Cutter bar device of multi-functional digital controlled lathe

A CNC lathe, multi-functional technology, applied in the direction of tool holders, etc., can solve the problems of increasing the assembly complexity of the clamping device, no positioning structure, and inaccurate installation of the clamping groove, so as to save tool change and tool setting time, The effect of improving production efficiency, improving processing accuracy and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

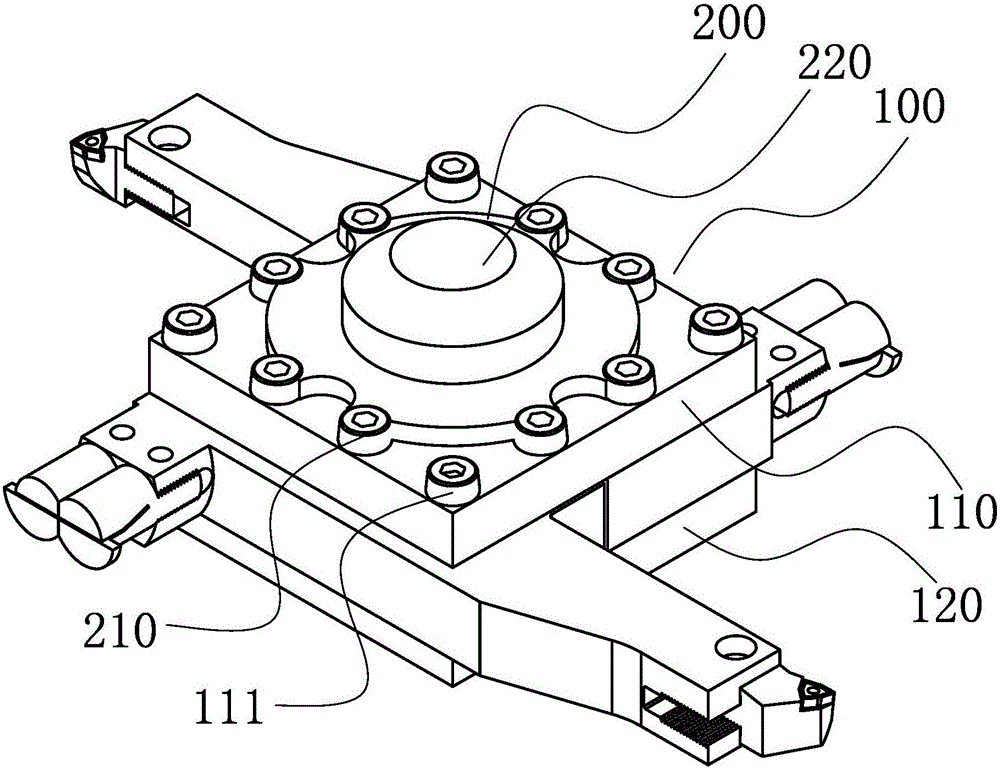

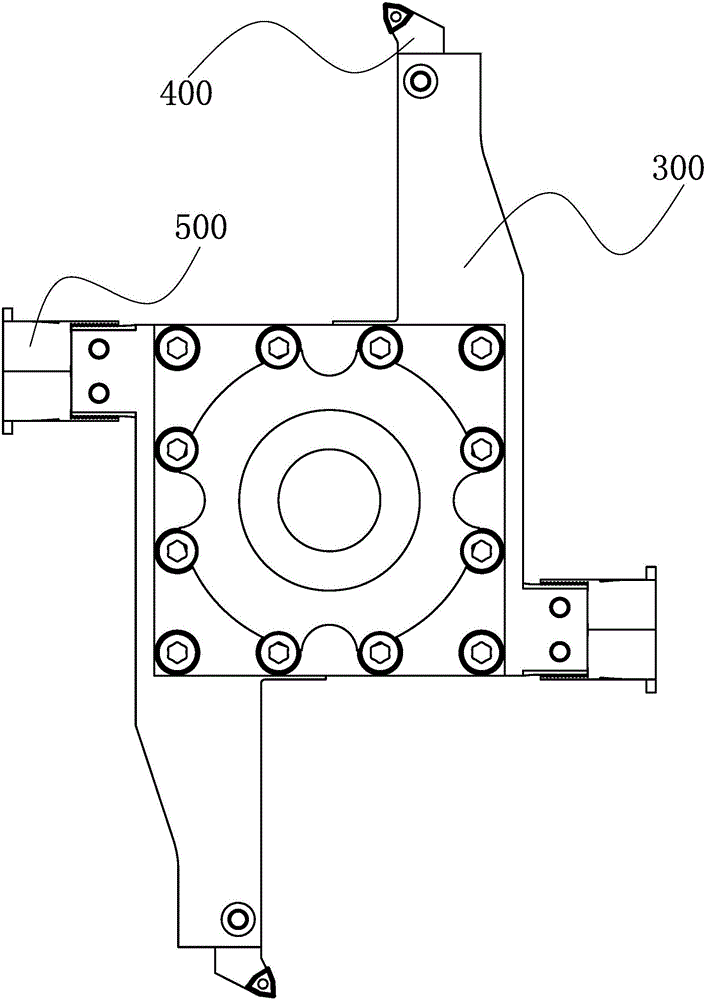

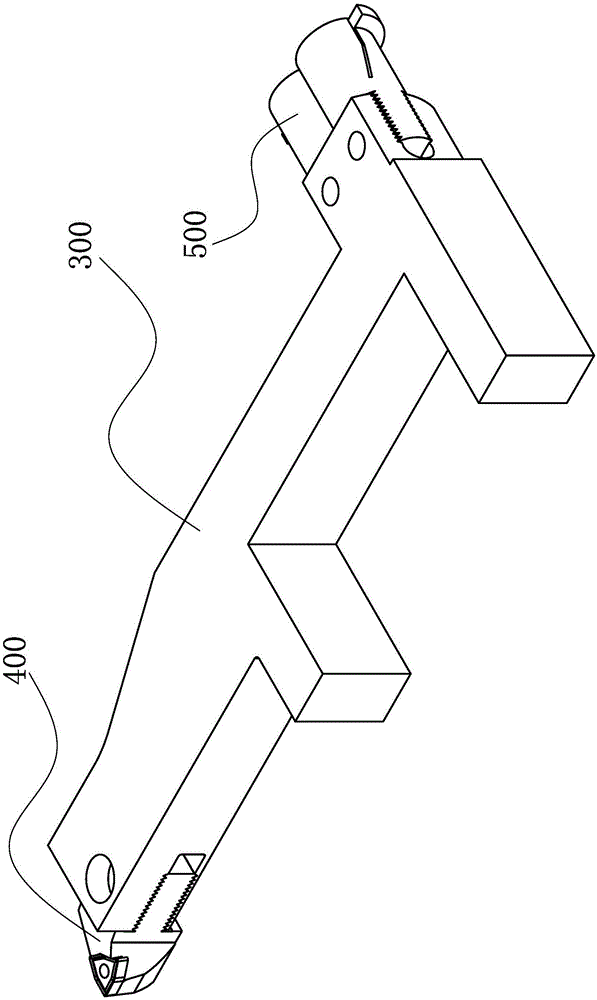

[0033] Such as figure 1 with figure 2 As shown, a kind of multifunctional numerical control lathe tool holder device provided by the present invention comprises: a tool rest 100, a first flat plate 110 and a second flat plate 120 are arranged along the thickness direction of the tool rest 100, and the first flat plate 110 and the second flat plate Two flat plates 120 are integrally formed; a rotating shaft seat 200 is revolving, and a plurality of first through holes 210 are arranged in a circular array along the axial direction of the rotating shaft seat 200, and the rotating shaft seat 200 is fixed on the tool holder 100 by threaded fasteners ; Two knife rods 300 are symmetrically arranged on both sides of the knife ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com