IGBT module online monitoring method

A driving circuit and driving voltage technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of IGBT module damage, high cost, and complicated state monitoring methods, so as to reduce operation and maintenance costs and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

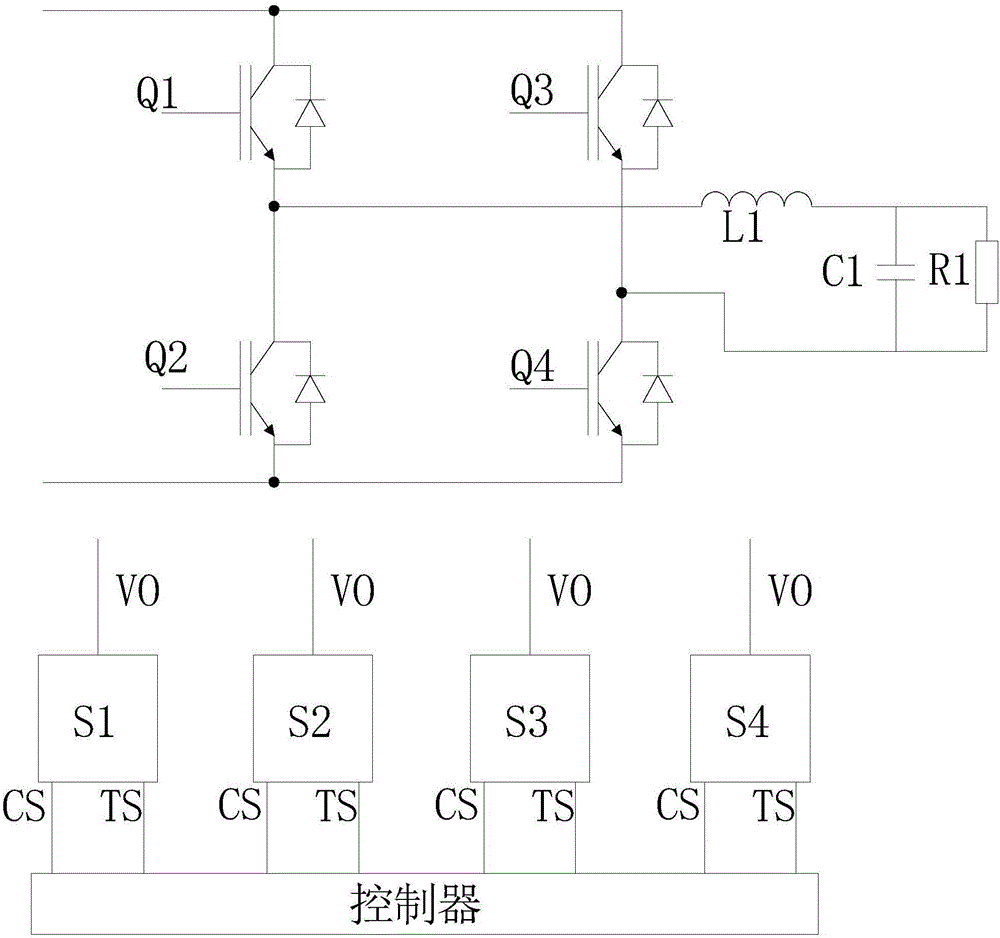

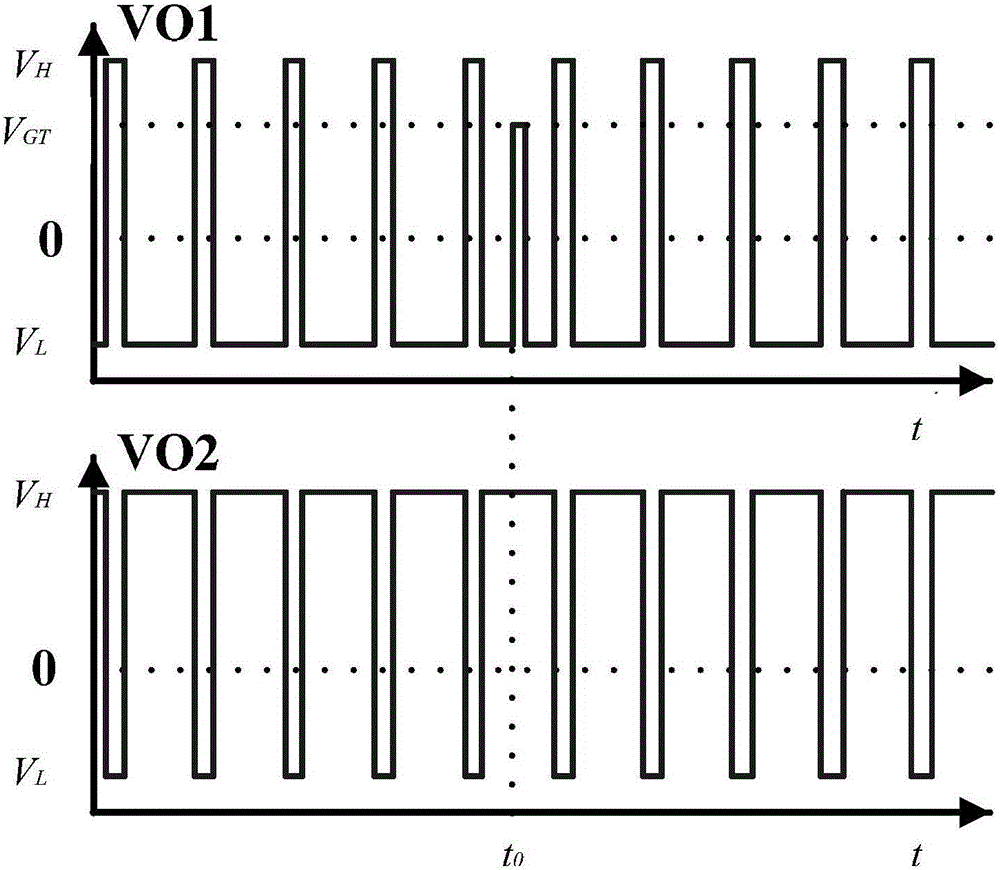

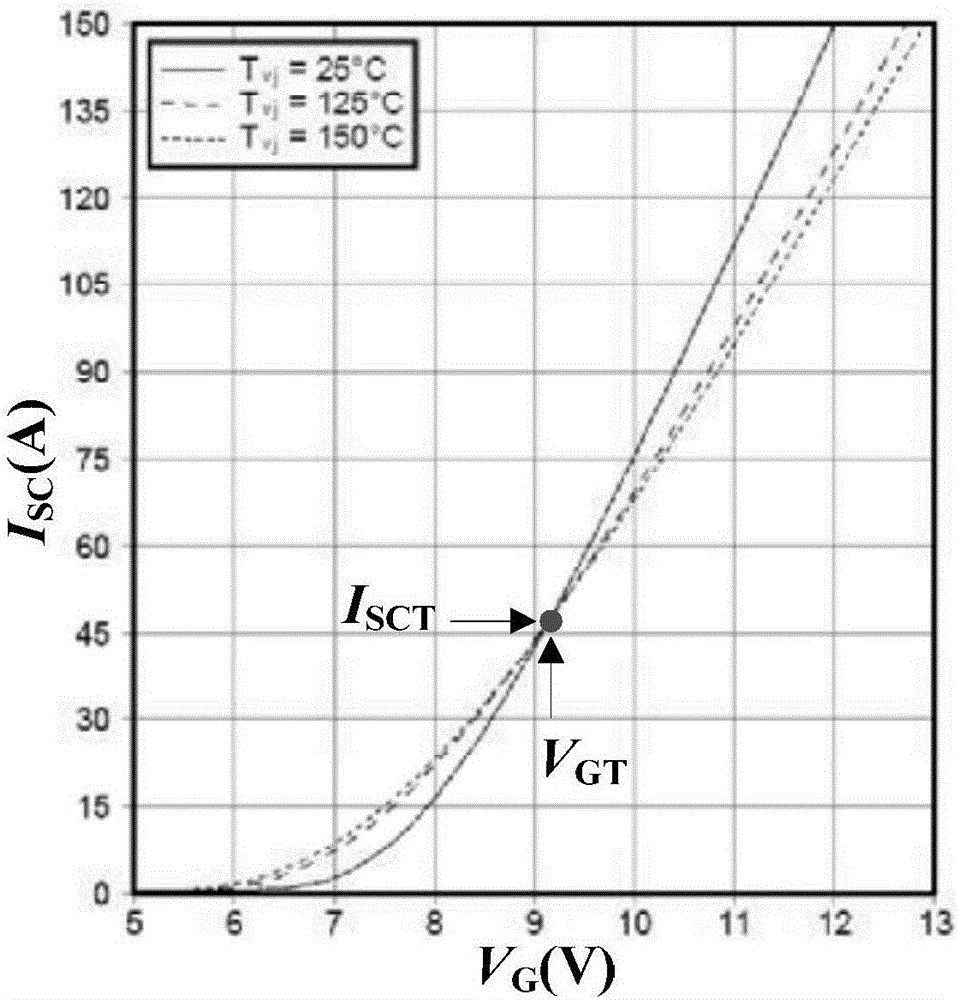

[0024] figure 1 Is a schematic diagram of the test structure of the present invention, figure 2 Is a schematic diagram of the IGBT drive voltage of the present invention, image 3 Schematic diagram of the transfer characteristic curve of the IGBT. As shown in the figure, an on-line monitoring method for IGBT modules provided by the present invention includes an IGBT module to be tested and at least one IGBT module to be tested; the IGBT module to be tested and the IGBT module to be tested form a bridge circuit, and the tested IGBT module is tested according to the following method Test the aging state of IGBT module:

[0025] Input the short-circuit driving voltage V to the IGBT module to be tested GT And control the IGBT module under test to work in the current saturation state, and input the working driving voltage V to the test IGBT module H Make the test IGBT module work normally;

[0026] Detect the short-circuit current value of the IGBT module under test in the current sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com