Material taking gripper for bottle

A bottle and material grasping technology, which is applied in the field of bottle retrieving grippers, can solve problems such as potential safety hazards and bottle slippage, and achieve the effect of a firm structure of the retrieving gripper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

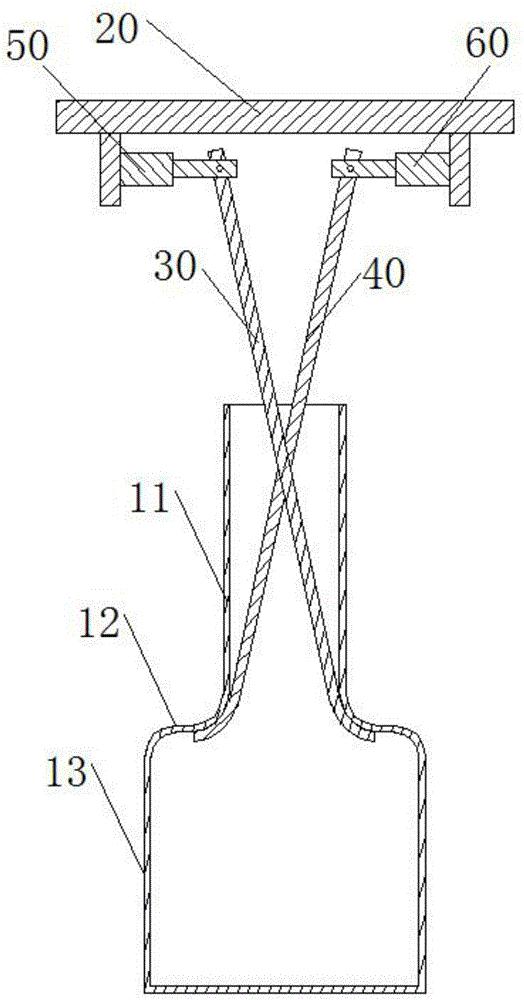

[0022] see figure 1 , as shown in the legend therein, a bottle retrieving gripper is used for retrieving the blown bottle product. The bottle includes a bottle neck 11, a bottle shoulder 12 and a bottle body 13. The first clamping rod 30 and the second clamping rod 40, the bottom of the top plate 20 is symmetrically installed with the first cylinder 50 and the second cylinder 60, the upper end of the first clamping rod 30 and the upper end of the second clamping rod 40 are opposite and connected respectively On the first cylinder 50 and the second cylinder 60, the lower end of the first clamping rod 30 is opposite to the lower end of the second clamping rod 40 and the two are respectively bent back to form a grapple matching the inner wall of the bottle shoulder 12, the first The cylinder 50 and the second cylinder 60 drive the first clamping rod 30 and the second clamping rod 40 respectively, so that the distance between the grapple free end of the first clamping rod 30 and t...

Embodiment 2

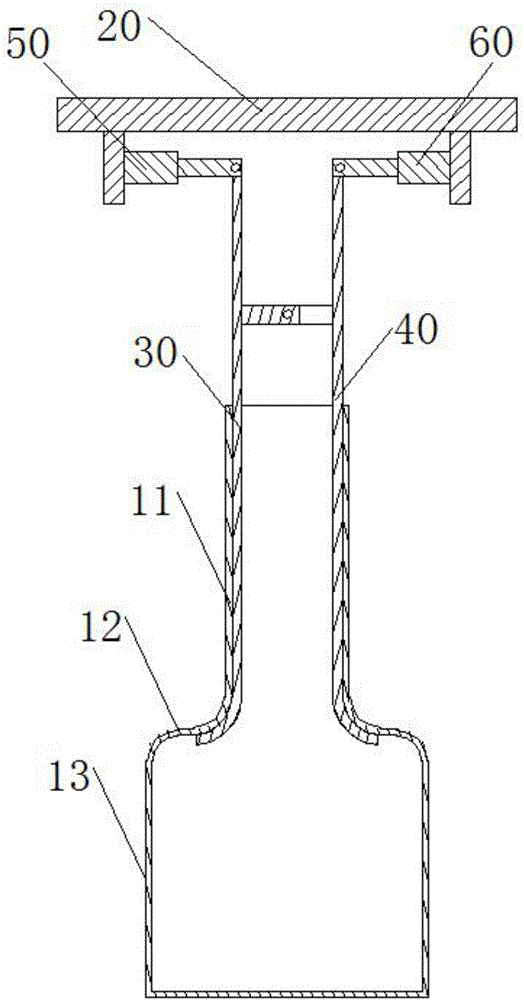

[0029] see figure 2 , as shown in the legend therein, the rest are the same as the first embodiment, the difference is that the first clamping rod 30 and the second clamping rod 40 are jointly connected on a shaft to form two lever structures, the first clamping rod 30 The upper end of the upper end and the upper end of the second clamping rod 40 are hingedly connected with the first air cylinder 50 and the second air cylinder 60 respectively.

[0030] The first clamping bar 30 and the second clamping bar 40 are substantially J-shaped respectively, and the two are arranged with their backs crossed. The lower end of the second clamping rod 40 is close, and the upper end of the first clamping rod 30 is far away from the upper end of the second clamping rod 40 so that the lower end of the first clamping rod 30 and the lower end of the second clamping rod 40 are separated.

Embodiment 3

[0032] see image 3 , as shown in the legend therein, the rest are the same as the second embodiment, the difference is that the first clamping rod 30 and the second clamping rod 40 are respectively substantially in the shape of a J, and the two are arranged with their backs facing each other, and the upper end of the first clamping rod 30 Close to the upper end of the second clamping bar 40 so that the lower end of the first clamping bar 30 and the lower end of the second clamping bar 40 are away from each other, and the upper end of the first clamping bar 30 and the upper end of the second clamping bar 40 are far away to make the first clamping bar The lower end of 30 is close to the lower end of the second clamping rod 40 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com