10 minutes, add modified methylalumoxane and fluorenyl group having the structure of formula (IV) Amine titanium complex (R 1 is tert-butyl, R 2 and R 3 is methyl, R 4 ~R 10 is tert-butyl, R 11 is hydrogen, X 1 and x 2 is a methyl group), the molar ratio of the fluorenylamine titanium complex to the polar comonomer having the structure of formula (III) is 1:1000, and the molar ratio of the fluorenylamine titanium complex to the modified methylaluminoxane is 1:1000; then unload the nitrogen in the kettle, and then feed ethylene gas to make the pressure in the kettle reach 8bar, and the molar ratio of ethylene to polar comonomer is 150:1; stop the ventilation after the polymerization rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com