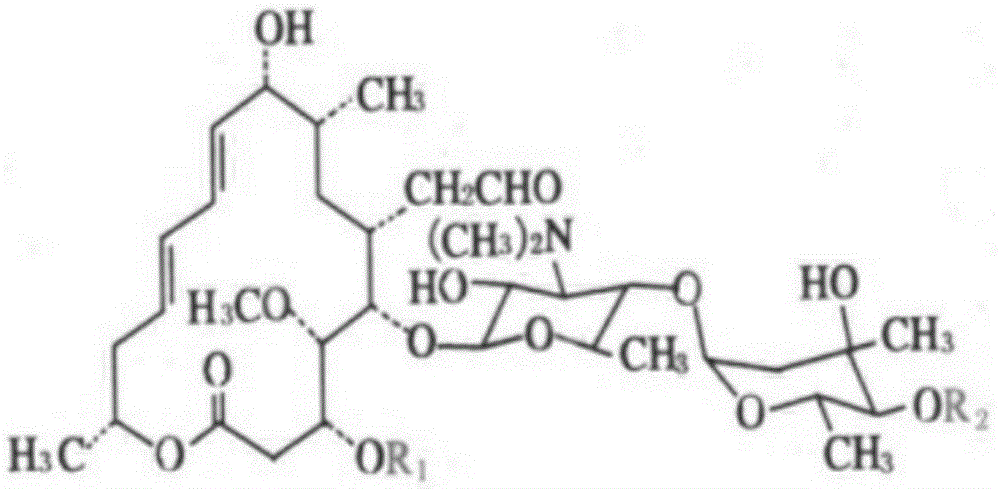

Clean kitasamycin extraction process

A kitamycin extraction technology, applied in the field of clean extraction technology of kitamycin, can solve the problems of high cost of harmless treatment, difficult treatment, large pH fluctuations, etc., and achieve significant environmental protection and production benefits, and is very practical Sexuality and popularization and application value, and the effect of reducing the proportion of wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The clean extraction process of gemitamycin provided by the application specifically includes the following steps:

[0032] (1) Acidify the fermentation broth

[0033] Specifically, adding saturated oxalic acid aqueous solution to the fermented liquid containing gemitamycin obtained after microbial fermentation, and adjusting its pH to 3.5.

[0034] (2) filter

[0035] In this embodiment, the fermented liquid after acidification in step (1) is obtained by suction filtration to obtain the filtrate, that is, the raw liquid to be extracted containing gemitamycin;

[0036] In order to determine better experimental parameters, for the obtained filter residue (filter cake, that is, the insoluble solid substance after filtration of the fermentation broth), clean water and raffinate (that is, heavy liquid, the adopted The heavy liquid is the heavy liquid prepared according to the prior art after adopting the above steps (1) and (2) and is washed three times, and the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com