Method for prolonging catalyst use period in hydrocarbon polymerization aromatization technique

A technology for prolonging catalysts and aromatization, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oils. It can solve problems such as poisoning and deactivation, aggravated catalyst carbon deposition, and decreased olefin conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] before improvement

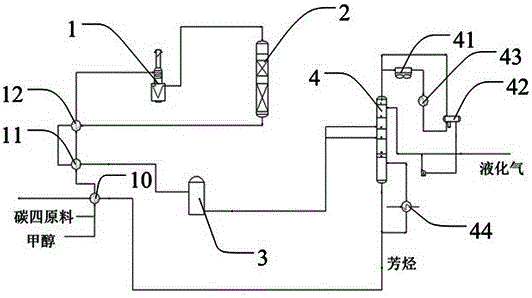

[0018] After the C4 raw material is preheated by the preheater, it enters the first feed heat exchanger and the second feed heat exchanger to exchange heat with the reaction product from the stacked reactor, and the mixed raw material after heat exchange is heated The furnace is further raised to 350°C-480°C and then enters the stacked reactor. The pressure of the stacked reactor is controlled at 1.05-1.6MPa, and the reaction is carried out under the action of OIL-1 catalyst (purchased from Shanghai Petrochemical); The bottom of the combined reactor enters into the second feed heat exchanger, the first feed heat exchanger and the mixed raw material for heat exchange, and then enters the stabilizing tower. The pressure of the stabilizing tower is controlled at 0.6-1.5MPa, and the bottom temperature is controlled at 105 -185°C, the product is divided into aromatics and liquefied gas under the action of the rectification of the stabilizing tower; the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com