A kind of strength controllable amphiphilic graphene airgel and its preparation method

A graphene airgel and graphene technology, applied in ceramic products, other household utensils, household utensils, etc., can solve the problems of phase separation, poor dispersion of cellulose nanocrystals, and materials without amphiphilic properties, and achieve time-consuming The effect of less, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

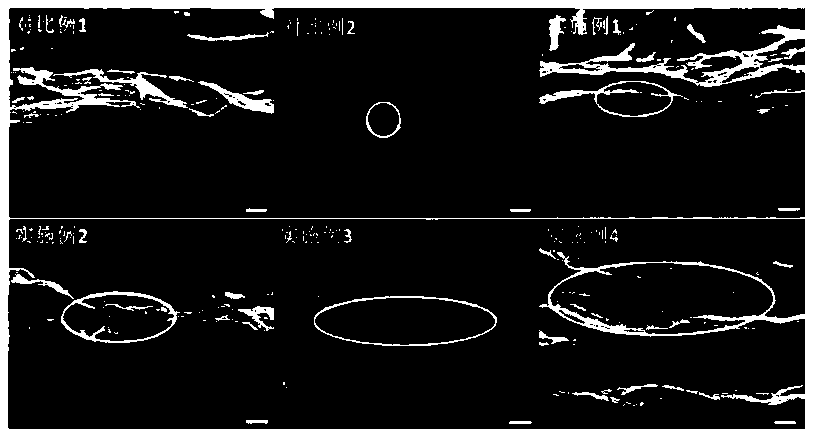

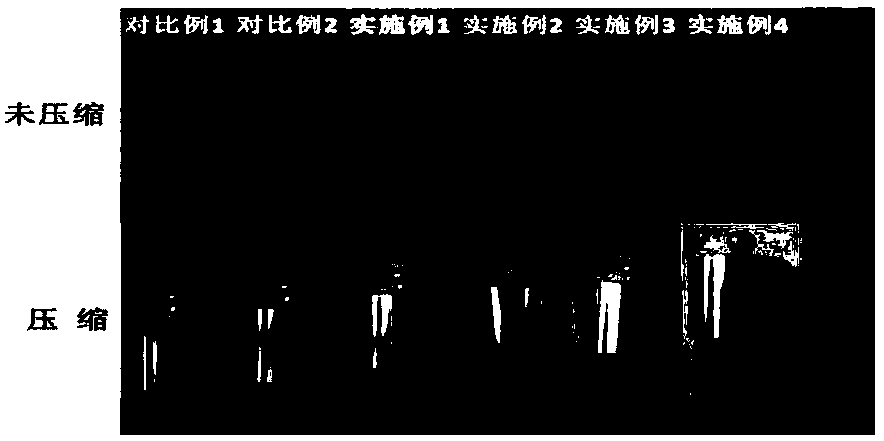

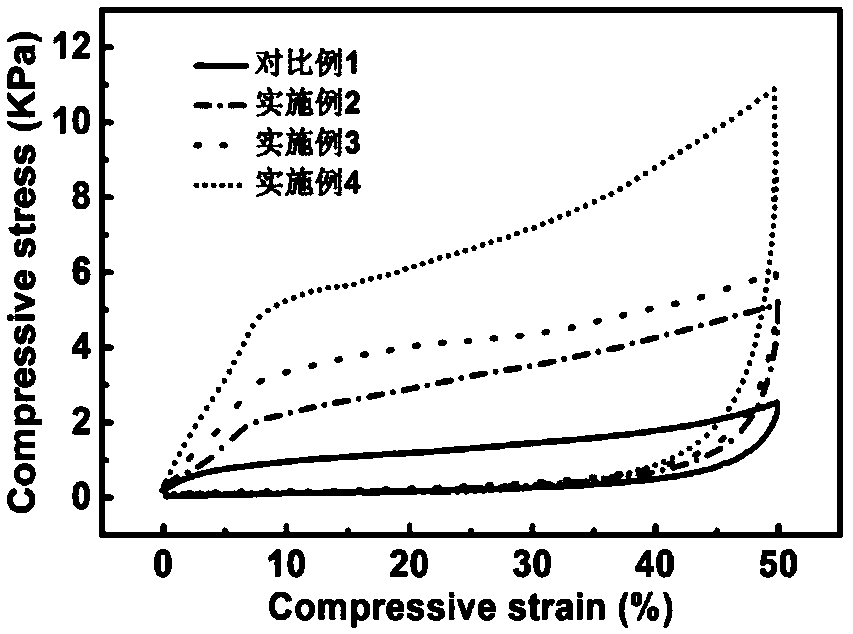

Embodiment 1

[0056] Prepare 5mg.ml -1 aqueous dispersion of graphene oxide. Get 6ml of the above graphene oxide water dispersion and place it in a cylindrical bottle, add 2ml of 0.79mg.ml -1 The aqueous dispersion of cellulose nanocrystals was added, and 60 mg of vitamin C was added to the mixed solution, and put into a blast drying oven at 80 degrees Celsius to react for 25 minutes. After taking it out and cooling to room temperature, put it in a refrigerator at -20 degrees Celsius for 3 hours, and then melt it at room temperature. After washing twice with deionized water, it was washed with alcohol, and then placed in a blast drying oven for 24 hours to obtain a hybrid graphene airgel with a cellulose nanocrystal content of 5%.

Embodiment 2

[0058] The type, consumption and technological process of the materials used are the same as in Example 1, except that the concentration of the cellulose nanocrystals used is 1.67mg.ml -1 . A hybrid graphene airgel with a cellulose nanocrystal content of 10% was prepared.

Embodiment 3

[0060] The type, consumption and technological process of the materials used are the same as in Example 1, except that the concentration of the cellulose nanocrystals used is 3.75mg.ml -1 . A hybrid graphene airgel with a cellulose nanocrystal content of 20% was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com