Lower die displacement type continuous thin plate stamping device

A sheet metal stamping and displacement technology, applied in the field of mechanical processing, can solve the problems of operator's bodily injury, danger of metal sheet stamping device, structural design defects, etc., and achieve the effect of improving stability, improving quality, and efficient and safe stamping operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

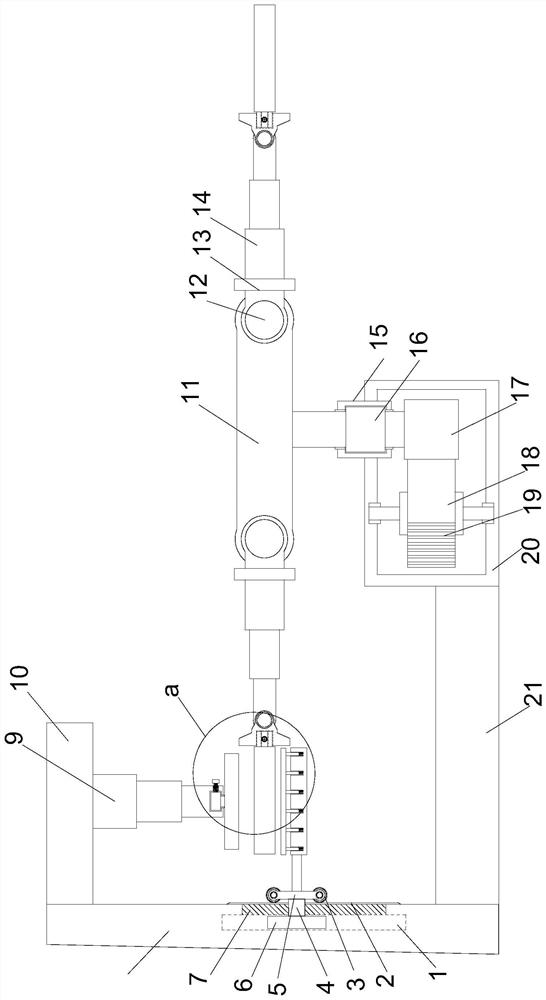

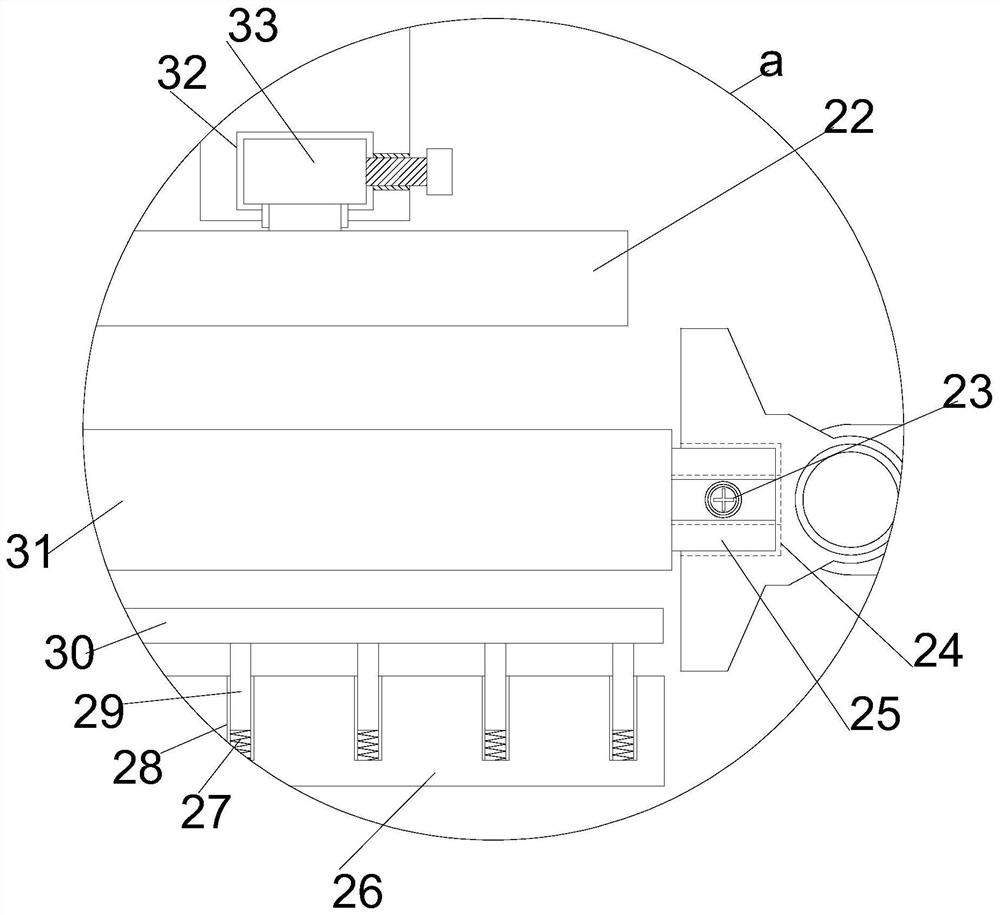

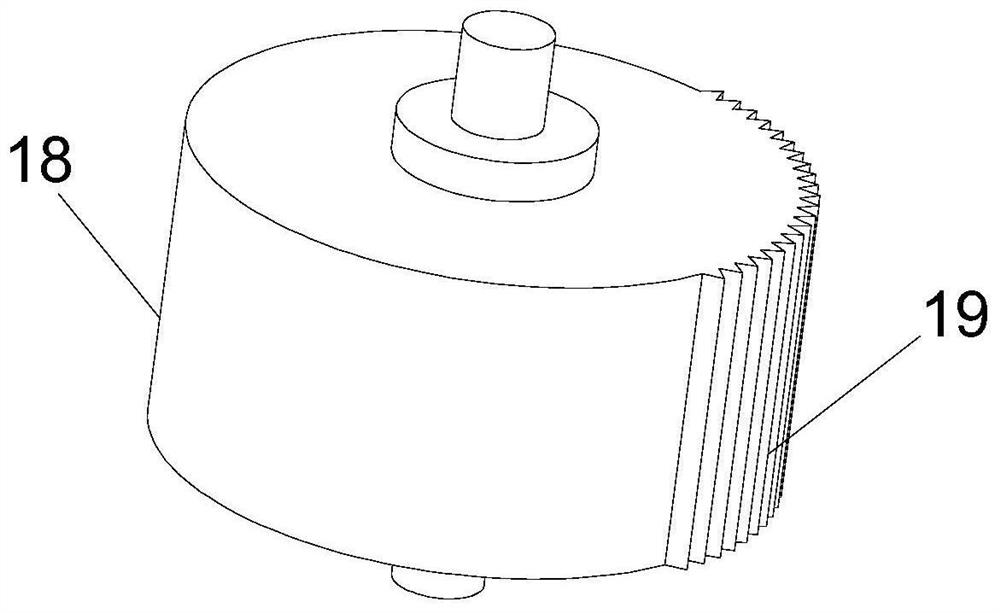

[0021] see Figure 1~3 , in an embodiment of the present invention, a lower die displacement type continuous thin plate stamping device includes a horizontally arranged support installation plate 21, a support installation column 8 is arranged vertically upward on the left end of the support installation plate 21, and the upper end of the support installation column 8 The top mounting plate 10 is arranged horizontally to the right, the right end of the support mounting plate 21 is vertically provided with a transmission installation cover 20, and the upper right end of the transmission installation cover 20 is vertically provided with a limit bearing sleeve 15, and the said matching limit bearing sleeve 15 is vertically arranged. The limit rotating shaft 16 is arranged vertically, the upper end of the limit rotating shaft 16 is horizontally provided with a steering mounting plate 11, the lower end of the limit rotating shaft 16 is coaxially provided with a steering gear 17, and...

Embodiment 2

[0024] On the basis of Embodiment 1, through the cooperation of the moving gear 3 and the moving rack 2, the lifting and lowering adjustment of the lifting installation plate 5 is realized, and then under the cooperation of the guiding installation column 6 and the guiding installation groove 1, a stable guiding lifting is realized, so that The position-limiting mounting plate 26 stops at a certain height. At this time, under the action of the return spring 27, the displacement guide column 29 extends out in cooperation with the displacement guide groove 28, realizing the support of the displacement support plate 30 to the lower template 31, and significantly improving the stamping process. stability, while improving the precision and quality of sheet metal stamping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com