Plastic particle screening device

A screening device and technology for plastic particles, which are used in solid separation, separation of solids from solids by air flow, static electricity, etc., can solve problems such as easy upward movement, affecting the normal progress of screening work, and unfavorable passage of plastic particles through the screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

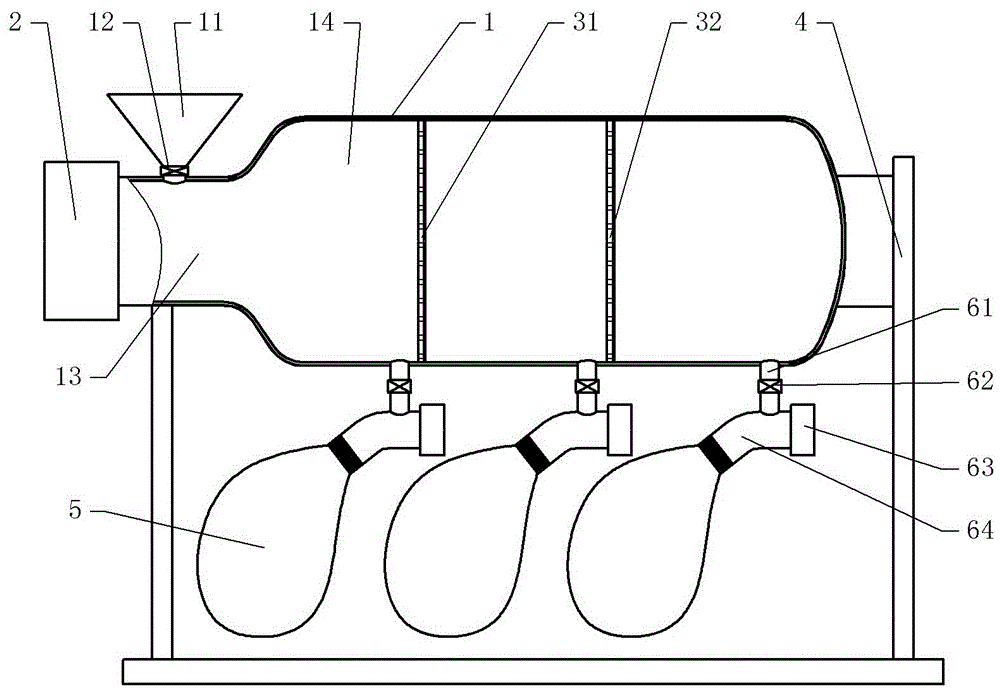

[0018] The reference signs in the drawings of the description include: main air duct 1, feeding fan 2, support 4, collecting bag 5, feeding hopper 11, regulating valve 12, feeding end 13, material selecting end 14, primary screen Net 31, secondary screen 32, discharge pipe 61, discharge valve 62, discharge fan 63, discharge air duct 64.

[0019] The embodiment is basically as figure 1 Shown:

[0020] The plastic particle screening device comprises a support 4, a feed hopper 11, a main air duct 1, a screen and a collection bag 5 made of non-woven fabric; the main air duct 1 is placed horizontally on the support 4, and the main air duct 1 is welded with the bracket 4; one end of the main air duct 1 is the feed end 13, the other end is the material selection end 14, the side wall of the feed end 13 is provided with a feed port, and the end of the feed end 13 is installed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com