Installation device of machining work table

A technology for machining and installing devices, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of inconvenient disassembly and assembly of machining workbench, troublesome disassembly and assembly, and shortened life, so as to improve the benefit of reuse , Firm fixation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

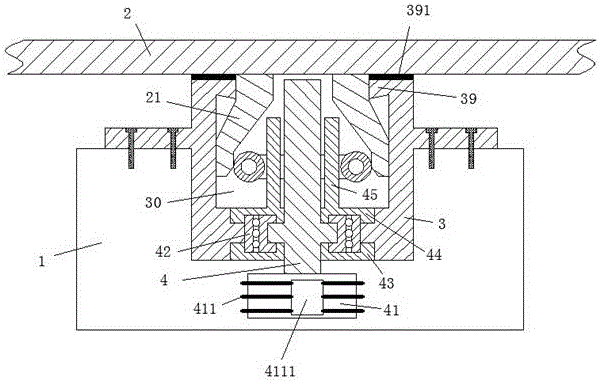

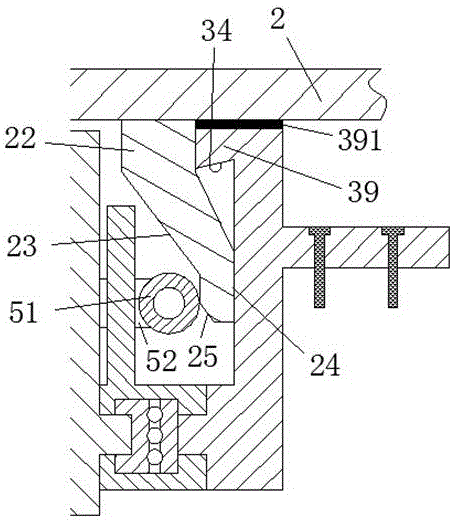

[0008] Combine below Figure 1-2 The present invention will be described in detail.

[0009] A machining workbench installation device according to an embodiment of the present invention is used to fix the workbench 2 on the support frame body 1, including the support frame body 1 and the workbench 2 connected to the support frame body 1, The support frame body 1 is fixedly provided with a bearing part 3 with a hollow cavity 30 inside, and the workbench 2 is integrally provided with two deformable connectors 21 symmetrically distributed from left to right, and the two deformable connectors The member 21 is used to be inserted into the hollow cavity 30 of the carrying part 3 through elastic deformation, and the top of the carrying part 3 is provided with an elastic pad 391 for when the two deformable connecting parts 21 are elastically deformed. When inserted into the hollow cavity 30 of the bearing part 3, it plays a buffering role, preventing the bottom surface of the workbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com