A closed type washing machine top cover dust removal system

A technology of dust removal system and washing machine, which is applied in the direction of dust removal, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of poor cleaning effect and great environmental hazards, and achieve easy collection, high degree of automation, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

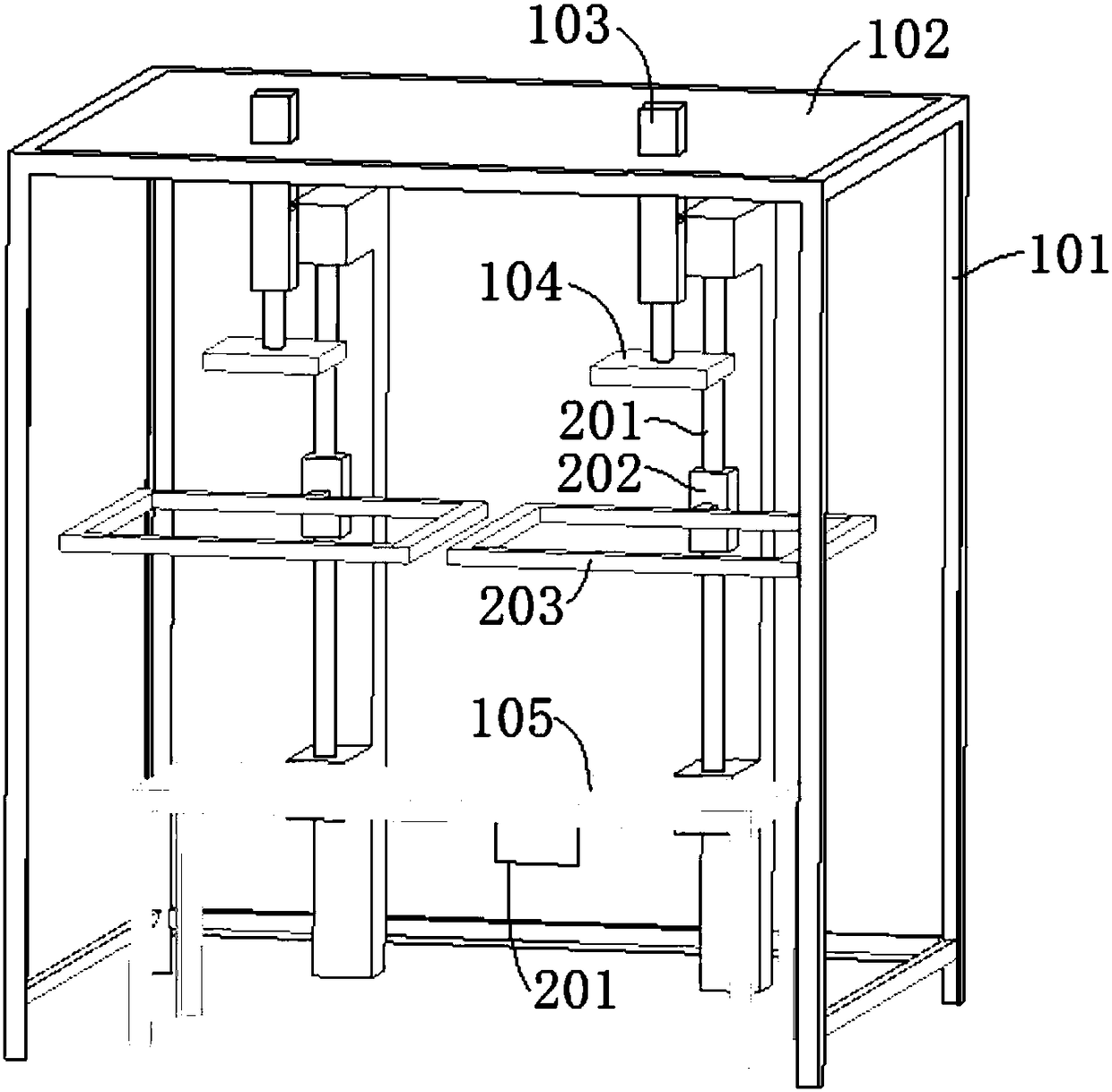

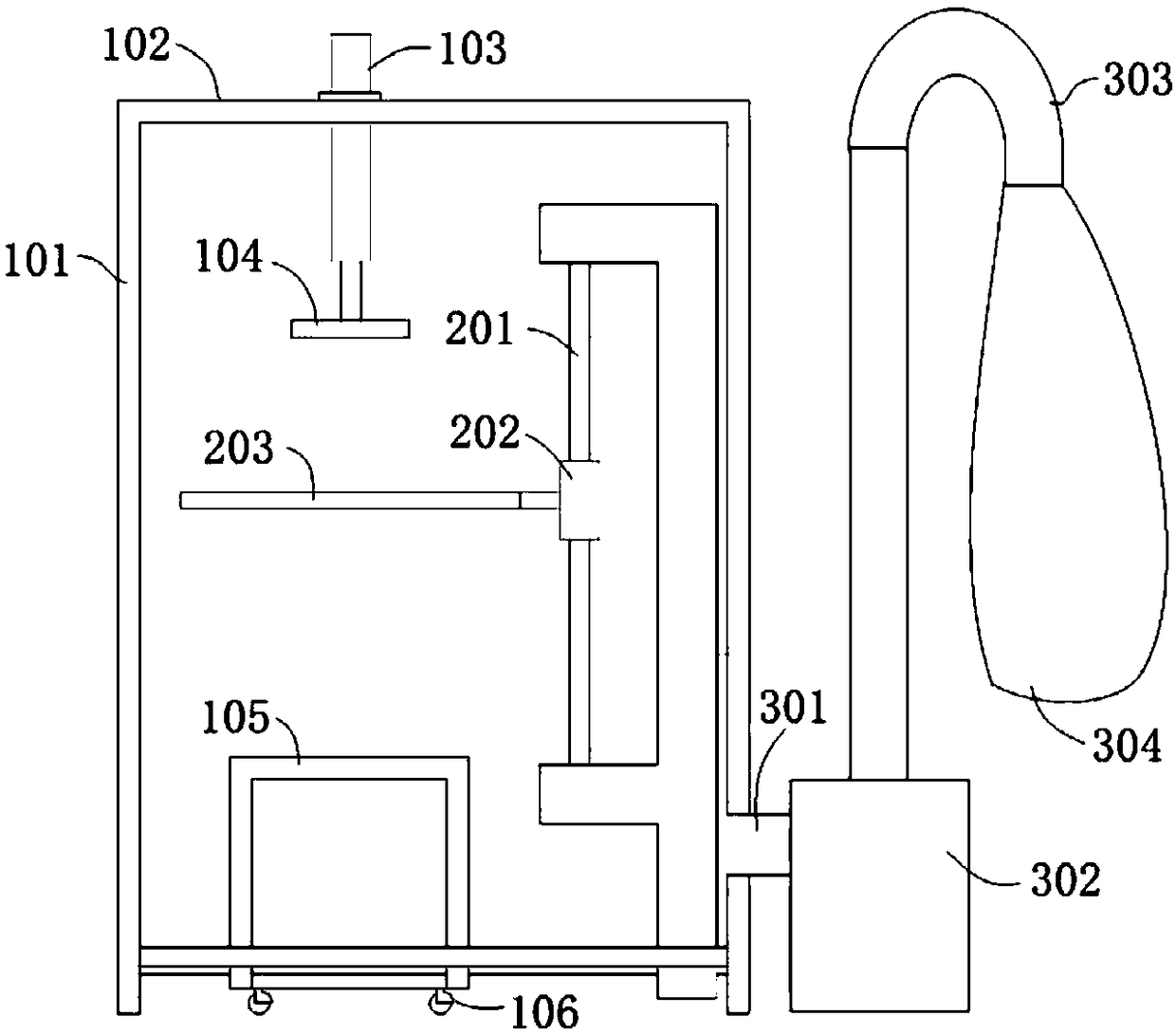

[0037] combine figure 1 , a closed washing machine top cover dust removal system in this embodiment includes a support mechanism and a cleaning mechanism. The support mechanism includes a bracket 101, a cylinder 103 and a loading platform 105, and the bracket 101 is formed by connecting four vertically arranged legs. , a top plate 102 is provided on the top of the bracket 101 . The side wall of the bracket 101 can be closed or open, and there is no specific limitation in this embodiment.

[0038] The main purpose of setting the top plate is to install the cylinder 103, and other support mechanisms can also be used to directly replace the top plate to install the cylinder 103. A vertically downward cylinder 103 is installed on the top plate 102, and a pressure plate 104 is connected to the piston rod of the cylinder 103, and the pressure plate 104 cooperates with the stage 105 to compress the workpiece. When spraying air, if the top cover is not pressed tightly, dust will eas...

Embodiment 2

[0043] The dust removal system for the top cover plate of a closed washing machine in this embodiment has the same basic structure as that of Embodiment 1, the difference is that in this embodiment, two sets of air injection mechanisms 203 are arranged in the same support mechanism, and two sets of air injection mechanisms 203 are provided. Mechanisms 203 can share one control system, so that two sets of air injection mechanisms 203 can work synchronously, further improving the processing efficiency.

[0044] There are rollers at the bottom of the stage 105. If there are no rollers, the workpiece must be unloaded and placed on the stage 105 every time it is processed. The operation is troublesome. After setting the rollers, the workpiece can be placed directly on the stage. It is transported to the bottom of the platen, and then transported out after air jet cleaning, which greatly saves time and reduces the labor intensity of workers.

Embodiment 3

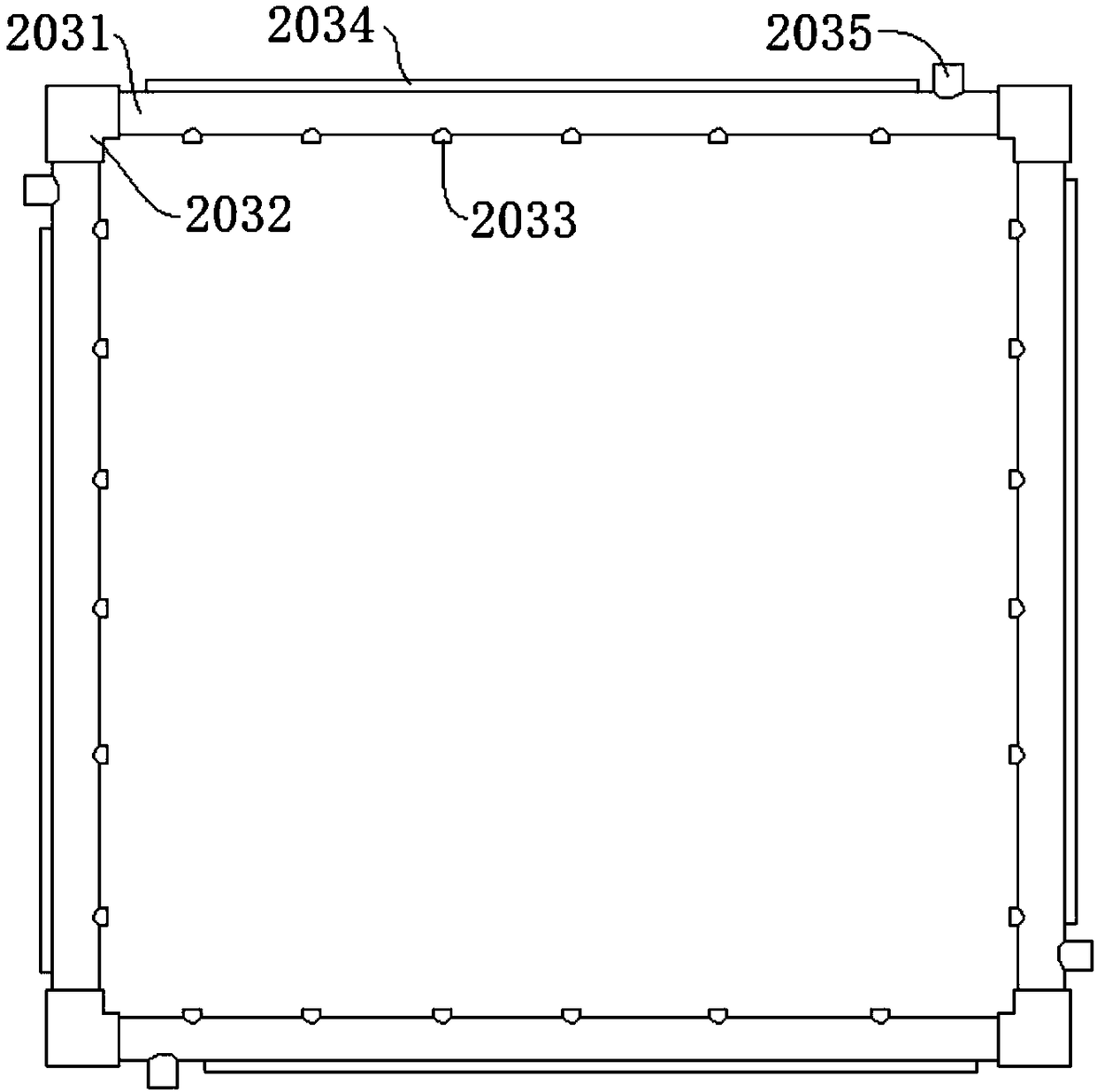

[0046]The dust removal system for the top cover of a closed washing machine in this embodiment has the same basic structure as that of Embodiment 2, except that the air nozzles 2033 on the same air injection pipe are located on the same straight line, and the axis of the air nozzles 2033 is in line with the The included angle in the horizontal direction is 10° (other angles can also be set as required), and it is biased below the horizontal plane. Setting a certain inclination makes it easier to clean out the dust in the crevice, and makes the dust drift toward the jet direction, which can prevent the suspended dust from attaching to the cleaned workpiece surface again to a certain extent, and it is easier to collect the cleaned dust.

[0047] Further, each air spray pipe 2031 is connected with a light strip 2034, and the light strip 2034 can be wound on the air spray pipe 2031, or directly tied to the air spray pipe 2031 with a cable tie, without specific limitation.

[0048]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com