Dry pair roller strong magnetic separator

A magnetic separator, dry technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of large production line area, difficult tailings treatment, water and power consumption, etc. Small area, reduced sorting difficulty, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

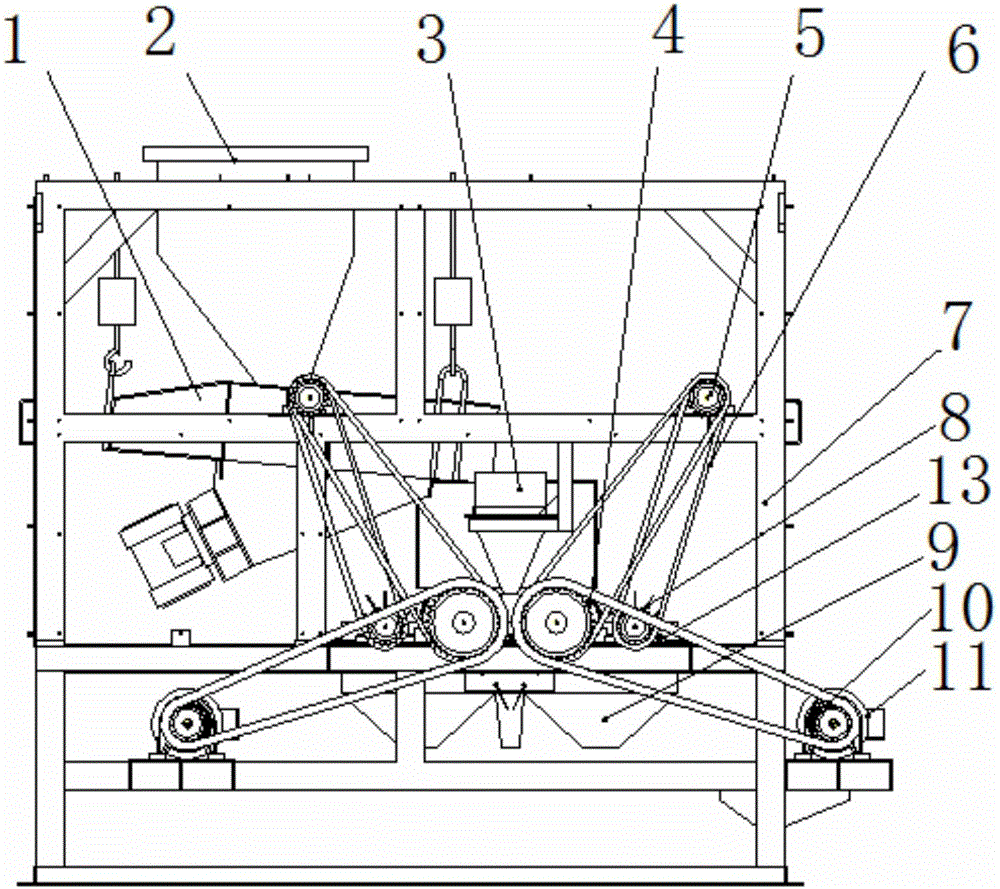

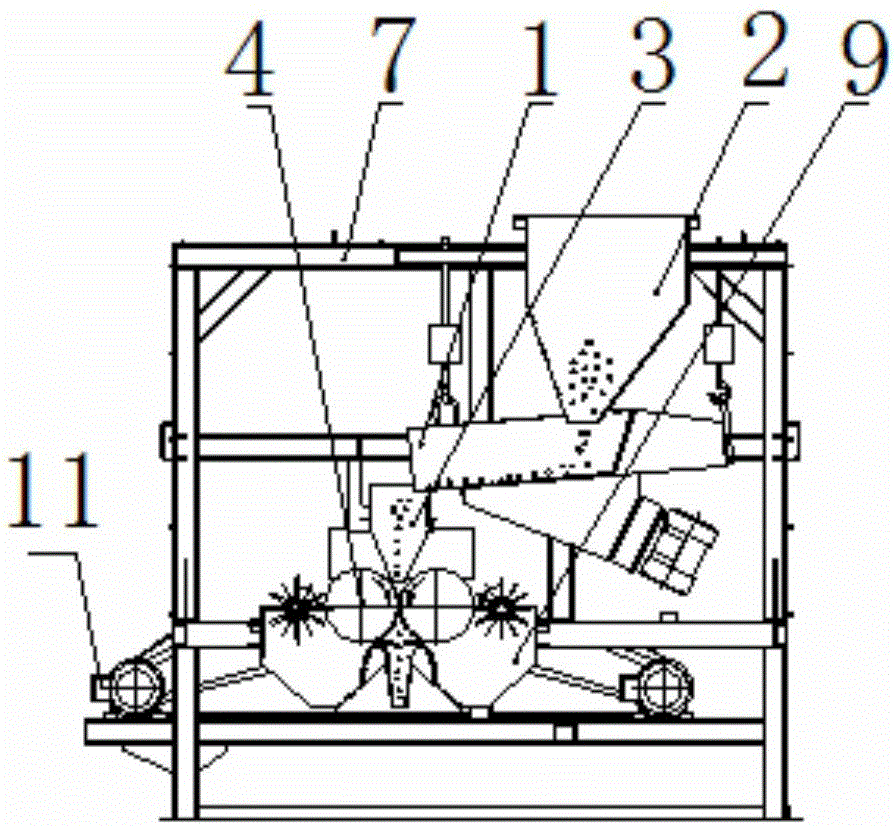

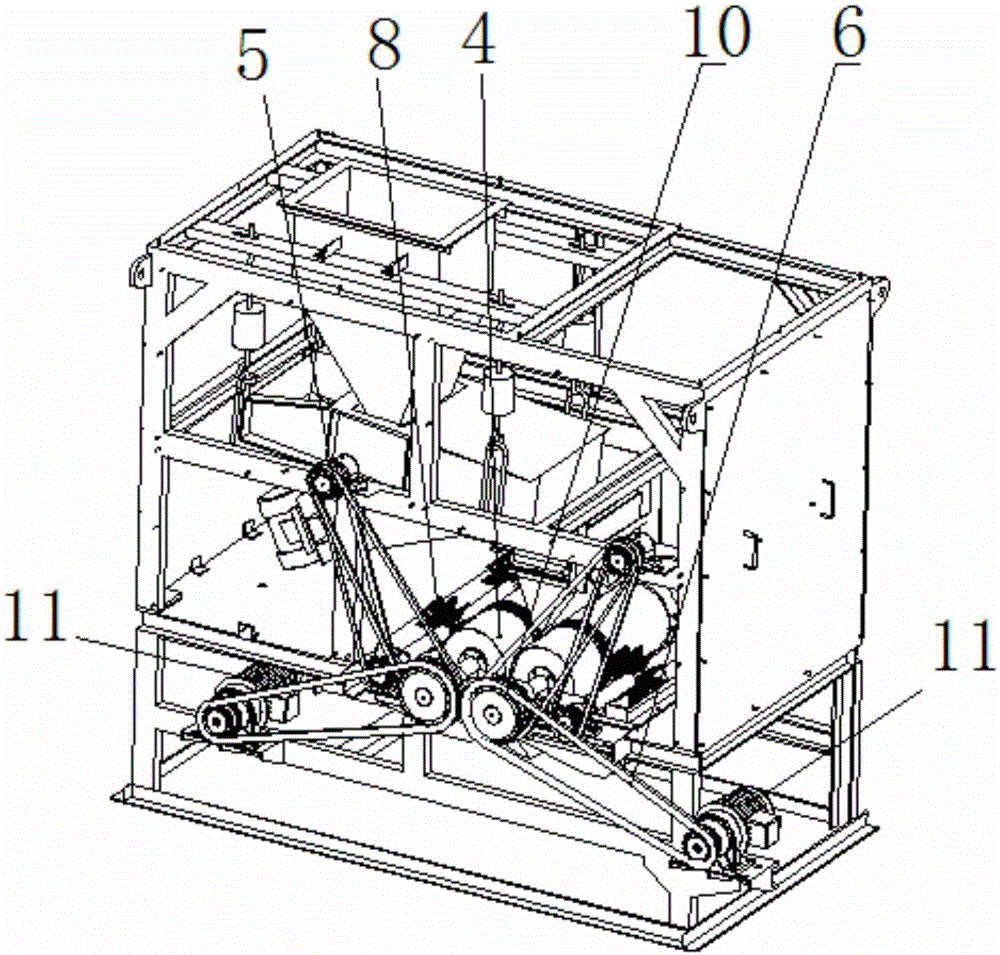

[0036] Embodiments of the present invention are as follows, see Figure 1 to Figure 6, a dry-type double-roller strong magnetic separator, including a support frame 7, several sprockets 10 and several transmission chains 6, and a feed hopper 2 arranged at the top of the support frame 7, the middle part of the support frame 7 is opposite to A pair of electromagnetic rollers 4 are provided, and each electromagnetic roller 4 is wound with at least two sets of relatively parallel toothed magnetic poles 17. The left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com