Clamp tool table capable of rotating and displacing

A technology of tooling tables and fixtures, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of inconvenient production process, inconvenient fastening and positioning of tooling tables, and inability to provide movable actions, so as to reduce operation and processing Difficulty, the effect of facilitating the fastening and positioning of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

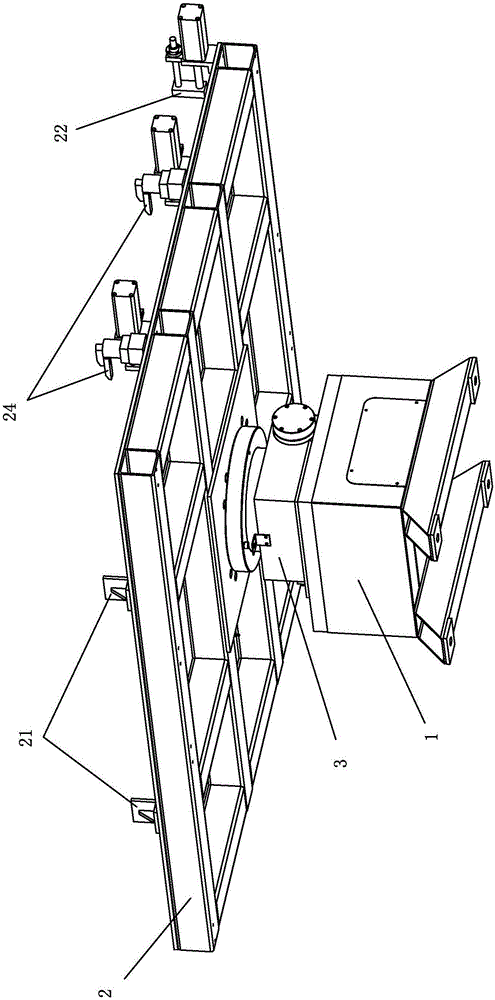

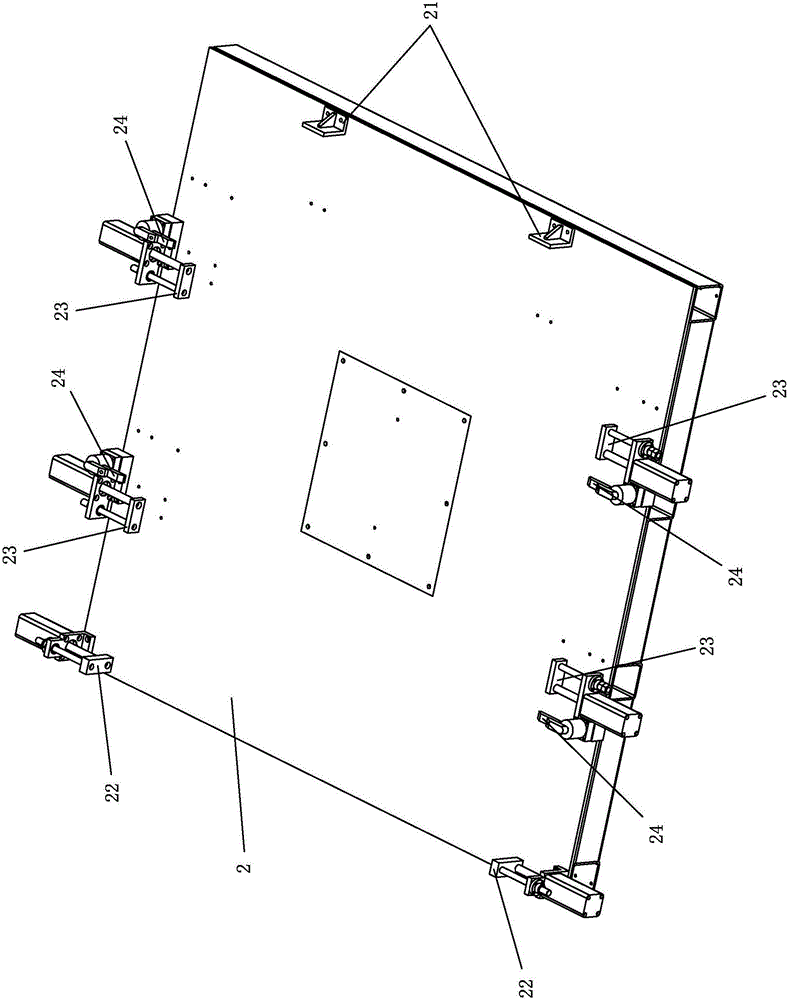

[0016] refer to figure 1 and figure 2 , a rotatable and displaceable fixture tooling platform of the present invention includes a base 1 and a machine platform 2, the machine platform 2 is mounted on the base 1 through a rotating seat 4, the main body of the rotating seat 3 and the base 1. Tightly connected, the rotating disk of the rotating seat 3 is connected with the bottom surface of the machine table 2. The rotating seat 3 is provided with a driving motor to drive its rotating disk through a transmission mechanism. The edges of the machine table 2 are respectively provided with positioning stops that limit the movement of the workpiece to achieve positioning. Plate 21, clamping movable baffle 22, top connecting movable baffle 23 and pressure plate 24, the positioning baffle 21 and clamping movable baffle 22 are respectively located on the lateral edges of the machine 2, and the top connecting movable The baffle plate 23 and the pressing plate 24 are respectively arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com