Compound modifier for widening using temperature range of bituminous mixture and preparation method thereof

A compound modifier and asphalt mixture technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of asphalt pavement cracks, rutting, wave movement, affecting the durability and service life of the pavement, and achieve consumption saving , good environmental protection, and the effect of widening the operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Preparation of activated rubber powder: Mix 30Kg of dried waste rubber powder (dried in a constant temperature drying oven at 60°C, the drying time is not less than 6 hours, and the particle size is 40 mesh) with 15Kg of 5# diesel oil. Seal and place for 72 hours to obtain activated rubber powder.

[0018] Preparation of grafted modified eucommia gum: Add 2Kg eucommia gum to an internal mixer, masticate at 110°C for 10 minutes at a speed of 100rad / min, then add the masticated eucommia gum to 10Kg xylene, and heat up to 70 Stir at ℃ at the same time to fully dissolve Eucommia gum in xylene, then add 300g of maleic anhydride monomer and 30g of dibenzoyl peroxide, continue to stir and react for 4h. and placed in a vacuum oven at 60°C to dry to constant weight to obtain grafted modified Eucommia gum.

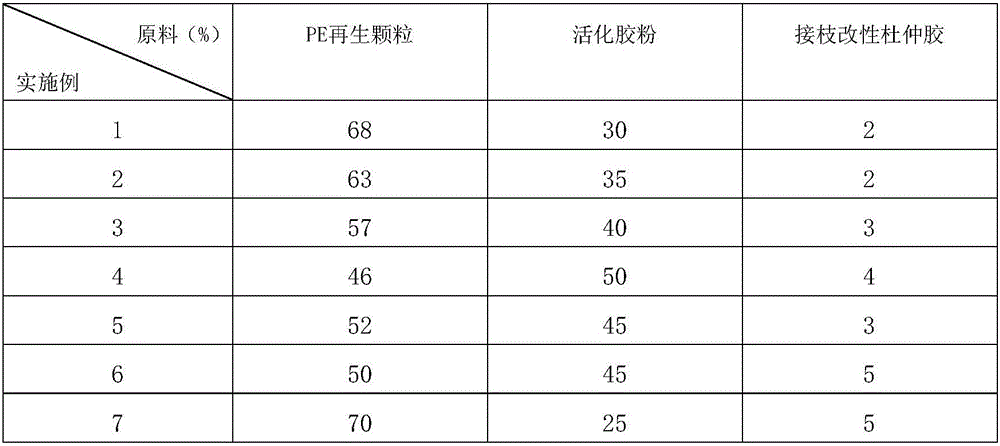

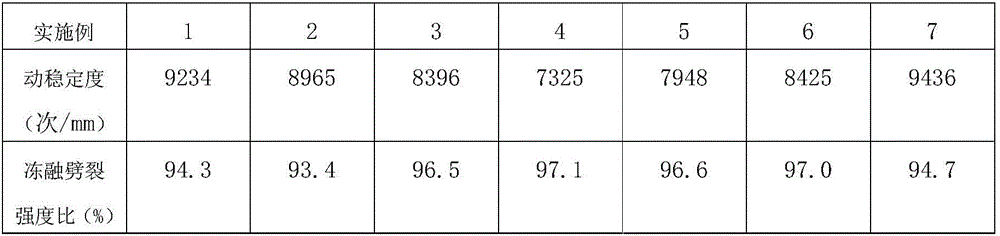

[0019] Prepare a compound modifier for widening the temperature range of asphalt mixture: 68Kg PE regenerated granules, 30Kg activated rubber powder, and 2Kg grafted modifie...

Embodiment 2

[0021] Preparation of activated rubber powder: Mix 35Kg of dried waste rubber powder (dried in a constant temperature drying oven at 60°C, the drying time is not less than 6 hours, and the particle size is 40 mesh) with 17.5Kg of 97# gasoline. The lower seal was placed for 72 hours to obtain activated rubber powder.

[0022] Preparation of grafted modified eucommia gum: Add 2Kg eucommia gum to an internal mixer, masticate at 110°C for 10 minutes at a speed of 100rad / min, then add the masticated eucommia gum to 10Kg xylene, and heat up to 80 Stir at the same time at ℃ to fully dissolve Eucommia gum in xylene, then add 200g of maleic anhydride monomer and 20g of dibenzoyl peroxide, continue to stir and react for 4h. and placed in a vacuum oven at 60°C to dry to constant weight to obtain grafted modified Eucommia gum.

[0023] Prepare a compound modifier for widening the temperature range of asphalt mixture: 63Kg PE regenerated granules, 35Kg activated rubber powder, and 2Kg gra...

Embodiment 3

[0025] Preparation of activated rubber powder: Mix 40Kg of dried waste rubber powder (dried in a constant temperature drying oven at 60°C, the drying time is not less than 6 hours, and the particle size is 40 mesh) with 20Kg of 97# gasoline, and after mixing evenly, put it at room temperature Seal and place for 48 hours to obtain activated rubber powder.

[0026] Preparation of grafted modified eucommia gum: Add 3Kg eucommia gum to an internal mixer, masticate at 110°C for 10 minutes at a speed of 100rad / min, then add the masticated eucommia gum to 15Kg xylene, and heat up to 70 Stir at the same time at ℃ to make Eucommia gum fully dissolve in xylene, then add 300g maleic anhydride monomer and 30g dicumyl peroxide, continue to stir and react for 5h, use acetone to precipitate and separate the product after the reaction, and then wash with distilled water for 3 and placed in a vacuum oven at 60°C to dry to constant weight to obtain grafted modified Eucommia gum.

[0027] Prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com