Plant composite fiber, plant fiber composite and preparation method of plant fiber composite

A composite fiber and plant fiber technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of poor plasticity, indoor air pollution, and low plant fiber content, and achieve high strength, stable bonding, and air permeability of the finished product Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A plant composite fiber, the plant composite fiber is mainly mixed with plant fiber and low-melting point polyester fiber, the weight ratio of the plant fiber and low-melting point polyester fiber is 5:1, and then it is produced by spunlace or needle punching process , wherein the melting point of the low melting point polyester fiber is 80°C.

Embodiment 2

[0051] A plant composite fiber, the plant composite fiber is mainly mixed with plant fiber and low-melting point polyester fiber, the weight ratio of the plant fiber and low-melting point polyester fiber is 1:1, and then it is produced by spunlace or needle punching process , wherein the melting point of the low melting point polyester fiber is 200°C.

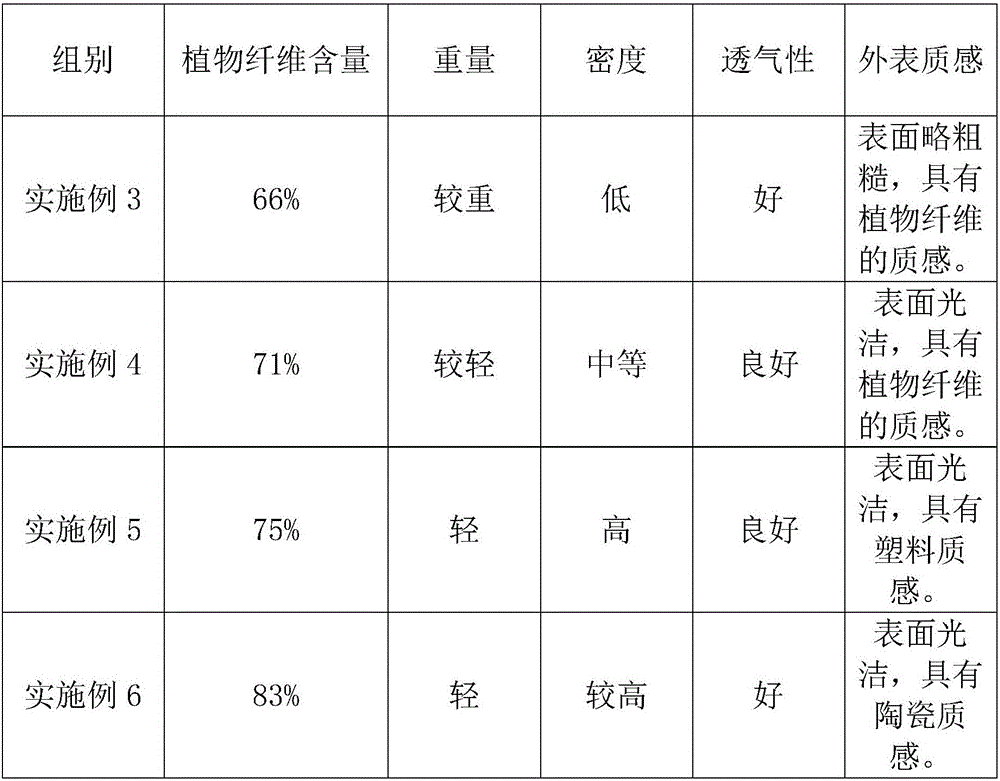

Embodiment 3

[0052] Example 3 Preparation of Mattress

[0053] A plant composite fiber, the plant composite fiber is mainly mixed with plant fiber and low-melting point polyester fiber, the weight ratio of the plant fiber and low-melting point polyester fiber is 2:1, and then it is made by hydroentanglement or needle punching process , wherein, the melting point of the low melting point polyester fiber is 150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com