Wavelength conversion device, fluorescent color wheel and light-emitting device

A technology of wavelength conversion device and wavelength conversion material, which is applied in optics, optical components, nonlinear optics, etc., can solve the problems of temperature rise and phosphor luminous efficiency decline, and achieve the reduction of medium temperature rise, increase of density and Effect of thermal conductivity and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

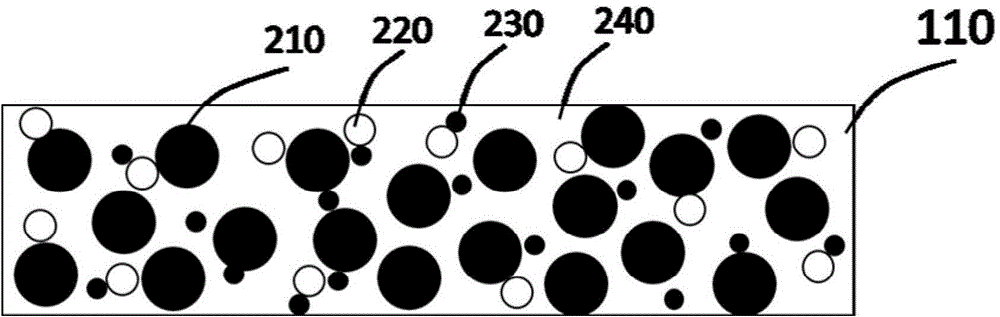

[0017] See figure 1 , figure 1 It is a schematic structural diagram of a wavelength conversion device according to Embodiment 1 of the present invention. The wavelength conversion device includes a light-emitting-reflective layer 110, and the light-emitting-reflective layer 110 includes a wavelength converting material 210, titanium oxide particles 220, aluminum oxide particles 230, and an adhesive 240. The light emitting-reflecting layer 110 not only has the function of reflecting incident light, but also has the function of emitting light after being excited.

[0018] Wherein, the wavelength conversion material is used to convert the wavelength of the excitation light from the excitation light source into the received light, and the wavelength conversion material 210 is distributed in the light emitting-reflecting layer 110 to form a light emitting center and a heat generating center. Titanium oxide particles 220 and aluminum oxide particles 230 play a reflective role and a...

Embodiment 2

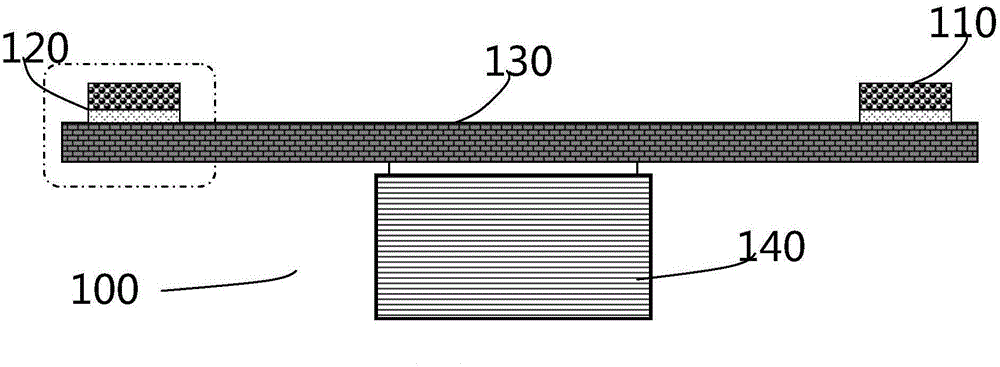

[0028] See figure 2 , figure 2 It is a schematic structural diagram of the wavelength conversion device according to the second embodiment of the present invention. Wherein the wavelength converting device includes a light emitting-reflecting layer 110 and a substrate 130 .

[0029] The light emitting-reflecting layer 110 is set according to the first embodiment, the substrate 130 is an aluminum nitride ceramic substrate, the substrate has high thermal conductivity, and has better bonding performance with the light emitting-reflecting layer 110 including aluminum oxide and titanium oxide.

[0030] In other modified embodiments, the substrate 130 may also be other ceramic substrates, such as alumina substrates, boron nitride substrates, silicon nitride substrates, silicon carbide substrates, and beryllium oxide substrates.

[0031] The substrate 130 can also be a metal substrate, such as an aluminum substrate or a copper substrate, and the metal substrate has better thermal...

Embodiment 3

[0034] See image 3 , image 3 It is a schematic structural diagram of a three-wavelength conversion device according to an embodiment of the present invention. The wavelength conversion device includes a light-emitting-reflective layer 110 , a purely reflective layer 120 and a substrate 130 . Compared with Embodiment 2, the difference of Embodiment 3 is only that the pure reflective layer 120 located between the luminescent-reflective layer 110 and the substrate 130 is added, and the pure reflective layer 120 is used to reflect the light passing through the luminescent-reflective layer 110 go back.

[0035]The pure reflective layer 120 includes aluminum oxide, titanium oxide and an adhesive, which is the same adhesive as the luminous-reflective layer, so that the two layers can be tightly bonded without peeling due to external force or temperature changes. Phenomenon.

[0036] Alumina has excellent reflectivity for visible light, and the reflectivity of pure alumina layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com