Wood veneer clip-type assembly component and its installation method

A wood veneer card type and installation method technology is applied in the field of wood veneer card type assembly components and installation to achieve the effects of reducing material costs, saving management costs, and reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

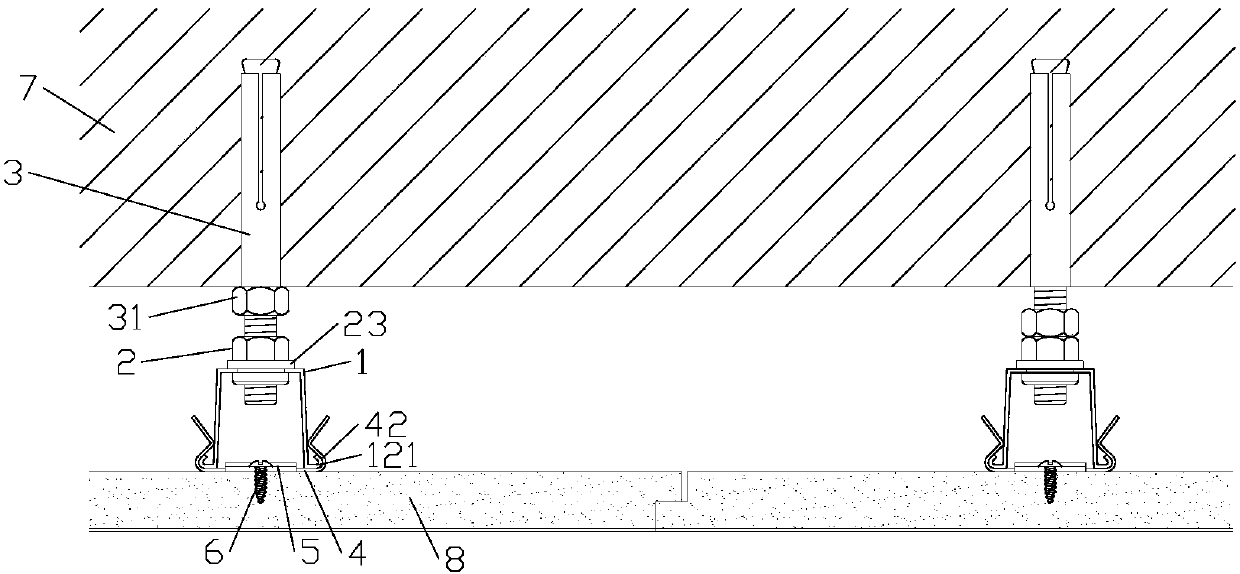

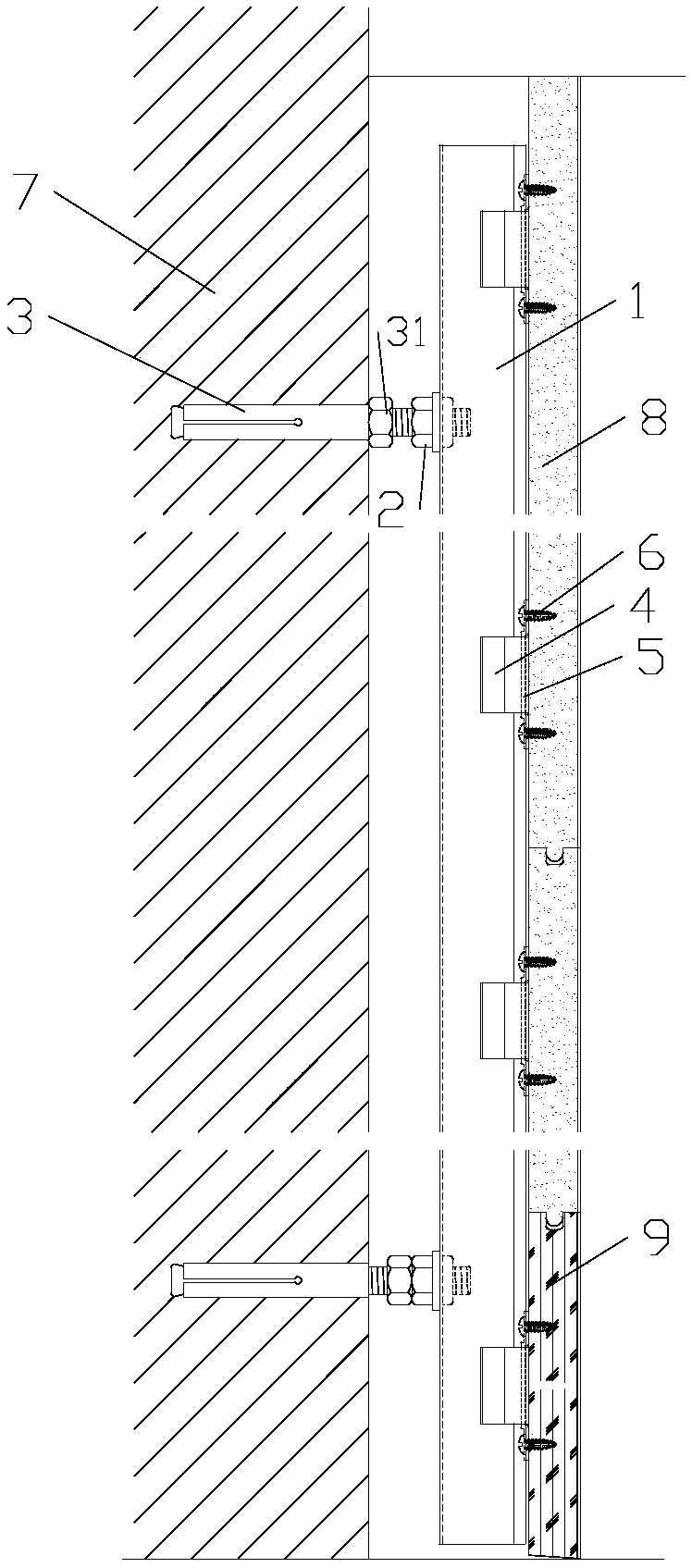

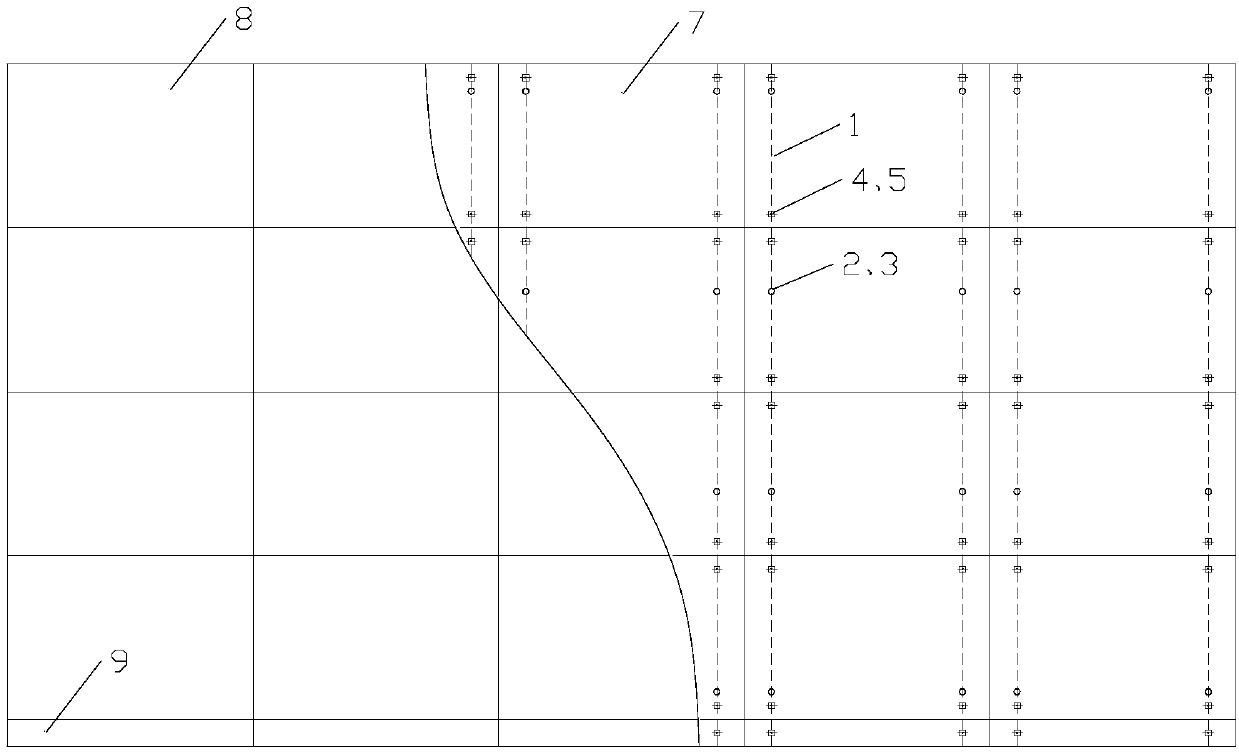

[0050] Such as Figure 1-9 As shown, the present invention provides a wood veneer clip assembly component, comprising:

[0051] A wood veneer clamp assembly component, comprising:

[0052] A plurality of keels 1, which are made of U-shaped galvanized light steel profiles, are vertically arranged, and the bottom surface 11 of any keel 1 is provided with a plurality of jacks 13, and the ends of the two sides 12 of any keel 1 respectively face The outer side is bent to form an arc-shaped corner 121;

[0053] A plurality of cage nuts 2, any cage nut 2 is provided with a first screw hole 21 inside, and an annular slot 22 is provided on the outside, and the cage nut 2 is inserted through the annular slot 22 and the keel 1. The hole 13 is clamped; so that when the cage nut is rotated, the keel can also move forward and backward with the advance and retreat of the cage nut, so as to achieve the purpose of adjusting the verticality and flatness of the keel and the wall; and,

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com