Bipolar-plate type unit high-energy lead-acid battery, high-voltage battery pack formed from same and package method of high-voltage battery pack

A technology of lead-acid batteries and unit batteries, which is applied in the direction of lead-acid batteries, lead-acid battery construction, batteries with bipolar electrodes, etc., and can solve the problems of weak current density, electrochemical reaction depth difference, cascade internal resistance too large, Short life of lead-acid batteries and other problems, to achieve the effect of improving resource utilization, improving mechanical strength, and increasing hydrogen evolution potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

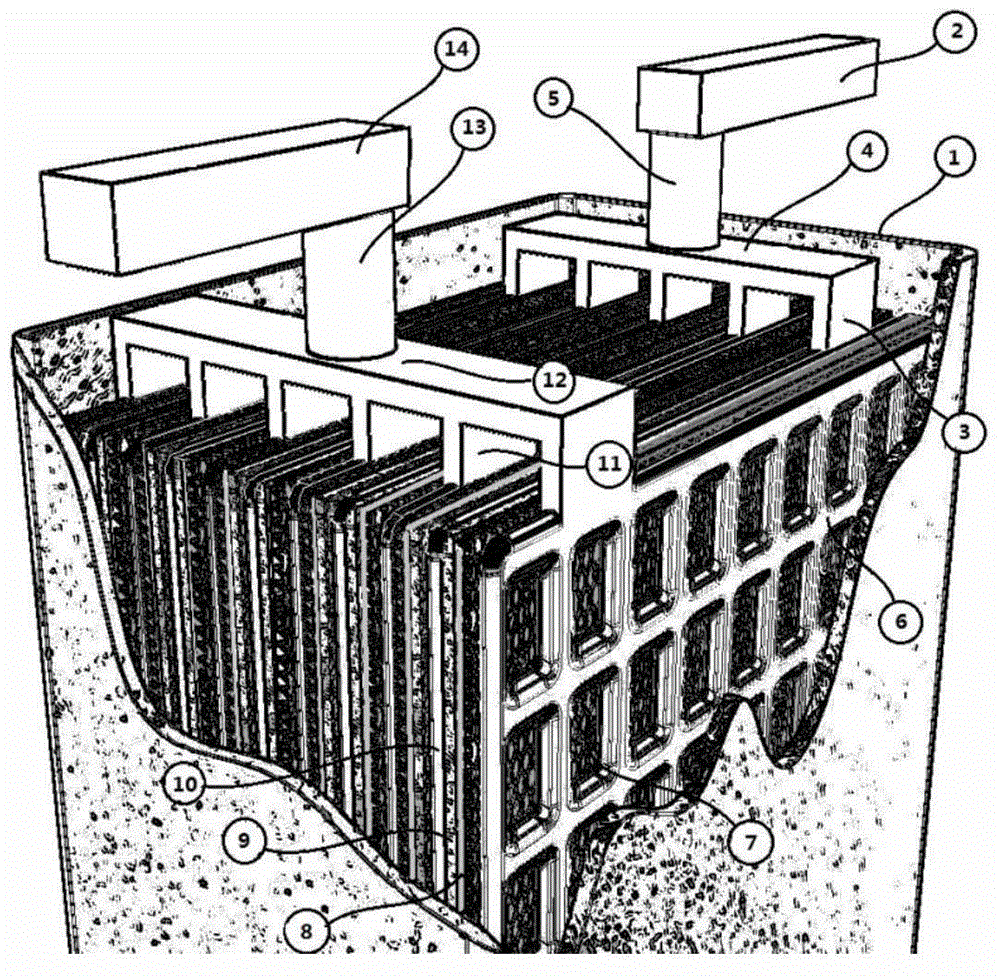

[0105] Below in conjunction with accompanying drawing, the implementation process of the present invention is described in detail:

[0106] It should be pointed out that, in the case of no conflict, the embodiments of the present application and various technical features in the embodiments and their derivative methods can be combined to form a variety of embodiments that are not in the description of the present invention, but these are all The embodiment of the essence and spirit of the invention also constitutes the protection scope of the present invention. The specific description of this embodiment does not limit other possible embodiments, and the following will make specific explanations with reference to the accompanying drawings and in combination with the embodiments.

[0107] In order to understand the improvement intention of the present invention to traditional lead-acid battery, first with figure 1 - Figure 5 illustrates the structure of a conventional lead-aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com