Hollow fiber nanofiltration membrane based on epsilon-polylysine and preparation method of hollow fiber nanofiltration membrane

A technology of polylysine and nanofiltration membrane, which is applied in the field of filter materials, can solve the problems of long cross-linking process, low preparation efficiency, hidden safety hazards, etc., and achieve the effect of simple preparation method, long stability and good separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

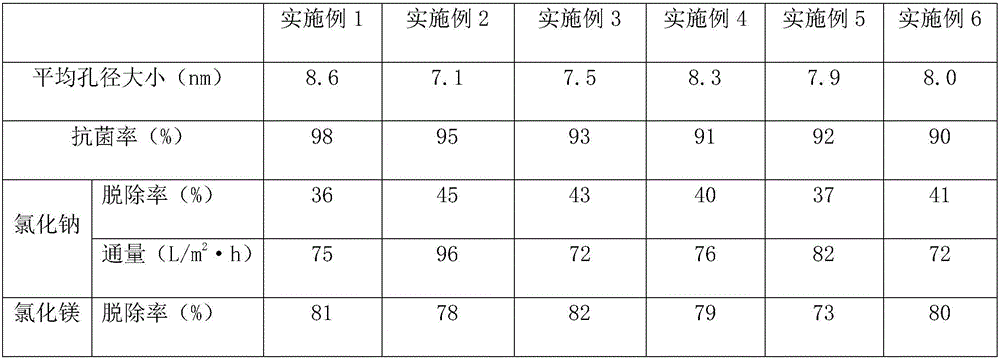

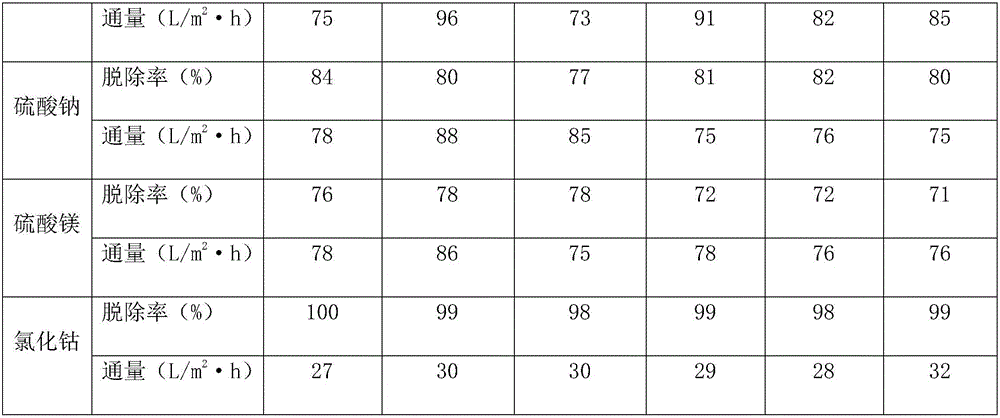

Examples

Embodiment 1

[0032] (1) configure the polyallyl ammonium chloride solution and the ε-polylysine solution of 0.2% respectively with a mass percentage concentration of 0.2%, add a certain amount of sodium chloride respectively, so that the concentration of sodium chloride is 0.5M , adjust the pH value of the polyallyl ammonium chloride solution to 2.5, and the pH value of the ε-polylysine solution to 7.5.

[0033] (2) Prepare a sodium polystyrene sulfonate solution with a mass percent concentration of 0.4%, add a certain amount of calcium chloride to make the concentration of calcium chloride 0.5M, and adjust the pH value of the solution to 2.5.

[0034] (3) the sulfonated polysulfone hollow fiber membrane with a molecular weight cut-off of 50,000 is a support membrane, fixed in a container with a porous support layer, the membrane face is facing up, then in the container, add cationic polyelectrolyte solution, add The pressure is 0.1MPa, the cationic polyelectrolyte is combined with the sup...

Embodiment 2

[0041] (1) It is 0.2% poly-N, N-dimethyl diallyl ammonium chloride solution and 0.6% epsilon-polylysine solution to configure mass percentage concentration respectively, add a certain amount of sodium chloride respectively, make The concentration of sodium chloride is 0.5M, adjust the pH value of polyallyl ammonium chloride, poly N,N-dimethyldiallyl ammonium chloride solution to 2.5, and the pH value of ε-polylysine solution is 10.5.

[0042] (2) Prepare a polyethylene sulfate solution with a mass percentage concentration of 0.4%, add a certain amount of calcium chloride to make the concentration of calcium chloride 0.5M, and adjust the pH value of the solution to 2.5.

[0043] (3) The sulfonated polyethersulfone hollow fiber ultrafiltration membrane with a molecular weight cut-off of 30,000 is used as a support membrane, fixed in a container with a porous support layer, and the membrane is facing up, and then the cationic polyelectrolyte is added to the container Solution, p...

Embodiment 3

[0050] (1) Configure the polyallyl ammonium chloride solution and the ε-polylysine solution of 0.4% respectively with a mass percent concentration of 0.2%, add a certain amount of sodium chloride respectively, so that the concentration of sodium chloride is 0.5M , adjust the pH value of the polyallyl ammonium chloride solution to 2.5, and the pH value of the ε-polylysine solution to 8.5.

[0051] (2) Prepare a polyacrylic acid solution with a mass percent concentration of 0.4%, add a certain amount of calcium chloride to make the calcium chloride concentration 0.5M, and adjust the pH value of the solution to 2.5.

[0052] (3) the sulfonated polysulfone hollow fiber membrane with a molecular weight cut-off of 40,000 is a support membrane, fixed in a container with a porous support layer, with the membrane facing up, then adding cationic polyelectrolyte solution to the container, adding The pressure is 0.2 MPa, the cationic polyelectrolyte is combined with the supporting membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com