Efficient and compact type self-sucking and double-sucking pump

A compact, double-suction pump technology, used in pumps, drive pumps, pump components, etc., can solve the problems of large use limitations, inability to achieve miniaturization, and complex structure of double-suction pumps, achieving low manufacturing costs and reduced difficulty. , the effect of structure simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

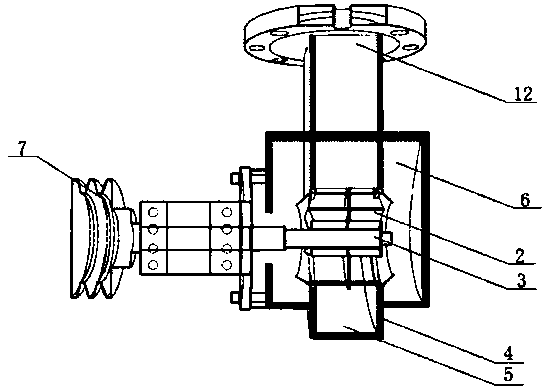

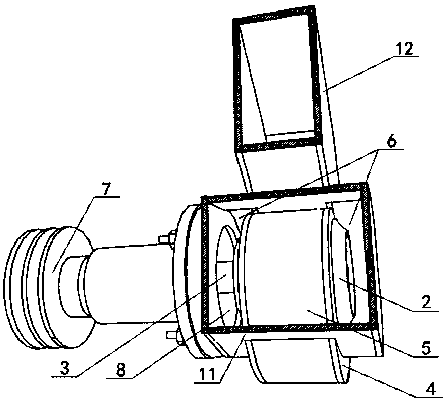

[0020] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

[0021] refer to Figure 1-4 , a high-efficiency compact self-priming double-suction pump, including a pump body 1 and a double-suction impeller 2 installed inside the pump body 1, the front end of the pump body 1 is provided with a water inlet channel 11, and the rear of the pump body 1 A water outlet channel 12 is provided at the end, and the water inlet height of the water inlet channel 11 and the water outlet height of the water outlet channel 12 are higher than the edge of the double-suction impeller 2 .

[0022] The middle position inside the pump body 1 is provided with an impeller working cavity, and the impeller working cavity is composed of two arc-shaped connecting plates 5 that are arranged in parallel in the pump body 1 and have a water suction po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com