Electric rake-blasting force cooperative carrying false-inclined room-and-pillar method

A mining method and electric rake technology, which is applied in the field of electric rake-explosive force coordinated handling pseudo-inclined room-and-pillar mining method, can solve the problem of high equipment requirements, sloping thin ore bodies that cannot self-slip due to ore, ore bodies difficult to ore bodies, etc. problems, to achieve the effect of expanding the scope of application, improving the ore recovery rate, and reducing the amount of excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

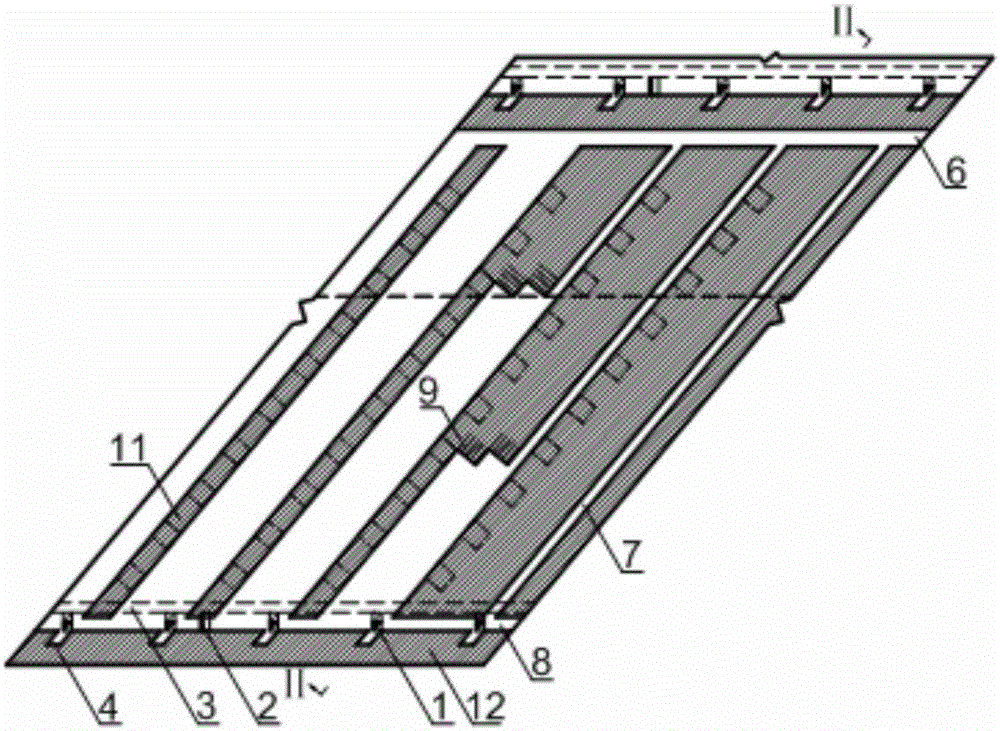

[0035] refer to figure 1 , the present embodiment carries out back mining aiming at the moderately stable ore body of the ore body roof, comprising the following steps:

[0036] (1) Divide the inclined thin ore body into stages. In the stage, the mining area is divided along the strike, with a length of 80m. Interval columns are reserved in the mining area. The ore blocks are arranged in the mining area. 90m in length, 15m in strike length, and 1-3m in height. The ore block is divided into ore rooms and ore pillars. The ore pillars are reserved for strip-shaped ore pillars 11 with a width of 5-7m, and the ore block is the basic mining unit;

[0037] (2) Since the specification is 2.5×2.5m 2 Stage 3 excavation of transport roadway 2×2m 2 Pedestrian patio 1, excavated 2×2m to the side of each mine 2 ore-drawing chute 2; excavate 2×2m from the pedestrian patio 1 at the lower boundary of the mine 2 The cutting level entry 8, which is also called the bottom entryway, is not onl...

Embodiment 2

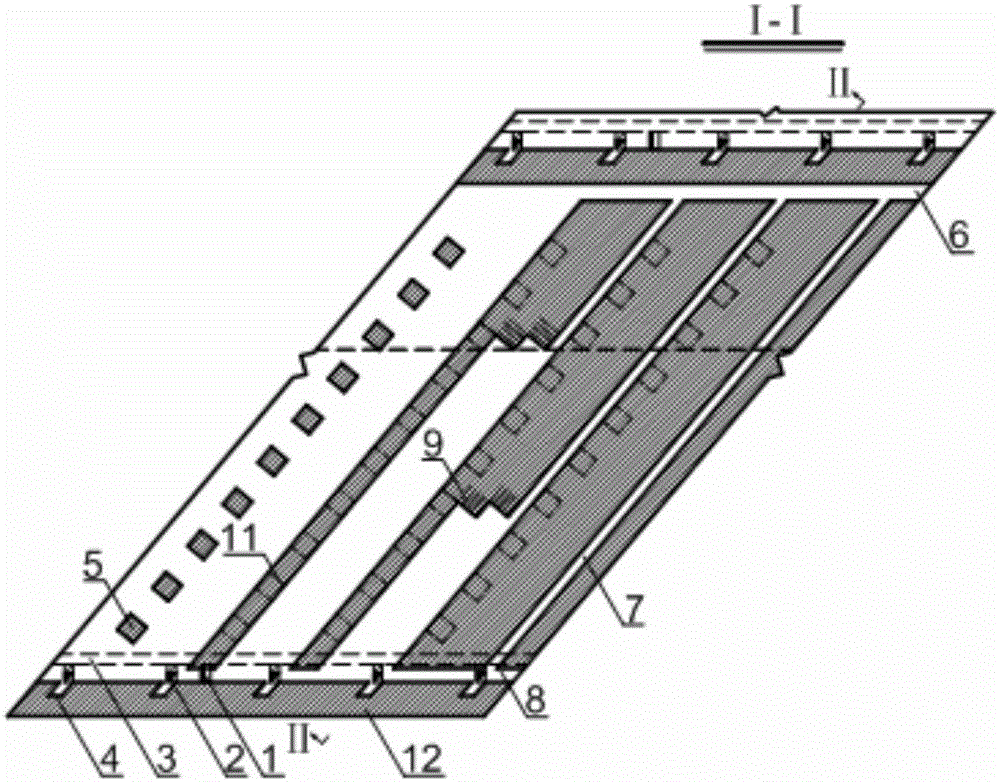

[0042] refer to figure 2 , this embodiment carries out back mining for the ore body that ore body roof is solid, comprises the following steps:

[0043](1) Divide the inclined thin ore body into stages, and divide the mining area along the strike in the stage, with a length of 100m. Space columns are reserved in the mining area, and the ore blocks are arranged in the mining area. 100m in length, 25m in strike length, and 1 to 3m in height. The ore block is divided into ore rooms and ore pillars. The ore pillars are reserved for strip-shaped ore pillars 11 with a width of 3 to 5m, and the ore block is the basic mining unit;

[0044] (2) Since the specification is 2.5×2.5m 2 Stage 3 excavation of transport roadway 2×2m 2 Pedestrian patio 1, excavated 2×2m to the side of each mine 2 ore-drawing chute 2; excavate 2×2m from the pedestrian patio 1 at the lower boundary of the mine 2 The cutting headway 8 is not only used as the free surface of the initial mining, but also as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com