Rebound self-locking type insertion and extraction stop lever butt-joint mechanism

A docking mechanism and self-locking technology, applied in the field of a rebound self-locking plug-and-pull stopper docking mechanism, can solve the problems of low cargo transfer efficiency, low alignment accuracy, and high maintenance costs, and achieve simple structure and accurate alignment. The effect of improved efficiency and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

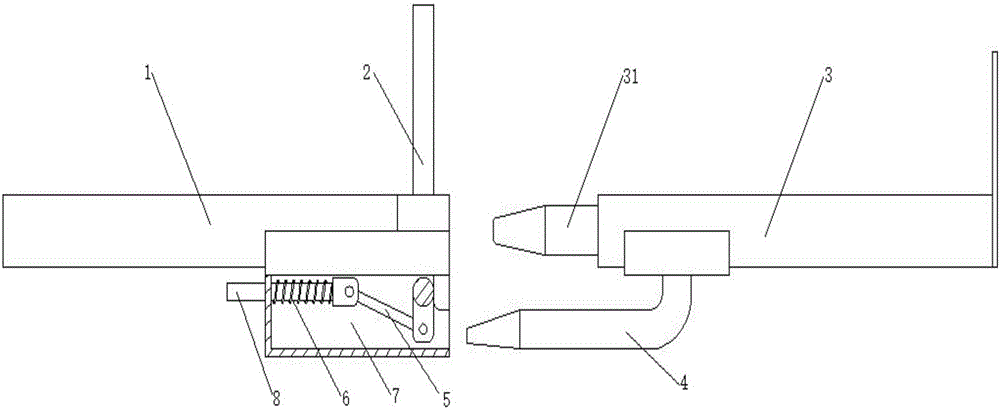

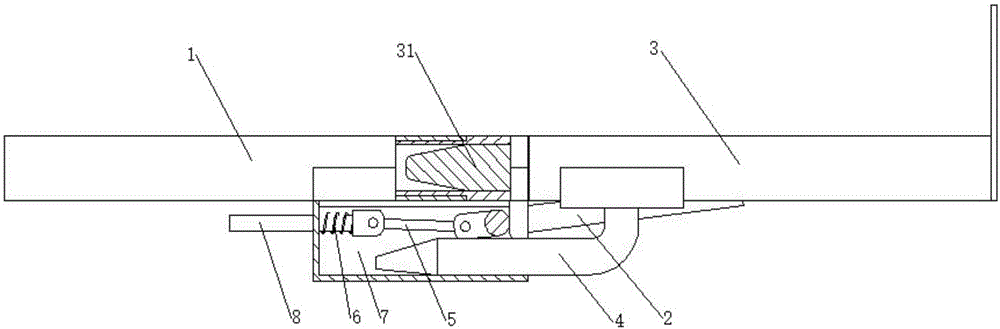

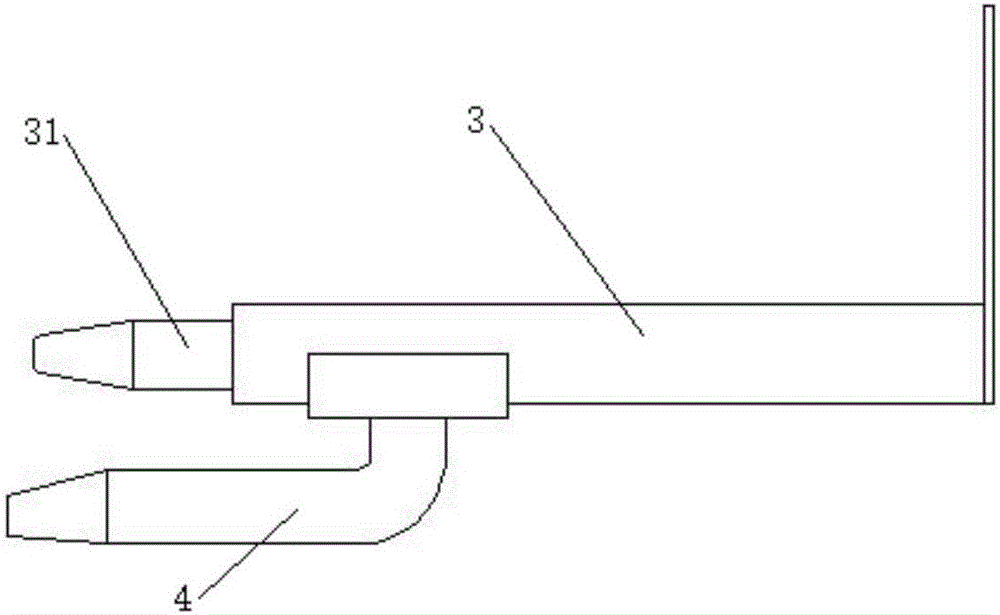

[0033] A rebound self-locking plug-in lever docking mechanism, such as figure 1 , figure 2 As shown, it includes a cargo support tube 1, an L-shaped stop rod 2, an insertion tube 3, an alignment insertion rod 4, a connecting rod 5, a telescopic spring 6, a housing 7 and a sliding rod 8, and the cargo support tube 1 is installed on a three-dimensional On the storage rack, the shell 7 is connected to the cargo support pipe 1, the long arm of the L-shaped blocking rod 2 is a freely rotating arm, the short arm is connected to the connecting rod 5, and one end of the connecting rod 5 is connected to the short arm of the L-shaped blocking rod 2, The other end is connected with the slide bar 8, the slide bar 8 is located in the housing 7, and one end passes through the housing 7, the head end of the slide bar 8 has a limit block for limiting the telescopic spring 6, the telescopic spring 6 is limited between the limit block of the slide rod 8 and the side wall of the housing 7, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com