Optical coating and transfer printing combined surface treatment method

A processing method and a combined technology, applied in chemical instruments and methods, printing, printing devices, etc., can solve the problems of low appearance competitiveness and inability to achieve beautiful appearance, etc., so as to improve appearance competitiveness, rich and changeable visual effects, The effect of comfortable touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention provides a 2.5D glass surface treatment method combining optical plating and transfer printing. In order to make the purpose, technical solution and effect of the present invention clearer and more definite, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

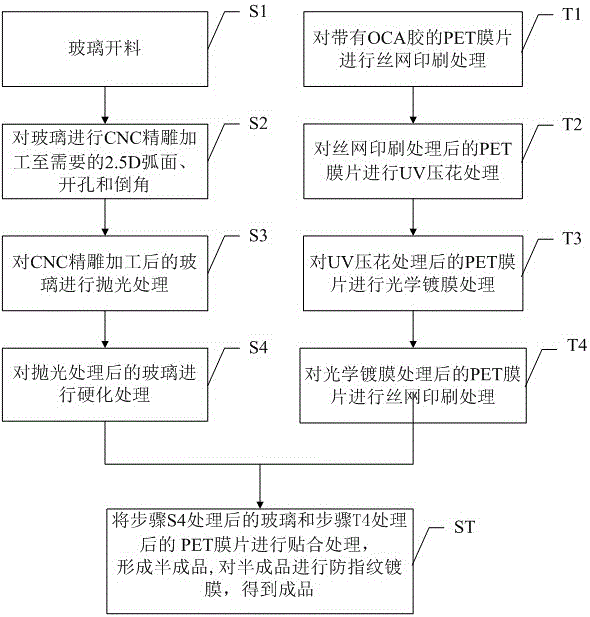

[0030] see figure 1 , figure 1 It is a flow chart of a preferred embodiment of a 2.5D glass surface treatment method combining optical plating and transfer printing of the present invention, as shown in the figure, which includes:

[0031] Step S1, glass cutting;

[0032] Step S2, Carrying out CNC engraving processing on the glass to obtain the required 2.5D curved surface, opening and chamfering;

[0033] Step S3, polishing the glass processed by CNC fine carving;

[0034] Step S4, hardening the polished glass;

[0035] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com