An electric oil-free main air compressor

An air compressor and electric technology, which is applied in the field of air compressors and electric oil-free main air compressors, can solve the problems of high daily maintenance costs, oil leakage and oil leakage of air compressors, and reduce vibration shock and vibration and noise, improving the overall intensity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

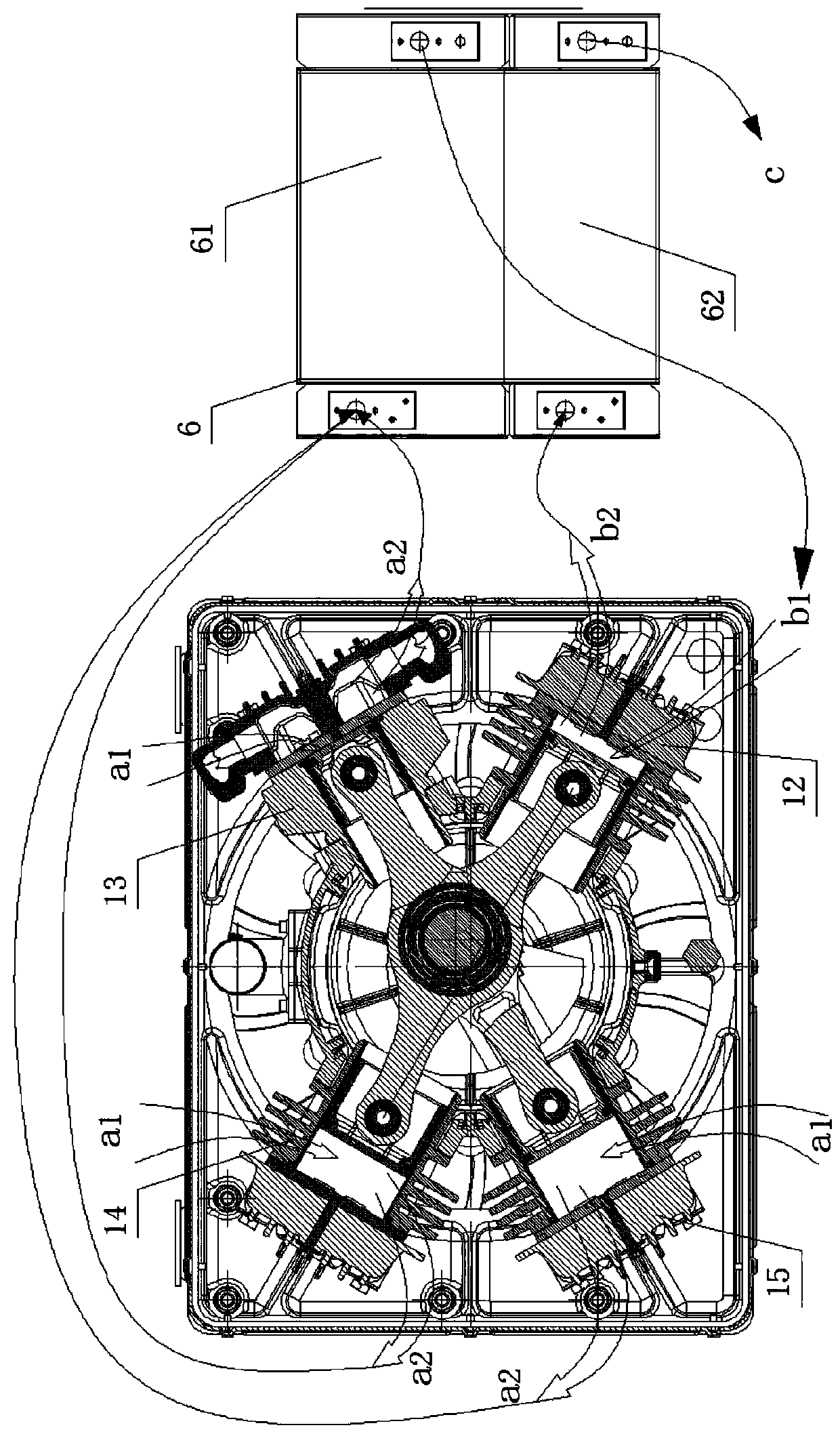

[0030] like figure 1 and figure 2 As shown, the electric oil-free main air compressor of this embodiment 1 includes a fan 2, an air compressor main body 3, a motor 5, a cooler 6, a shock absorber 8, a drainage solenoid valve 9, a pull rod 10 and a casing 18, The fan 2 is installed on the air compressor main body 3 through the fan bracket 1, the air compressor main body 3 and the motor 5 are connected through the coupling 4, the motor 5 and the cooler 6 are connected through the motor bracket 7, and the cooler 6 includes intermediate cooling There are at least two shock absorbers 8 installed on the fan support 1 and the motor support 7 respectively, the shock absorbers 8 are connected with the car body, and the drain solenoid valves 9 are respectively installed on the intercooler 61 and the aftercooler 62. The lower end of the aftercooler 62, the pull rod 10 connects and locks the motor support 7 and the main body of the air compressor 3, and a sound-absorbing material layer ...

Embodiment 2

[0041] The main features of this embodiment 2 are: the compression cylinder assembly is composed of two high-pressure cylinder assemblies 12 and two low-pressure cylinder assemblies, the high-pressure cylinder assembly 12 and the low-pressure cylinder assembly are arranged at intervals around the crankshaft 16, one high-pressure cylinder assembly 12 and one low-pressure cylinder assembly The cylinder assemblies are symmetrically arranged on both sides of the crankshaft 16, and a high-pressure cylinder assembly 12, a low-pressure cylinder assembly, another high-pressure cylinder assembly 12, and another low-pressure cylinder assembly are flat X-shaped. All the other features are with embodiment 1.

[0042] In Example 1 and Example 2, as figure 1 As shown, four shock absorbers 8 are installed on the fan support 1 and the motor support 7 respectively, and the shock absorbers are equipped with rubber springs to reduce the vibration impact of the vehicle to the main air compressor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com