Anti-deformation solid wood composite board and processing method thereof

A processing method and anti-deformation technology, applied in the field of flooring and wood products, can solve the problems of cumbersome processing process, air pollution, easy to produce deformation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

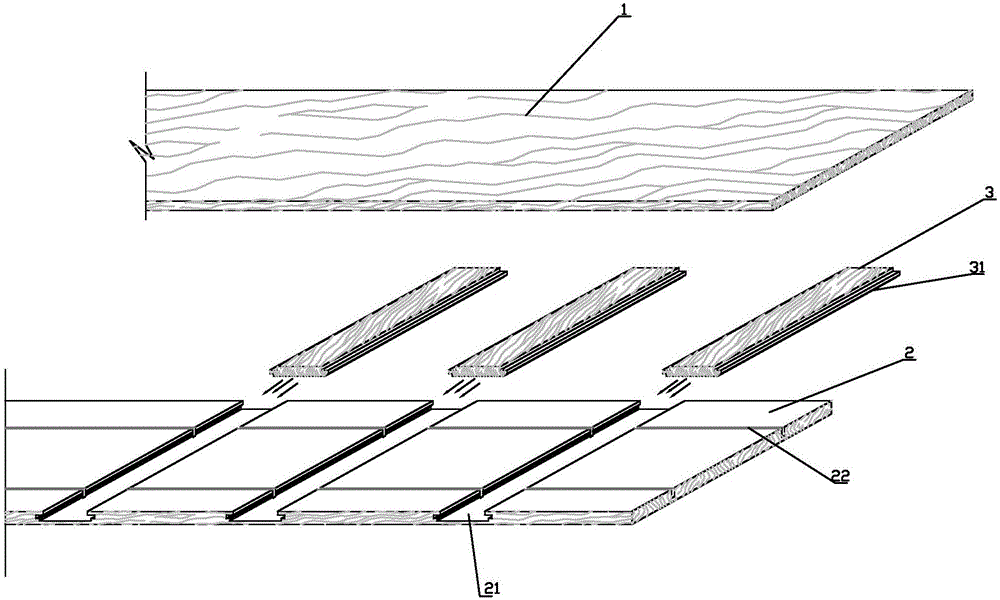

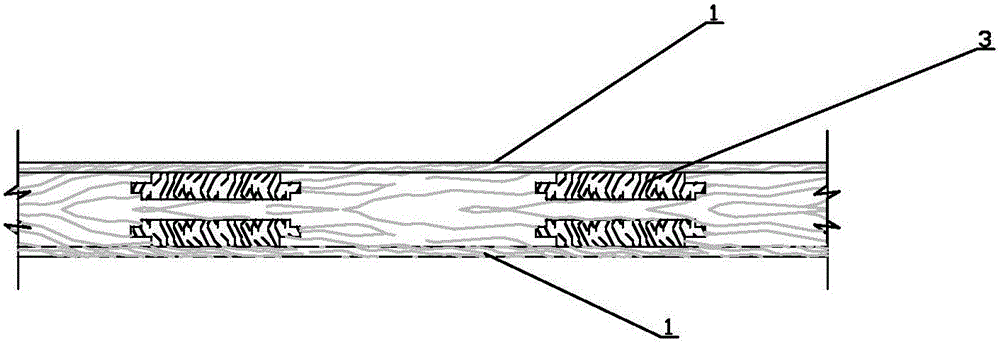

[0022] Such as Figure 1-Figure 2 As shown, the anti-deformation solid wood composite board of the present invention includes a solid wood base 2 (main board) and a surface layer 1 positioned on the solid wood base 2. In order to make the present invention difficult to deform during use, the solid wood base 2 is embedded with A plurality of horizontal tenons 3 are arranged at intervals along the width direction, and both sides of each horizontal tenon 3 are provided with outwardly protruding balance tenon edges 31, and the solid wood base layer 2 is correspondingly provided with a plurality of horizontal tenon 3 Cooperate with the mortise 21 of the device, the inner bottom surface of the mortise 21 is separated from the lower surface of the solid wood base 2 by a certain distance, and the upper surface of the horizontal tenon 3 and the upper surface of the solid wood base 2 are on the same plane. In the process of using the present invention, because the tenon groove cuts off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com