Onion cleaning, sorting and cutting integrated processing production line

A production line and sorting technology, applied in metal processing, solid separation, chemical instruments and methods, etc., can solve problems such as time-consuming and labor-intensive, increased labor costs, and insufficient classification standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

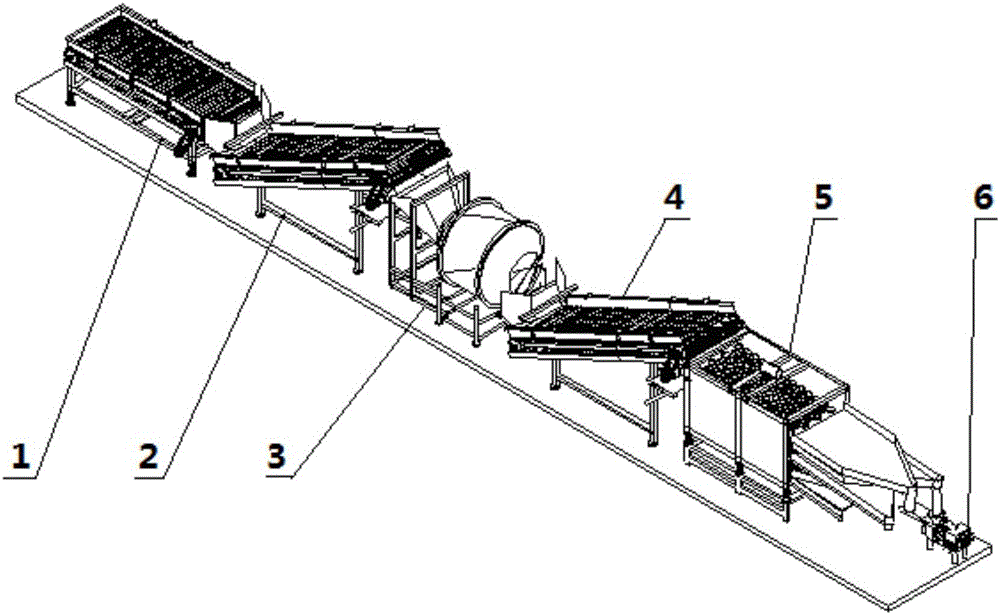

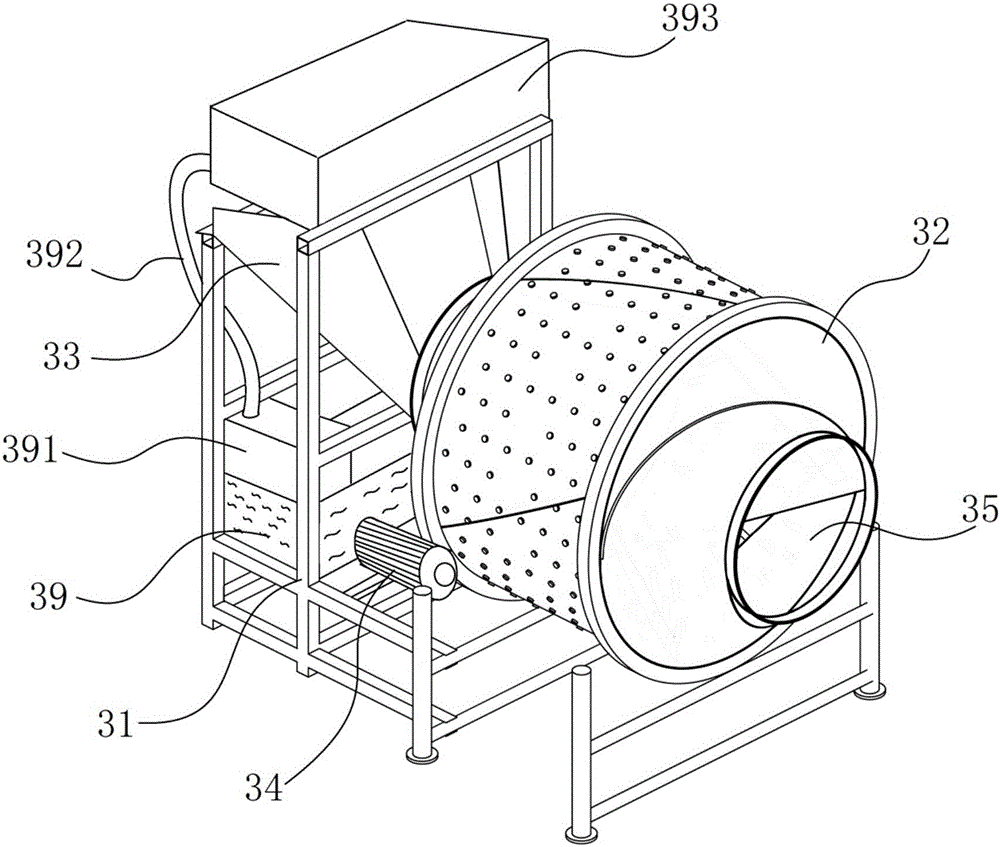

[0046] Embodiment 1: An onion cleaning, sorting and cutting integrated processing production line is composed of vibrating screen equipment 1, first conveying equipment 2, cleaning equipment 3, second conveying equipment 4, sorting equipment 5 and cutting equipment 6, wherein: The end of the vibrating screen equipment 1 is connected to the beginning of the first conveying equipment 2, the end of the first conveying equipment 2 is connected to the feeding end of the cleaning equipment 3, the discharge end of the cleaning equipment 3 is connected to the beginning of the second conveying equipment 4, and the first The end of the second conveying device 4 is connected to the feed inlet of the sorting device 5 , and the sorting device 5 includes a plurality of discharge ends, and the discharge ends are all connected to corresponding cutting devices 6 . Feed the harvested onions to the vibrating screen equipment 1, the vibrating screen equipment 1 can vibrate and transport, sieve off...

Embodiment 2

[0050] Embodiment 2: On the basis of implementing 1, the sorting device 5 includes a chassis 51, a vibrating screen spring 52, a vibrating motor 53, a frame 54, a mesh sieve plate 55, a guide plate 56, and a feeding port 57 , the bottom of the frame 54 is connected to the bottom frame 51 through six vibrating screen springs 52, the vibrating motor 53 is placed above the frame 54, and four layers of mesh sieve plates are installed from top to bottom in the frame 54 55. The ends of the mesh sieve plates 55 are connected to their corresponding guide plates 56, the ends of the guide plates 56 are pointed, and the ends of the guide plates 56 are provided with corresponding feeding ports 57. Several sieve holes 58 are evenly distributed, and the sieve holes 58 on each layer of mesh sieve plate 55 have the same aperture, and the inner diameters of each layer of sieve holes 58 of the mesh sieve plate 55 are arranged in layers from large to small from the upper layer to the bottom layer...

Embodiment 3

[0054] Embodiment 3: On the basis of Embodiment 1 or 2, the cutting device 6 includes a casing 610 and a pushing mechanism 620 placed in the casing 610, a blanking mechanism 630, a righting guide mechanism 640 and a cutting mechanism 650, pushing The mechanism 620 is connected to the unloading mechanism 630 and placed below it, the pushing mechanism 620 is connected to the righting guide mechanism 640, and the cutting mechanism 650 is installed inside the righting guide mechanism 640. After the onion material enters the cutting device 6, under the action of the pushing mechanism 620, the onion material falls and pushes in a single and orderly manner in the unloading mechanism 630 at a uniform speed, avoiding the clogging or blocking of the cutting opening caused by the accumulation of multiple onion materials. For problems such as disordered cutting parts, the righting guide mechanism 640 can select the individual body position of the onion, and transport the onion material wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com