An annular airbag formwork for gob-side entry retaining concrete filling wall

A technology of annular airbags and filling walls, which is applied in the direction of fillings, earthwork drilling, safety devices, etc., which can solve the problems of difficult filling and reinforcement of supporting walls, rapid and continuous operations, affecting the final setting strength of concrete, and high labor intensity of workers and other problems, to achieve the effect of continuous fast filling operation, saving process connection time, and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below.

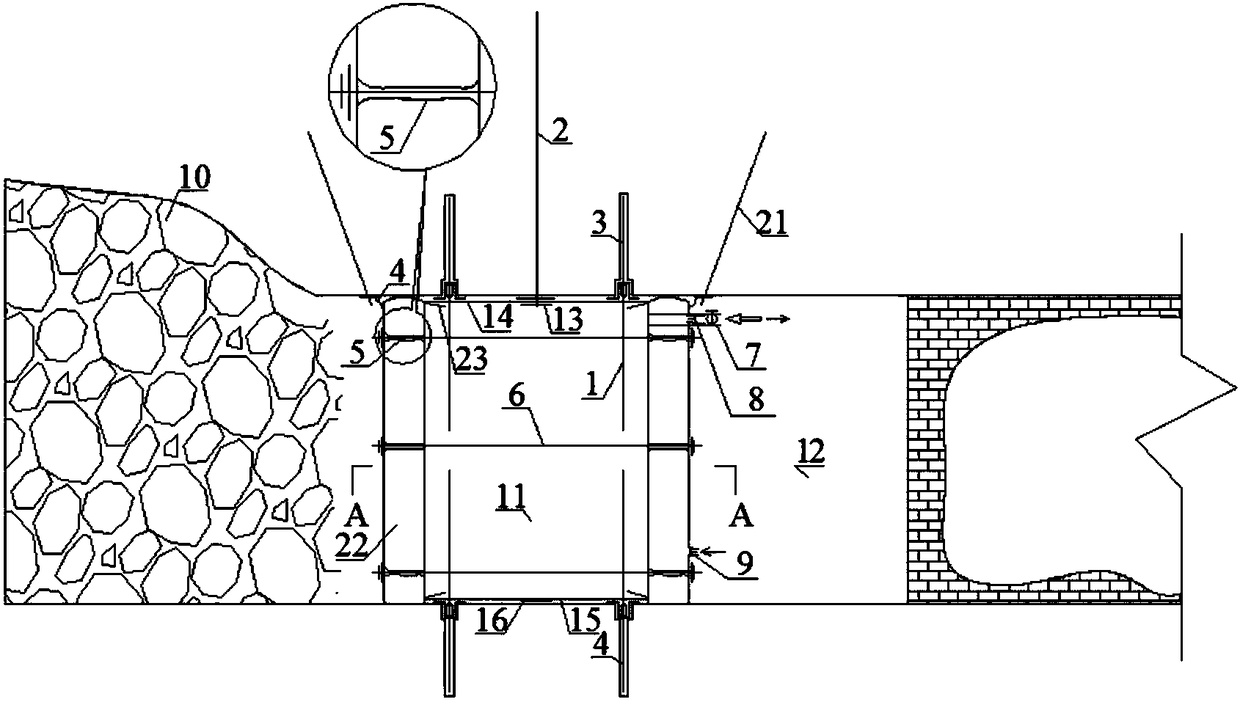

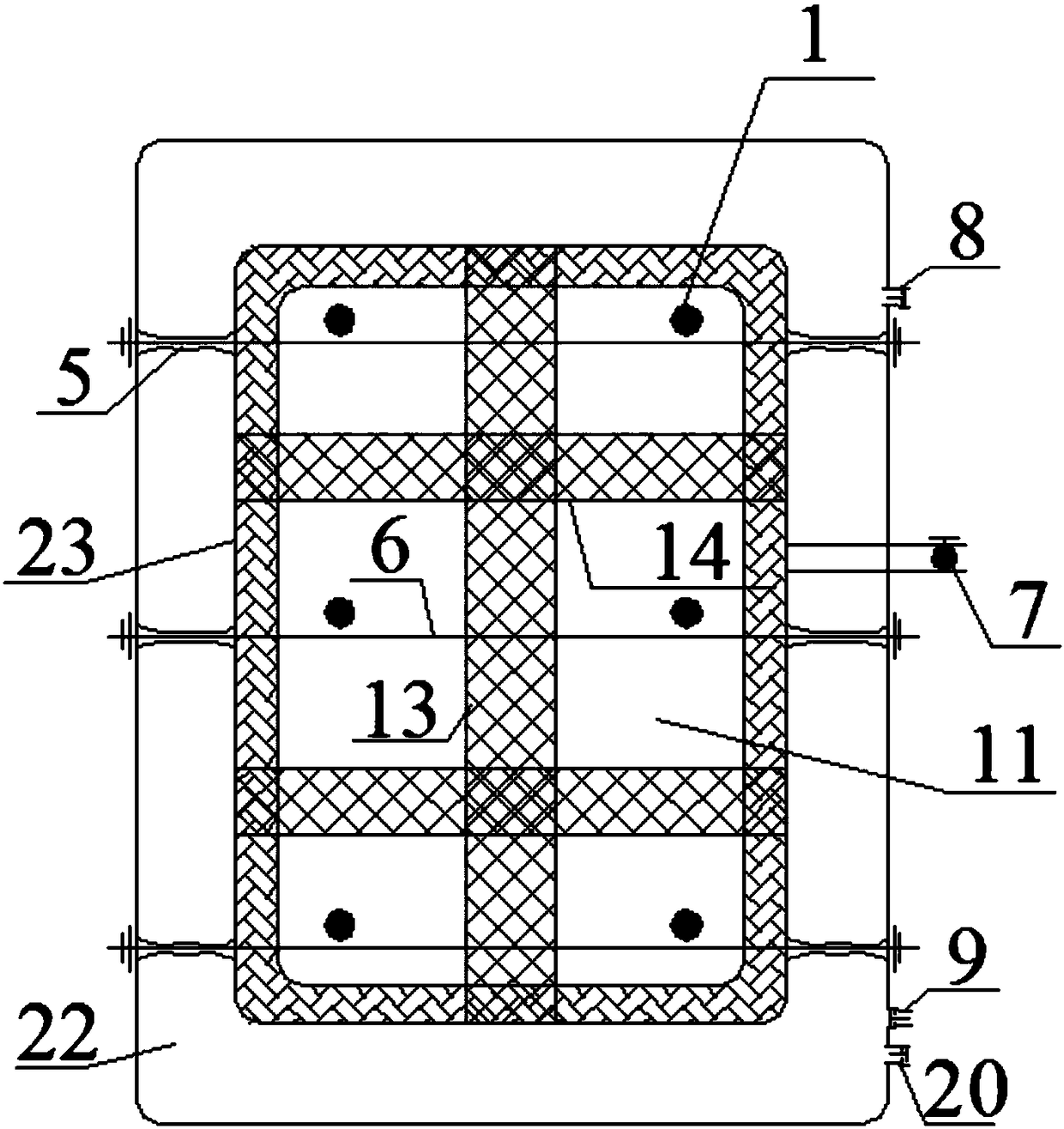

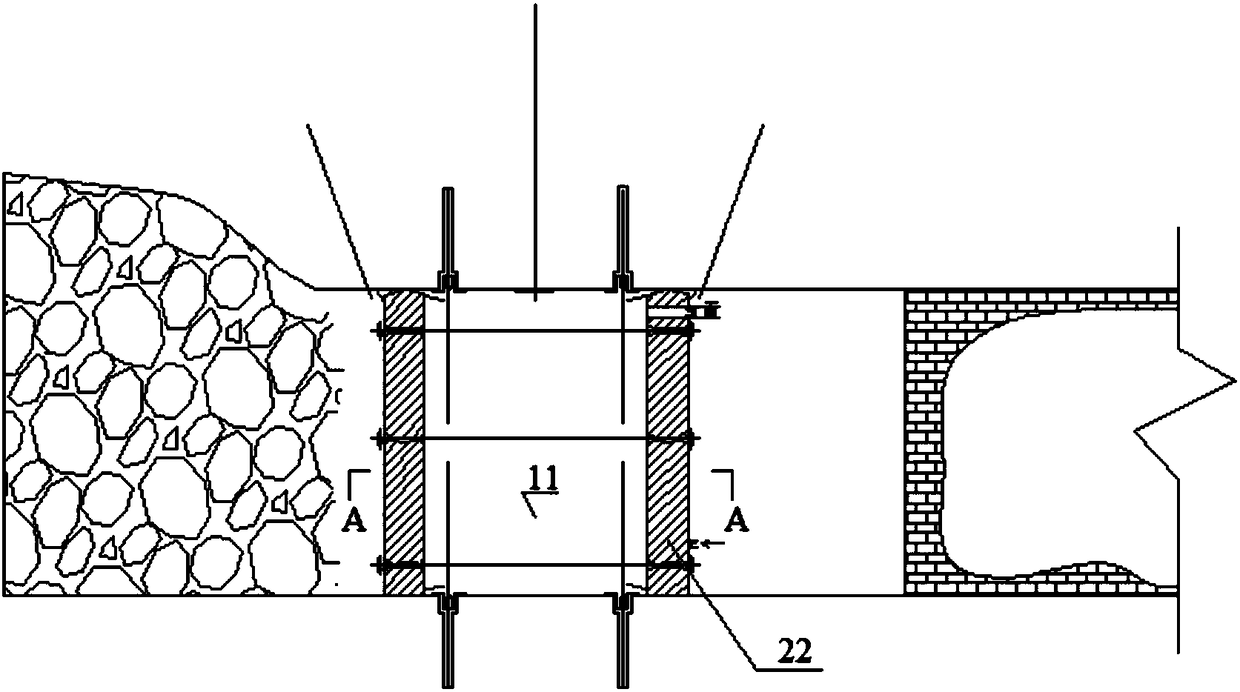

[0026] like Figure 1 to Figure 14 As shown, the present invention includes an annular air bag pressure bag 22 and a one-way concrete filling valve 7, the annular air bag pressure bag 22 is a closed structure surrounding a filling cavity 11; the one-way concrete filling valve 7 passes through the annular air bag pressure One side of the bag 22 is connected to the filling cavity 11 through, the annular air bag pressure bag 22 is provided with a one-way valve inflation hole 9, an exhaust hole I8 and an exhaust hole II 20, and the annular air bag pressure bag 22 is provided with a horizontal side limit anchor rod In the prefabricated hole 5, the top of the filling cavity 11 is provided with a top longitudinal reinforced strip 13 and a top transverse reinforced strip 14, and the bottom of the filling cavity 11 is provided with a bottom transverse reinforced strip 15 and a bottom longitudinal reinforced strip 16.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com