Preparation method and application of hydroxy ferric sulfate sludge-based charcoal

A technology of ferric hydroxysulfate and biochar is applied in the fields of water pollutants, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problems of inability to arsenic, adsorption, etc. Realize the effect of reducing and harmless

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of ferric hydroxysulfate sludge-based biochar, including the following steps:

[0024] 1. Add 9.2mol / L sulfuric acid to the municipal sludge with a water content of 2wt% in the independent cell air lift plug flow reactor to adjust the pH to 4, and react for 24h to make the sludge Endogenous iron precipitates and the precipitation rate is 50%;

[0025] 2. Inject acidophilic Thiobacillus ferrooxidans into the above sludge, the inoculation amount is 10wt%, the sludge is continuously aerated after inoculation, stay in the reactor for 48h, and react to Fe in the sludge solution 2+ The oxidation rate is greater than 95% to obtain ferric hydroxysulfate sludge;

[0026] 3. The above-mentioned ferric hydroxysulfate sludge is dehydrated by press filtration, the moisture content of the sludge after dehydration is 55-65%, and the dehydrated sludge is dried at 105°C for 8 hours;

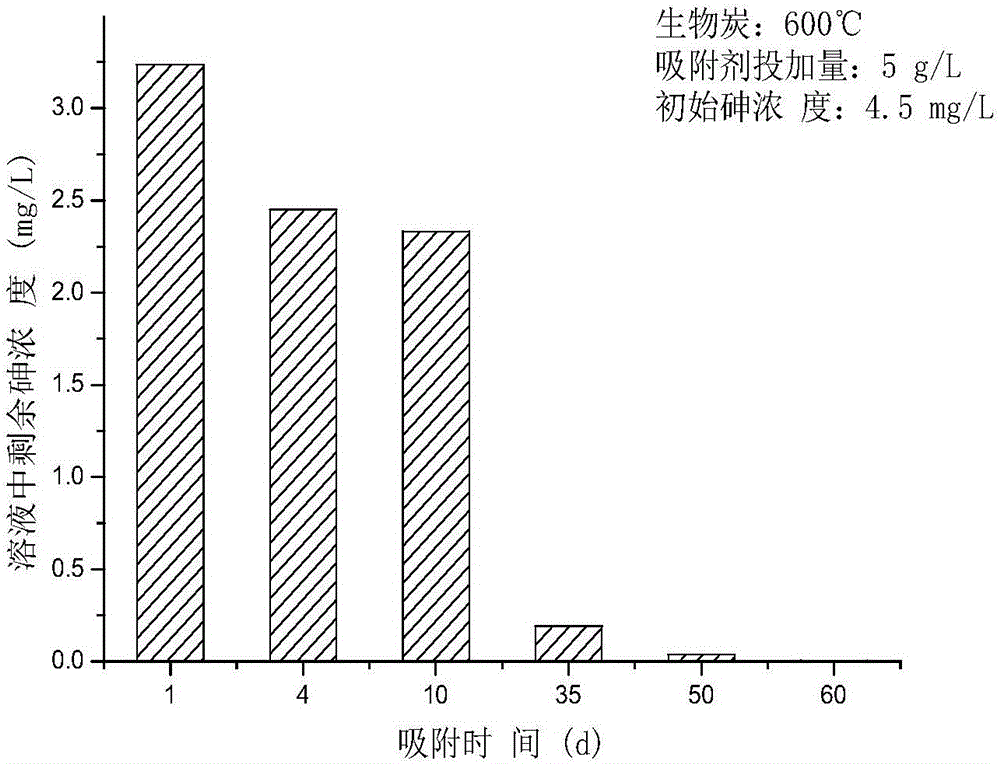

[0027] 4. Grind the above-mentioned dried sludge through a 2mm sieve, and put the sieved s...

Embodiment 2

[0033] A preparation method of ferric hydroxysulfate sludge-based biochar, including the following steps:

[0034] 1. Add 9.2mol / L sulfuric acid to the municipal sludge with a water content of 3wt% to adjust the pH to 4 and react for 48h to make the sludge The endogenous iron is precipitated and the precipitation rate is 80%;

[0035] 2. Inject acidophilic Thiobacillus ferrooxidans into the above sludge, the inoculation amount is 10wt%, the sludge is continuously aerated after inoculation, stay in the reactor for 48h, and react to Fe in the sludge solution 2+ The oxidation rate is greater than 95% to obtain ferric hydroxysulfate sludge;

[0036] 3. The above-mentioned ferric hydroxysulfate sludge is dehydrated by press filtration, the moisture content of the sludge after dehydration is 65%, and the dehydrated sludge is dried at 105°C for 8 hours;

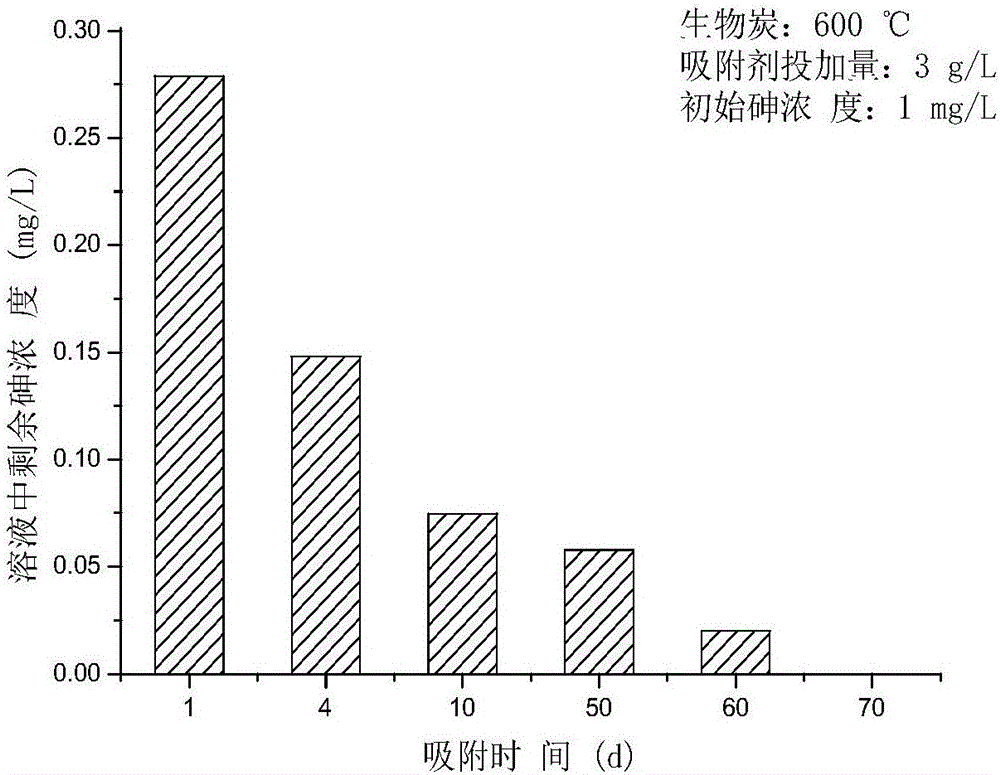

[0037] 4. Grind the above-mentioned dried sludge through a 2mm sieve, and put the sieved sludge in N 2 Pyrolysis under protection for 1h, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com