IGBT aging state detection system

A detection system and aging state technology, applied in the field of detection systems, can solve problems such as poor stability, high cost, and large-scale fluctuations, and achieve the effect of good stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

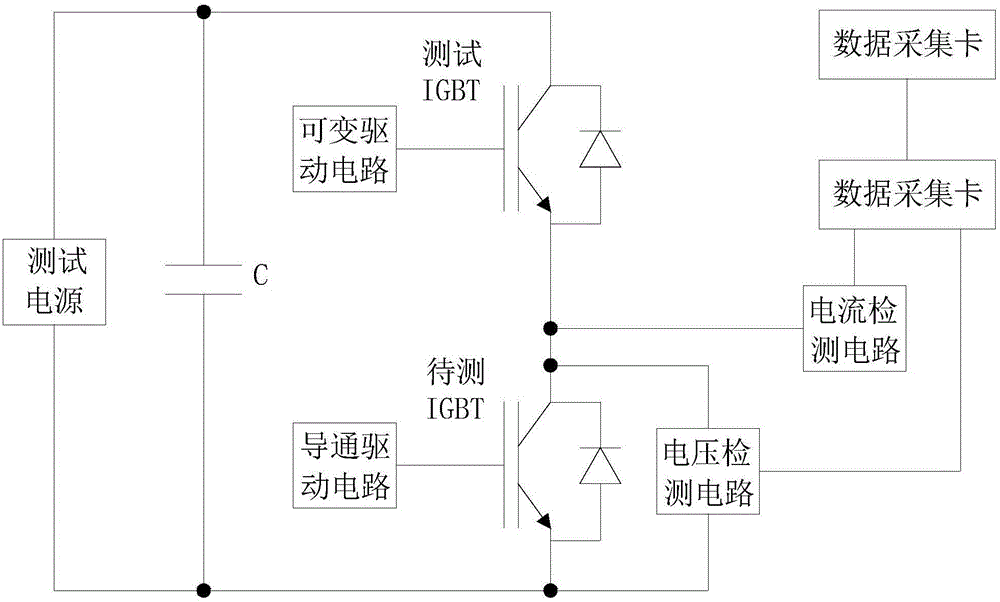

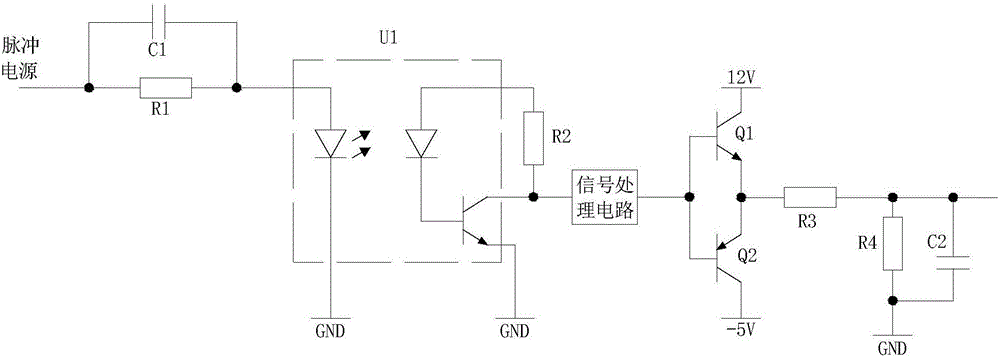

[0021] figure 1 It is a structural diagram of the present invention, figure 2 It is a schematic diagram of the variable drive circuit of the present invention, image 3 Output waveform diagram for the variable drive circuit of the present invention, Figure 4 For the measurement result waveform diagram of the present invention, Figure 5 It is a comparison chart of the IBGT characteristic curve to be tested in the present invention. As shown in the figure, a kind of IGBT aging state detection system provided by the present invention includes a test power supply, a test IGBT, a variable drive circuit that can output continuously changing currents, and a conduction drive. circuit, acquisition unit and host computer;

[0022] The emitter of the test IGBT is connected to the collector of the IGBT to be tested, the collector of the test IGBT is connected to the positive pole of the test power supply, the negative pole of the test power supply is connected to the emitter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com