Electric-arc furnace safety cooling system for producing refractory materials

A technology of cooling system and refractory materials, which is applied in the field of refractory material production, can solve the problems that the cooling water cannot be reused, boils, and personnel cannot enter the production area, so as to achieve good production application value and environmental protection value, and avoid equipment loss. The effect of high utilization rate of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

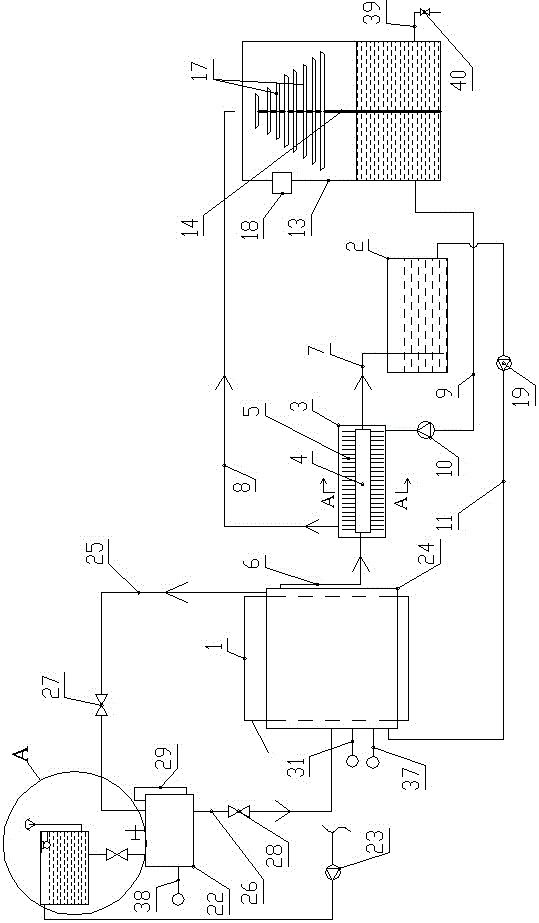

[0027] figure 1 The direction indicated by the middle arrow is the flow direction of the fluid.

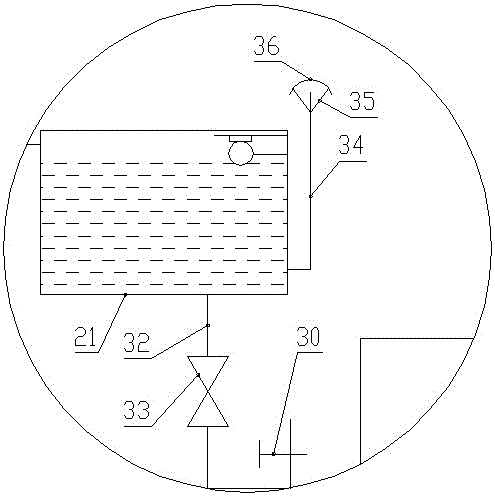

[0028] Such as Figure 1 to Figure 5 As shown, the electric arc furnace safety cooling system for producing refractory materials of the present invention includes an electric arc furnace 1, a heat exchanger, a water storage tank 2, a cooling tower, a high water tank 21, a water replenishment tank 22 and a water replenishment pump 23 arranged in a sealed manner;

[0029] The electric arc furnace 1 is provided with a water jacket 24 for cooling the electric arc furnace 1; the electric arc furnace 1 and its water jacket 24 are conventional technologies in the field, and the specific structure will not be described in detail.

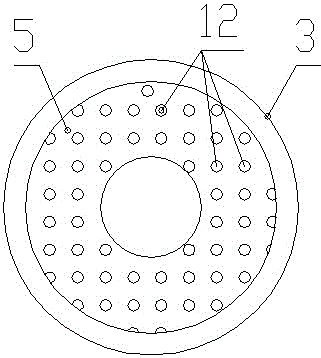

[0030] The heat exchanger includes a heat exchange box 3, in which an inner tube 4 is arranged along the length direction of the heat exchange box 3, and a number of heat exchange discs 5 are evenly spaced on the outer surface of the inner tube 4; the water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com