A multifunctional integrated pumping station

A multi-functional, pumping station technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of inability to realize liquid suction, cleaning and emptying of liquid supply relay booster pipelines, and site occupation of pumping stations Large area, environmental protection and potential safety hazards, etc., to achieve the effect of easy management and control, reducing the area of the site and the number of personnel, and improving safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

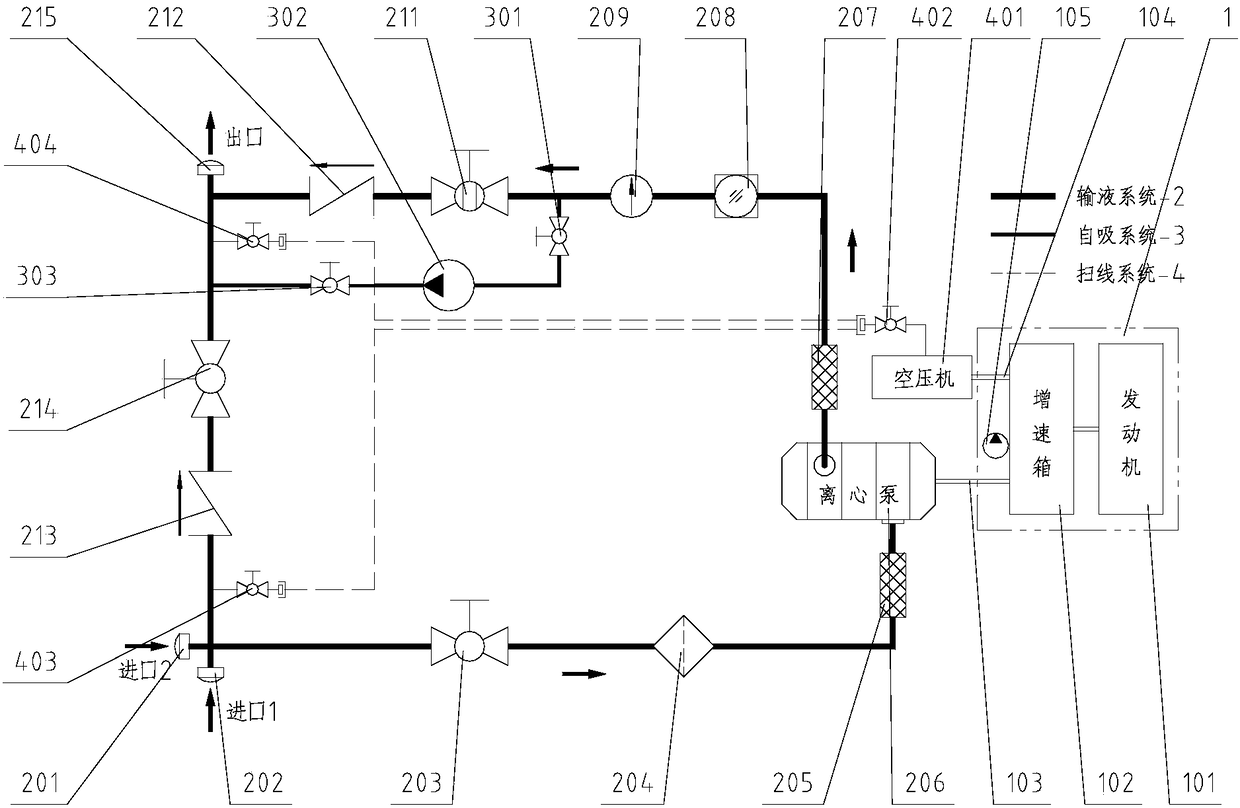

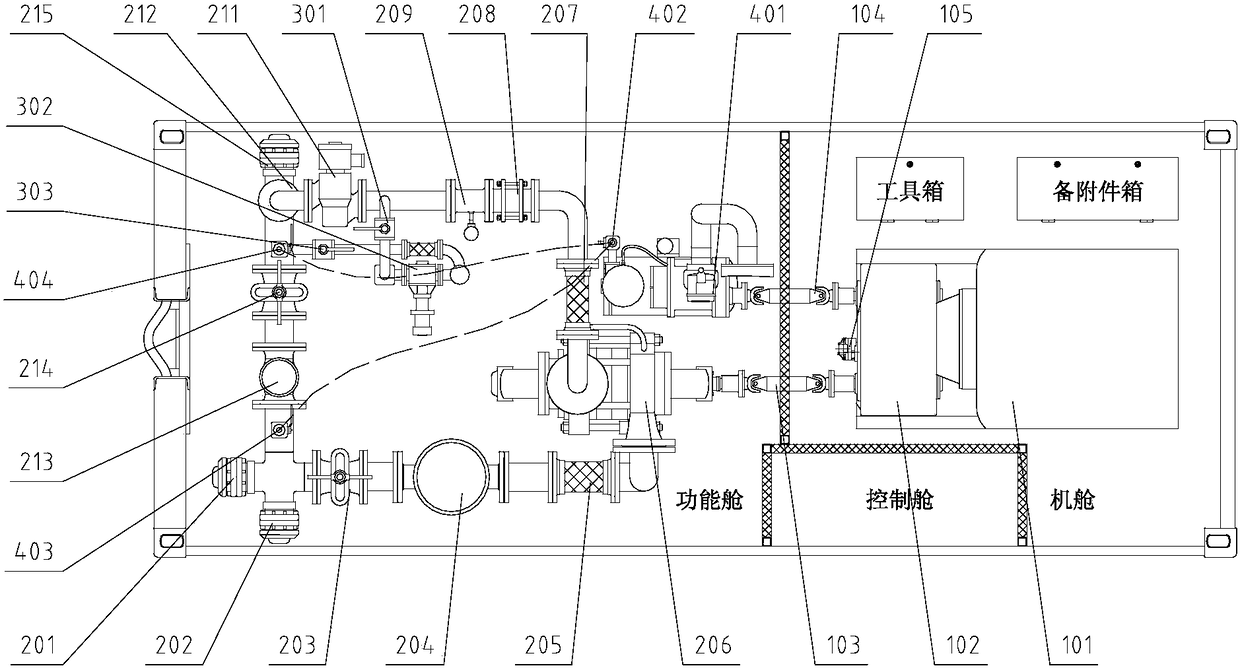

[0024] This embodiment provides a multi-functional integrated pumping station with operating functions such as self-priming, liquid supply, relay pressurization, bypass over-station and line sweeping and emptying, such as figure 1 , figure 2 As shown, it is mainly composed of power system 1, infusion system 2, self-priming system 3, line sweeping system 4 and other operating systems. Each system is integrated and arranged in the container-type pallet shelter, which can rely on the overall self-loading and unloading truck Or flat-bed container transport vehicles to achieve rapid maneuvering. The interior of the container-type pallet shelter is divided into three parts: the engine room, the function cabin and the control cabin. The power system is arranged in the engine room, and the bulkhead is treated with sound insulation; machine operation control module.

[0025] The power system 1 of this embodiment is composed of a power source 101, a speed increasing box 102, a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com