Method for purifying compound

A compound and mixed solution technology, applied in the direction of organic chemistry, can solve the problems of reducing equipment production efficiency, safety hazards, and increasing production costs, and achieve the effects of easy control, improved production efficiency, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

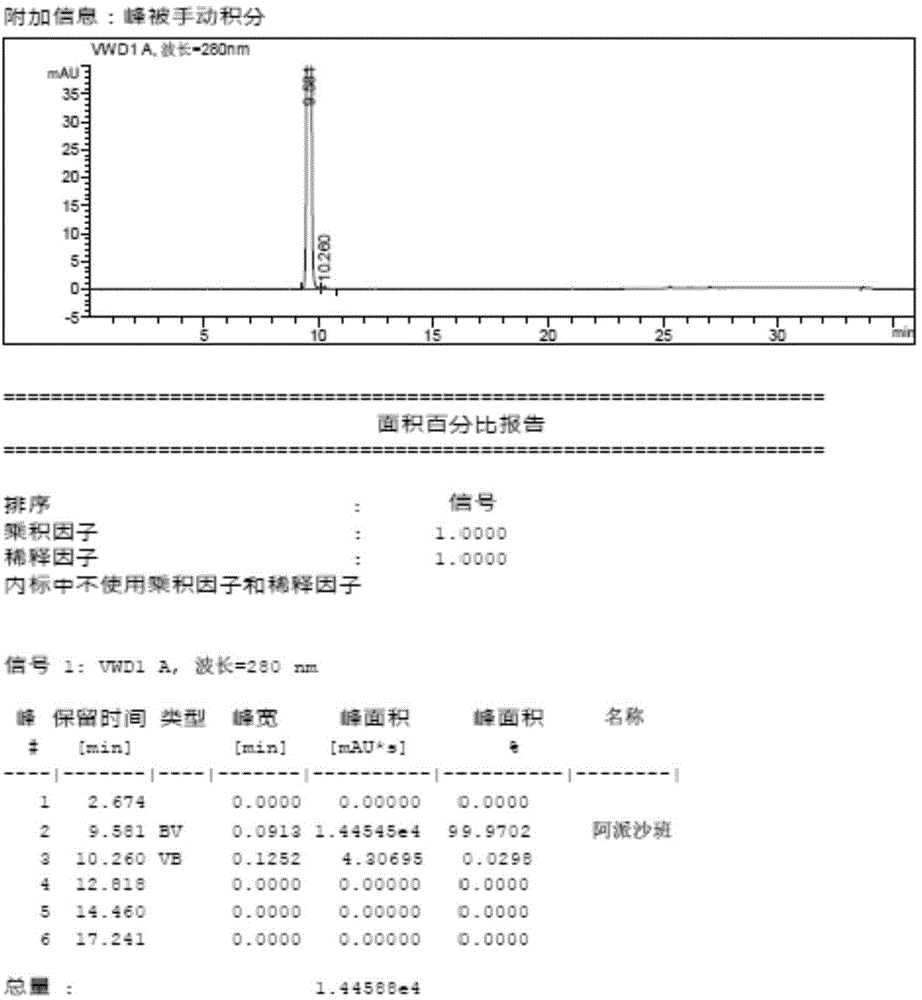

Embodiment 1

[0069] Take a 250ml one-mouth bottle, add 10g of crude apixaban (95.4% purity) and 80ml of ethylene glycol solution containing 10% ammonia, heat to 90°C to dissolve, then add 80ml of water to cool down at 40-50°C and stir for 2 hours , cooled to 0 ~ 10 ℃. Then it was filtered and dried to obtain 8.9 g of off-white solid with a yield of 89% and a HPLC purity of 99.97%.

[0070] Spectral data:

[0071] EI-MS (m / z): 460.2;

[0072] 1 H-NMR (500MHz, CDCl 3 , ppm), δ: 7.49(d, J=8.8Hz, 2H), 7.36(d, J=8.8Hz, 2H), 7.27(d, J=8.8Hz, 2H), 6.95(d, J=8.8Hz , 2H), 6.88(br, 1H), 5.59(br, 2H), 4.13(t, J=6.6Hz, 2H), 3.84(s, 3H), 3.61~3.60(m, 2H), 3.39(t, J=6.8Hz, 2H), 2.57(t, J=5.6Hz, 2H), 1.94~1.96(m, 4H).

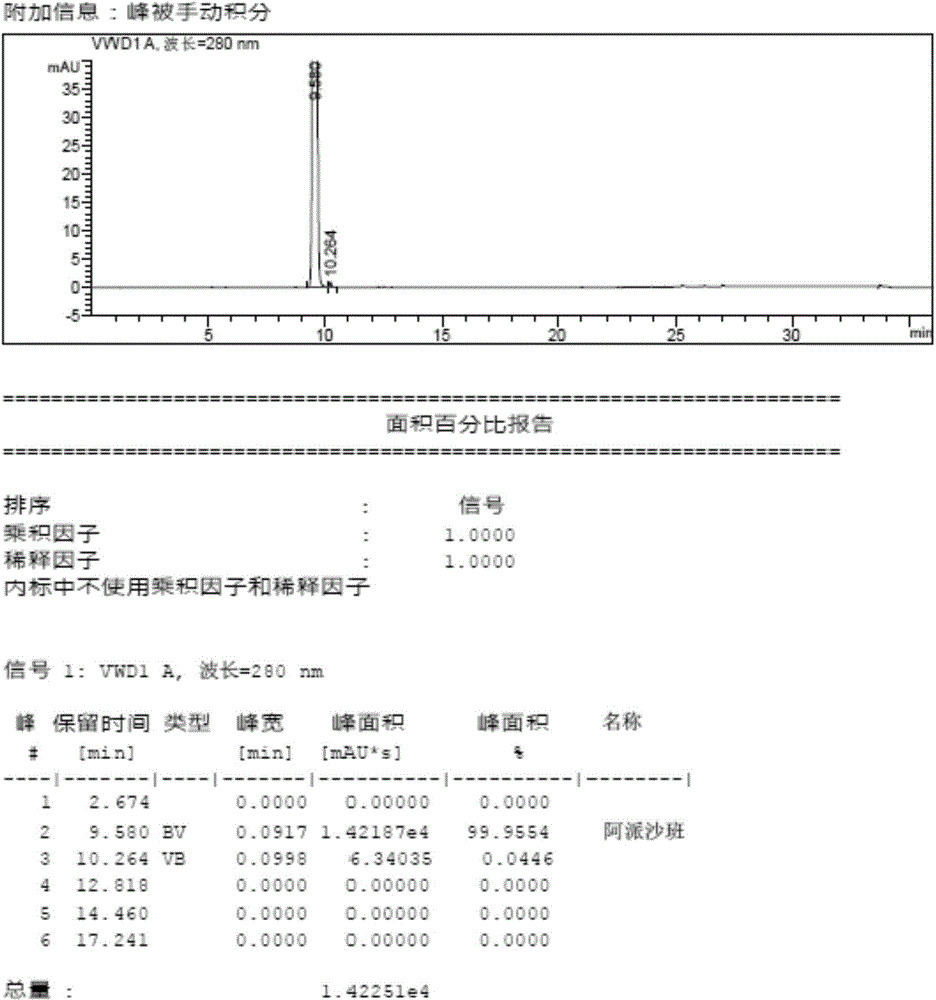

Embodiment 2

[0074] Take a 250ml single-necked bottle, add 10g of apixaban crude product (95.4% purity) and 160ml of ethylene glycol solution containing 5% triethylamine, heat to dissolve, then add 100ml of water to cool down and stir at 40-50°C for 2 Hours, cool down to 0-10°C. Then it was filtered and dried to obtain 8.5 g of off-white solid with a yield of 85% and a purity of 99.96% by HPLC.

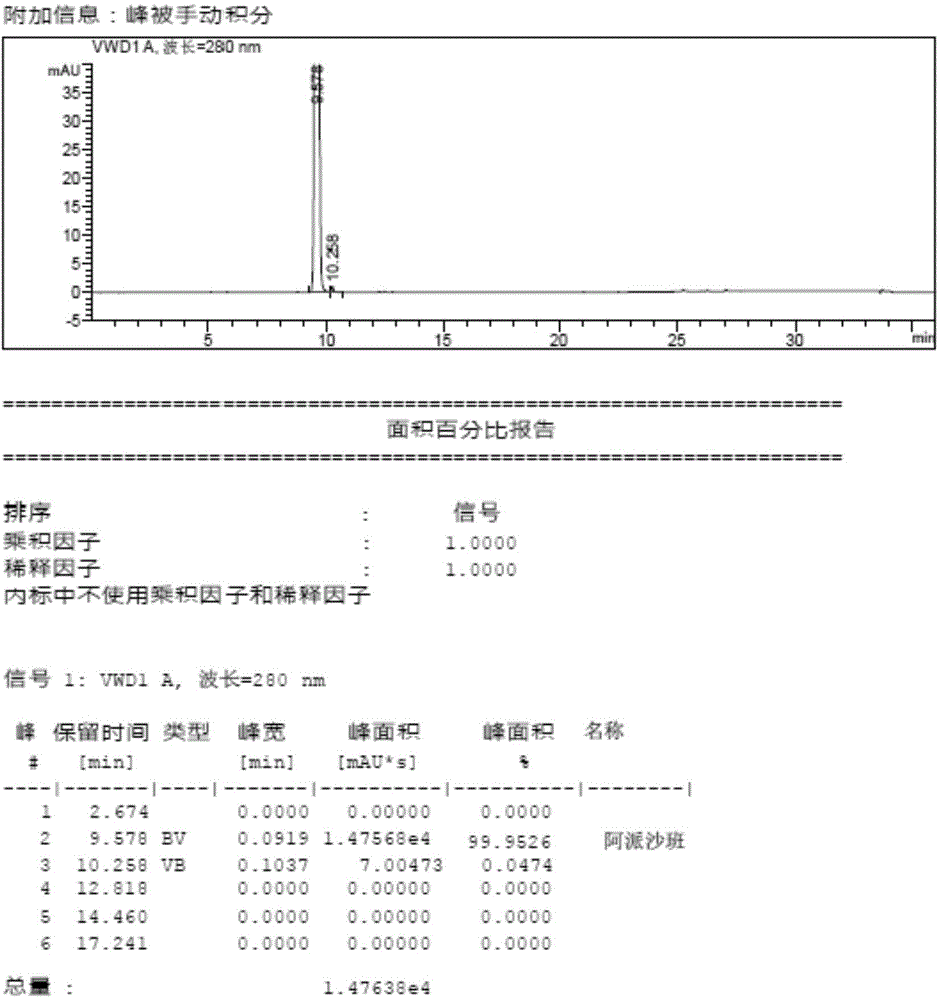

Embodiment 3

[0076] Take a 250ml single-necked bottle, add 10g of apixaban crude product (purity is 95.4%) and 100ml of methanol solution containing 20% ammonia, heat to dissolve, then add 40ml of water to cool down, stir at 40-50°C for 2 hours, cool to 0~10℃. Then it was filtered and dried to obtain 8.6 g of off-white solid with a yield of 86% and a purity of 99.95% by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com