A capillary glass tube stacking device and method based on two-dimensional positioning holes of photonic crystal fiber structure

A photonic crystal fiber and capillary glass tube technology, which is applied in the field of fiber manufacturing, can solve the problems of affecting the properties of photonic bandgap fibers, reducing the axial uniformity of photonic bandgap fibers, and taking a long time to achieve mechanical automatic stacking, easy mechanical The effect of automated stacking and low operator requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

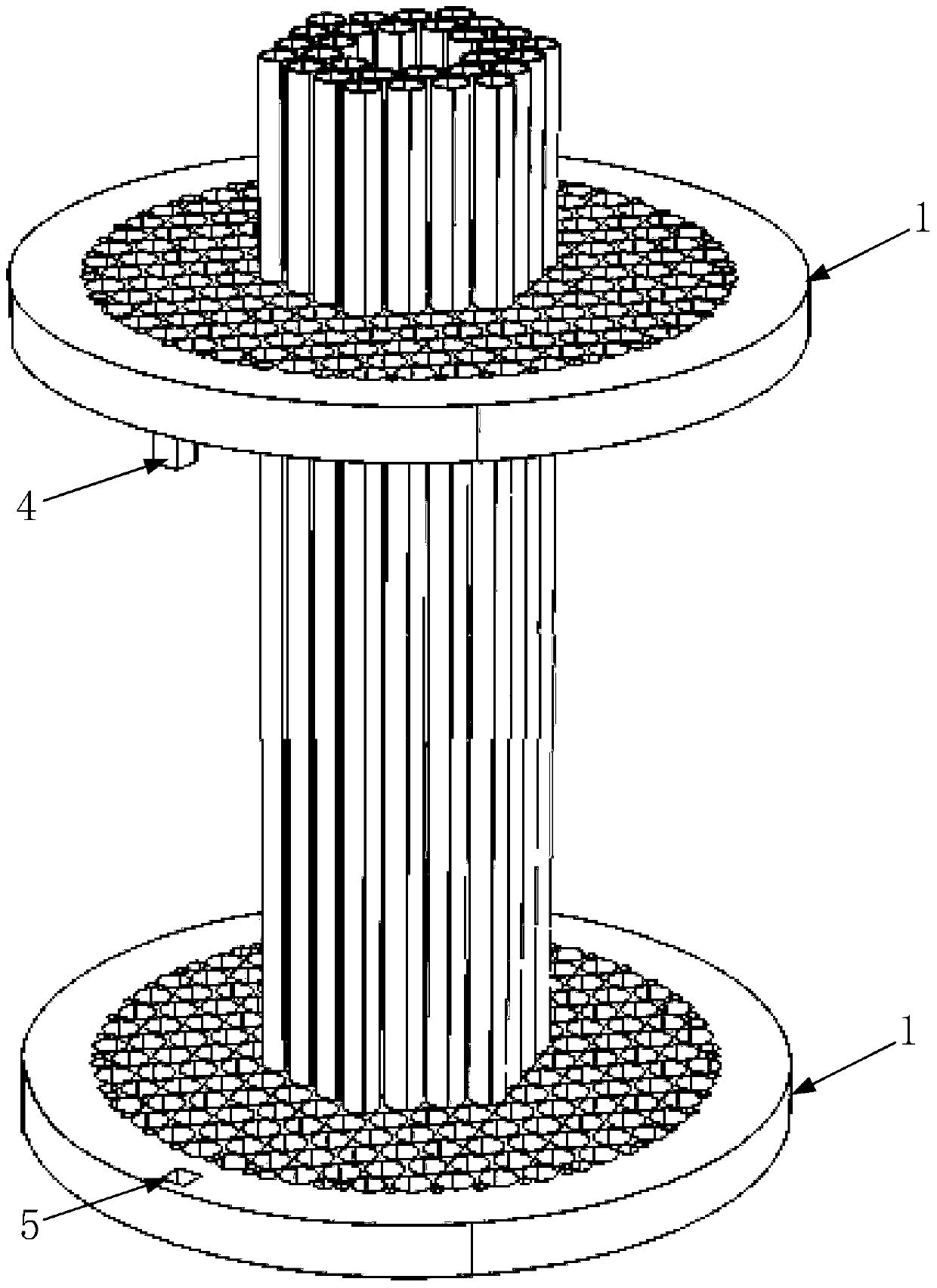

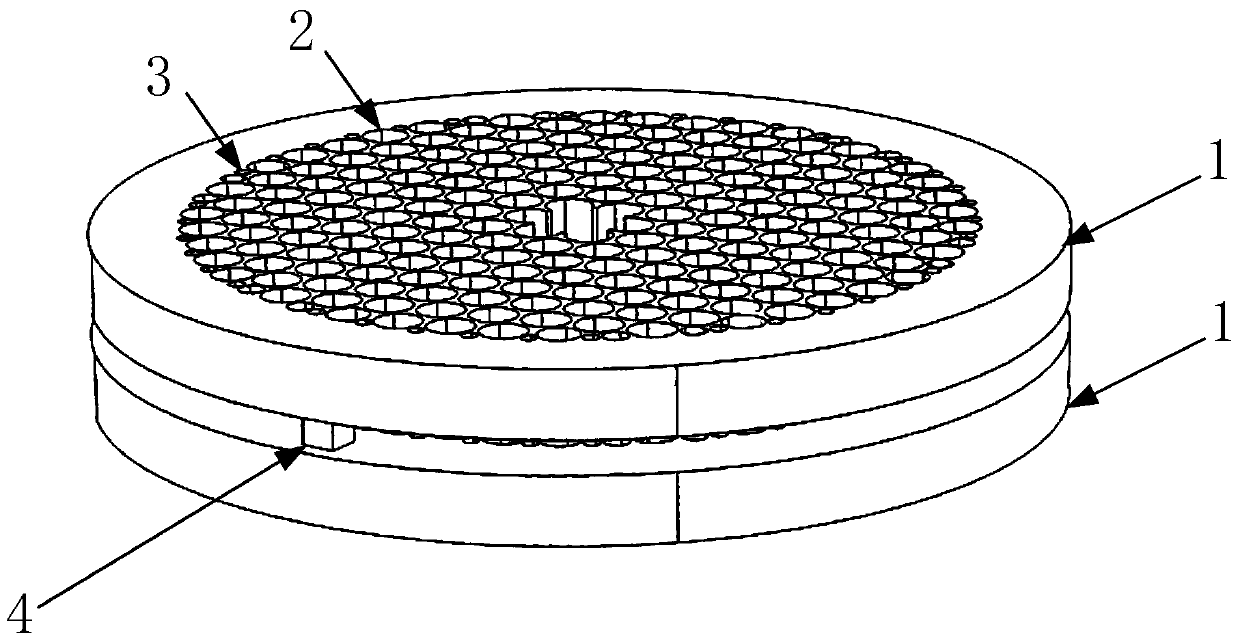

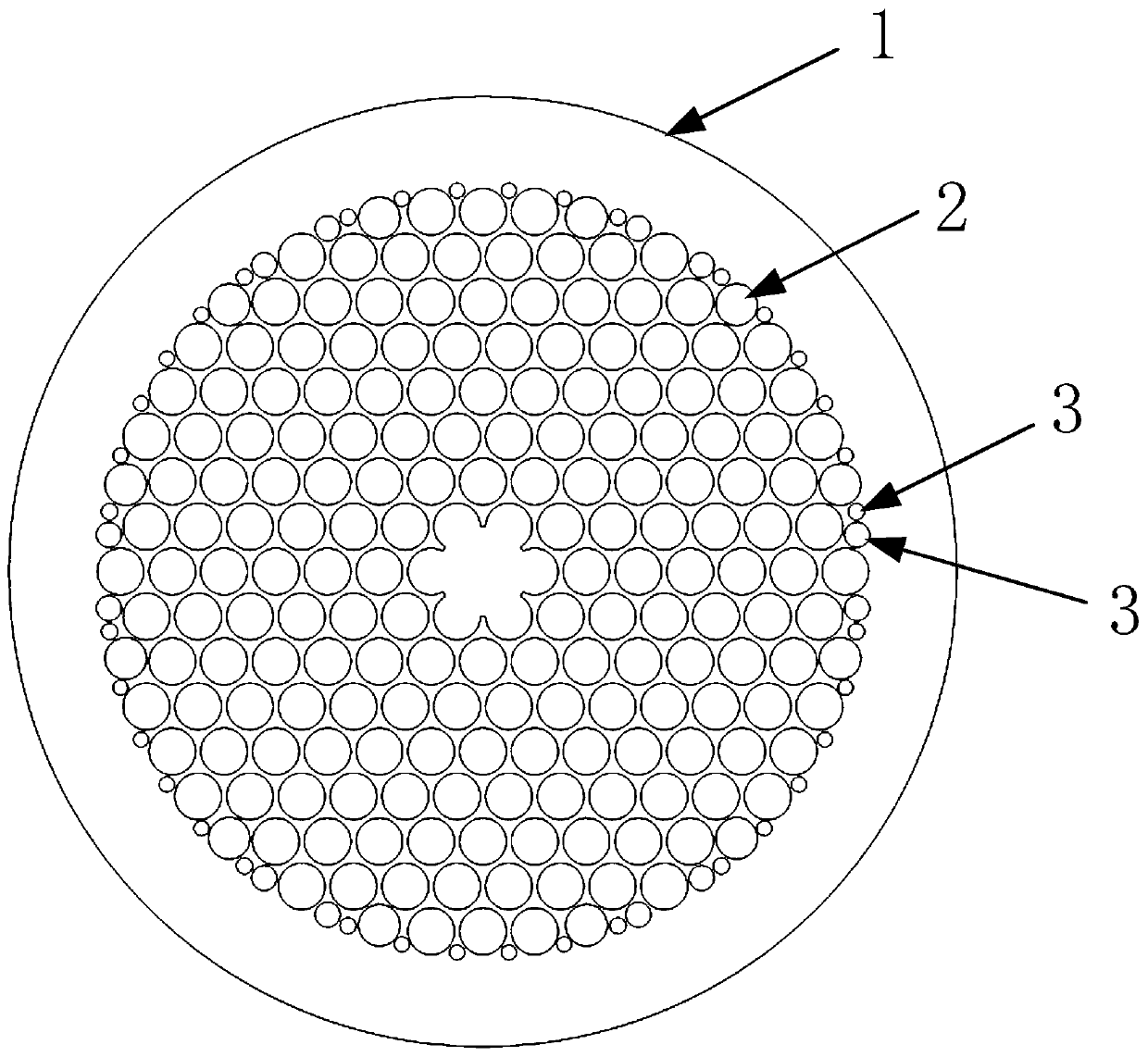

[0027] Such as image 3 As shown, positioning plate 1 is suitable for the photonic bandgap optical fiber with the most complicated preform structure, and its air hole cladding is arranged in a triangular lattice stacking manner, with 180 capillaries, and the middle 7 capillaries are removed, and the outer periphery of the preform There is also a capillary rod with a fixed diameter smaller than the capillary in the circumferential direction; therefore, using the punching technology, according to the structure of the preform on the positioning plate 1, according to the structure of the preform and the size of the capillary, punch holes radially along the positioning plate, and in the two Positioning pins 4 and positioning holes 5 are respectively installed on the positioning plate 1, thereby completing the stacking device corresponding to the photonic bandgap optical fiber. In order to simplify the drilling process and facilitate the removal of the capillary from the two positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com