Non-fipple flute

A flute body and round hole technology, used in the field of wind instruments, can solve the problems of sound transmission obstacles, unsmooth playing sound, unsmooth airflow, etc., and achieve the effects of easy playing, stable sound and strong musical expression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

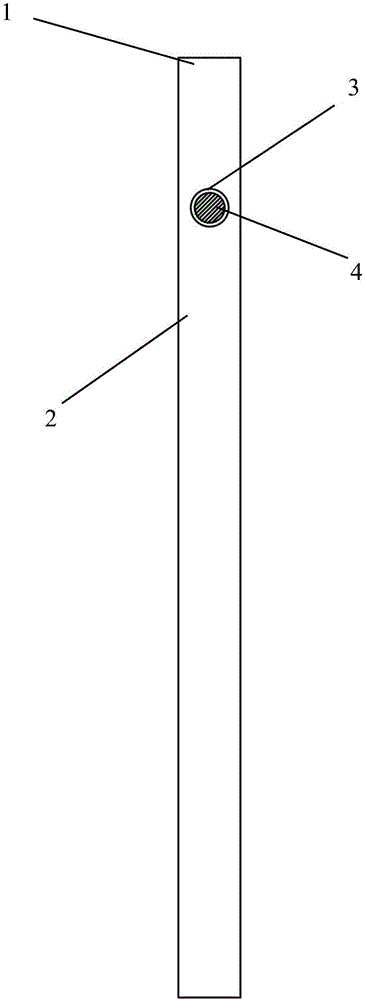

[0027] figure 1 As shown, a flute without holes, the mouthpiece 1 is located at one end of the flute body 2, and the feature is that: the side of the flute body 2 is provided with an opening 3, and a vibrating membrane 4 is installed in the opening 3.

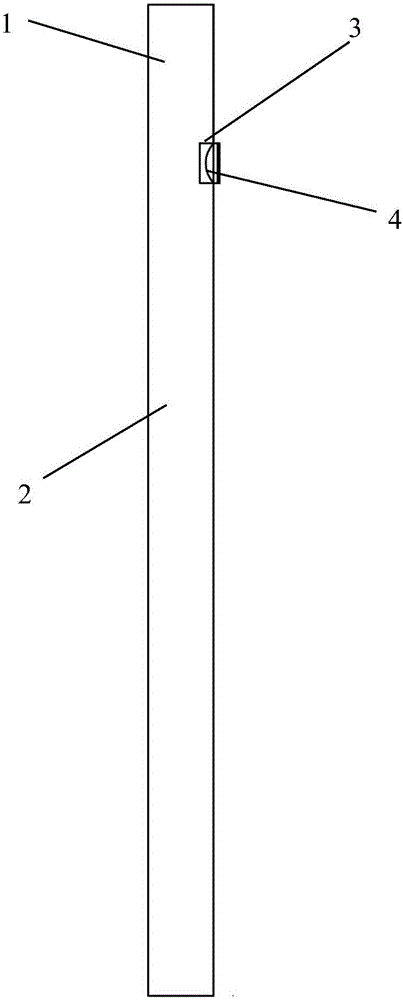

[0028] figure 2 As shown, a flute without holes, the opening 3 is equipped with an outwardly protruding boss 5, the boss 5 covers the vibrating membrane 4, and the boss 5 is equipped with a vibrating ring 6, the vibrating ring 6 Fasten the vibrating membrane 4 on the boss 5 .

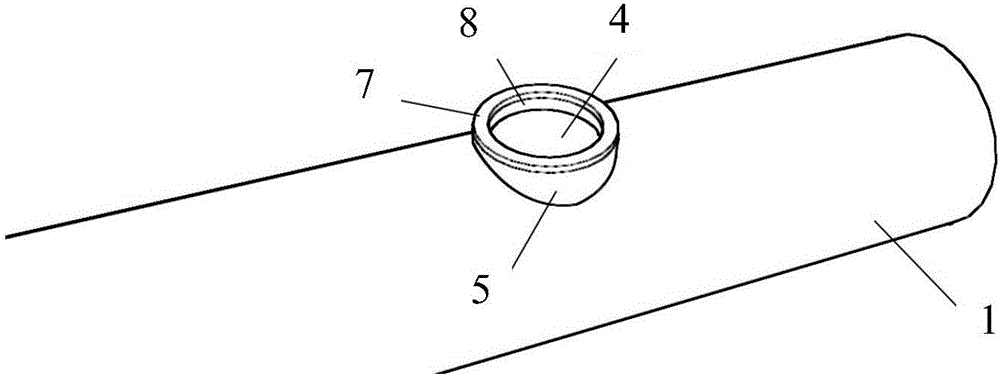

[0029] image 3 As shown, a flute without holes, the vibrating ring 6 includes an outer copper sleeve 7 and an inner copper sleeve 8, the vibrating film 4 is installed on the inner copper sleeve 8, and the inner copper sleeve 8 is installed on the inner wall of the boss 5, and the The outer copper sleeve 7 is crimped on the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com