Simple internal bracing clamp for friction-stir welding circumferential weld

A technology of friction stir welding and internal support fixtures, which is applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of high manufacturing cost, large force in the tangential direction, and high cost, so as to ensure welding quality and avoid welding Staggered stitching and short manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

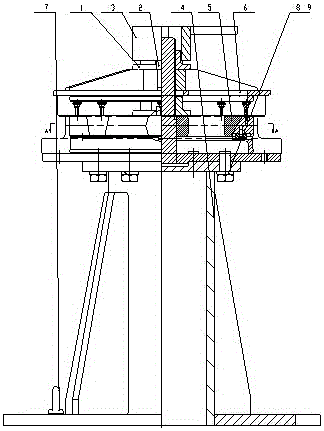

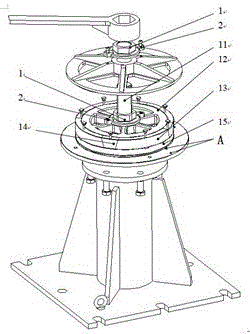

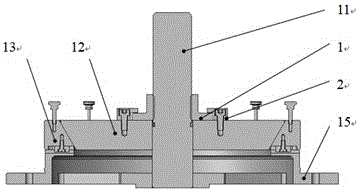

[0023] see Figure 1-4 , a simple internal support fixture for friction stir welding girth seam, including a pressure plate assembly 6, a clamp body 5, and a base assembly 4 for fixing the clamp body 5, the clamp body 5 includes a clamping block, an L-shaped block 3, and a wedge 12 , screw rod 11 and positioning plate 15, the clamping block of the present embodiment includes four main clamping blocks 13 and four secondary clamping blocks 14 arranged uniformly and at intervals, the clamp body 5 is welded with the positioning plate 15 and the screw rod 11 and then The oblique wedge 12, the L-shaped block 3, the main clamping block 13 and the auxiliary clamping block 14 are combined;

[0024] The pressure plate assembly 6 is located above the clamp body 5, the base assembly 4 is located below the clamp body 5, the pressure plate assembly 6 is placed on the clamp body 5, and the screw rod 11 of the clamp body 5 is positioned to ensure that the pressure plate assembly 6 and the wed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com