Continuous beam structure provided with V-shaped webs and construction method of continuous beam structure

A continuous web and beam structure technology, applied to bridges, bridge construction, bridge parts, etc., can solve the problems of bridge structure stiffness and strength reduction, long construction period, and accelerated steel corrosion, so as to improve the durability index and put into construction Low cost and the effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

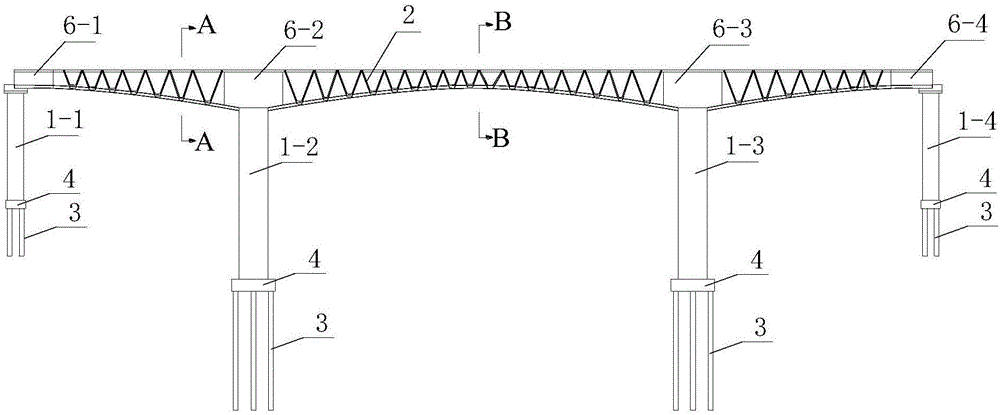

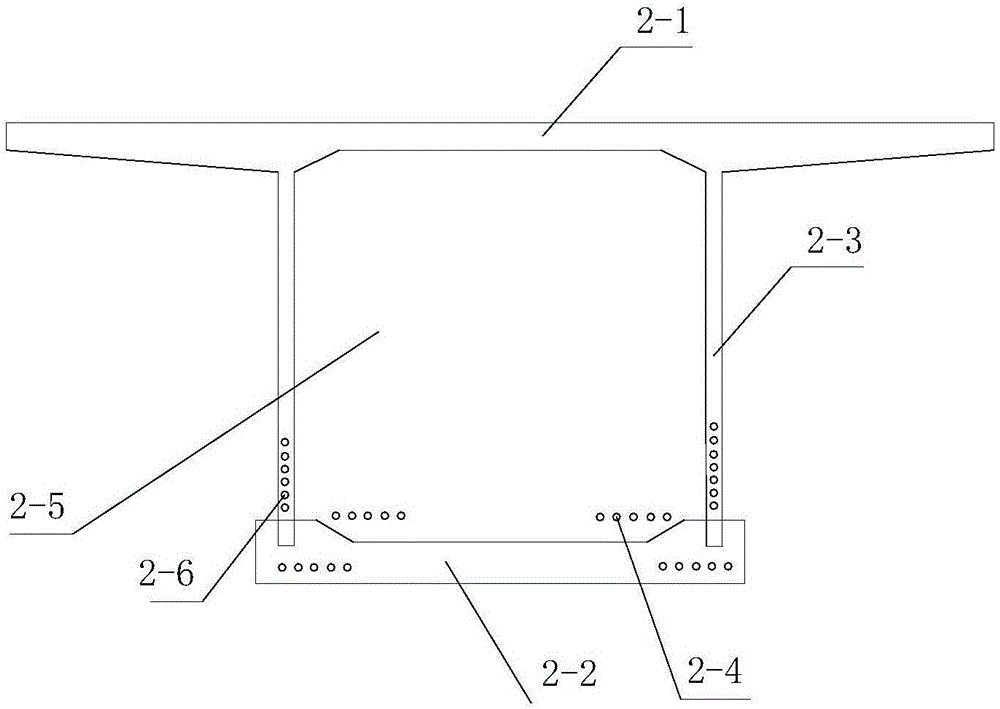

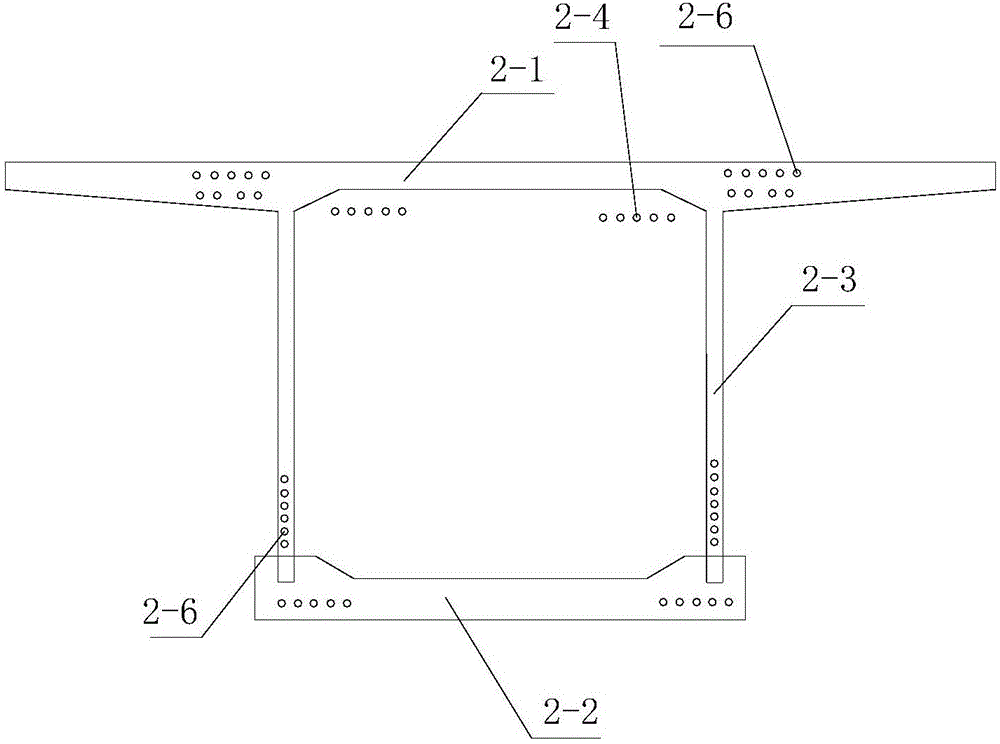

[0053] Such as figure 1 , figure 2 and image 3 A V-shaped web continuous girder structure shown includes a bridge lower support system and a composite box girder 2 erected on the bridge lower support system, and the composite box girder 2 includes a roof 2-1, a 1 bottom plate 2-2 and two left and right V-shaped webs 2-3 symmetrically connected between the top plate 2-1 and the bottom plate 2-2; the top plate 2-1 and the bottom plate 2-2 are made of high-strength concrete A poured concrete slab, the V-shaped web 2-3 is composed of a plurality of V-shaped prefabricated slabs arranged along the longitudinal bridge direction, and the plurality of V-shaped prefabricated slabs are arranged along the longitudinal bridge direction from front to back , the V-shaped prefabricated slab is a concrete prefabricated slab cast from ultra-high performance concrete.

[0054] In this embodiment, both the top plate 2-1 and the bottom plate 2-2 are cast-in-place concrete plates made of high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com