Industrial tail gas liquefaction energy storage power generation system and power generation method

A technology for industrial tail gas and power generation systems, applied in liquefaction, refrigeration and liquefaction, machines/engines, etc., can solve the problems of exhaust resource waste, environmental pollution, high cost, etc., and achieve resource saving, safety improvement, high efficiency, energy saving and emission reduction The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

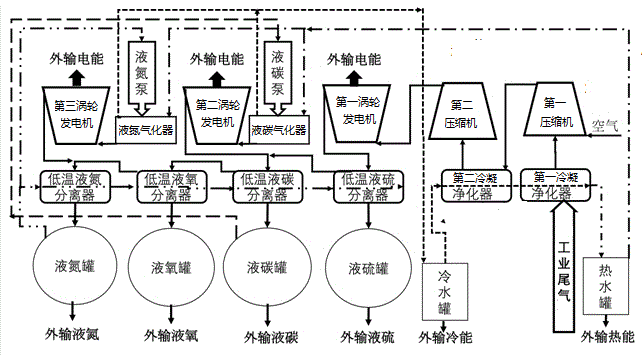

[0048] Such as figure 1 As shown, figure 1 It is a structural block diagram of the industrial exhaust gas liquefaction energy storage system provided in Embodiment 1 of the present invention.

[0049] In this embodiment, an industrial tail gas liquefaction energy storage power generation system includes a tail gas purification heat storage unit, a tail gas turbine power generation unit, a liquefaction separation storage unit, and a supercharged gasification power generation unit.

[0050] The exhaust gas purification and heat storage unit includes a hot water tank, a cold water tank, a first condensation purifier, a second condensation purifier, a first compressor, and a second compressor. The industrial exhaust gas enters the first condensation purifier to perform processing on the industrial exhaust gas. The first condensing purification treatment such as cooling, water vapor condensation and solid-phase soot precipitation, the first compressor pressurizes the industrial exhaust g...

Embodiment 2

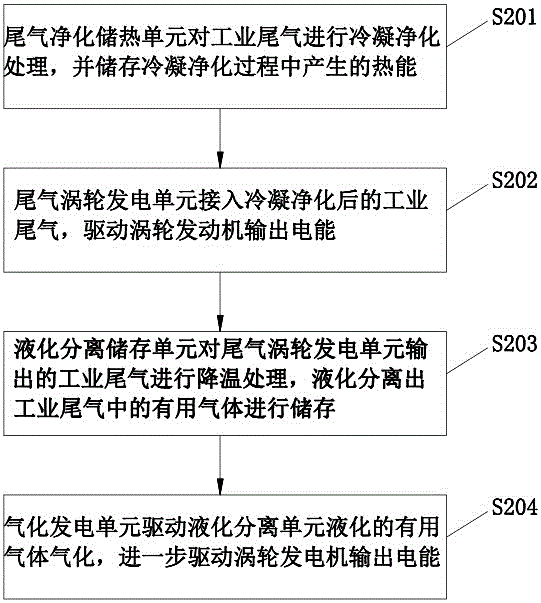

[0058] Such as figure 2 As shown, figure 2 It is a flow chart of the method for power generation by liquefaction of industrial tail gas provided in Embodiment 2 of the present invention.

[0059] In this embodiment, the method for power generation using the industrial tail gas liquefaction energy storage power generation system described in the first embodiment includes the following steps:

[0060] S201. The exhaust gas purification heat storage unit condenses and purifies the industrial exhaust gas, and stores the heat energy generated in the condensation purification process.

[0061] The first condenser performs the first condensation purification treatment of the incoming industrial exhaust gas, such as cooling, water vapor condensation and solid-phase soot deposition. The first compressor mixes and pressurizes the industrial exhaust gas and air after the first condensation purification treatment. The second condensing processor performs the second condensation purification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com