Self-priming mechanism and automobile door lock

A suction mechanism and car door lock technology, which is applied in vehicle locks, electric car locks, building locks, etc., can solve the problems of large number of parts, large lock body size, and complicated assembly, so as to reduce the assembly process and simplify the movement relationship, reducing the compositional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

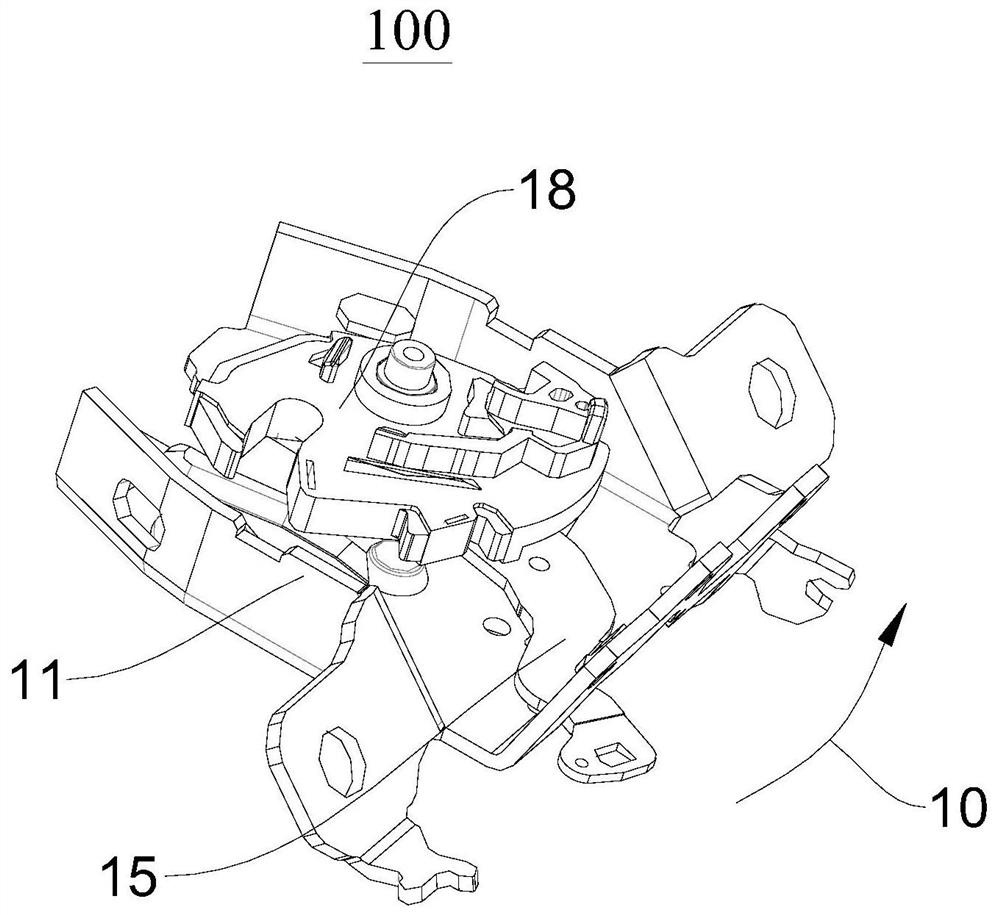

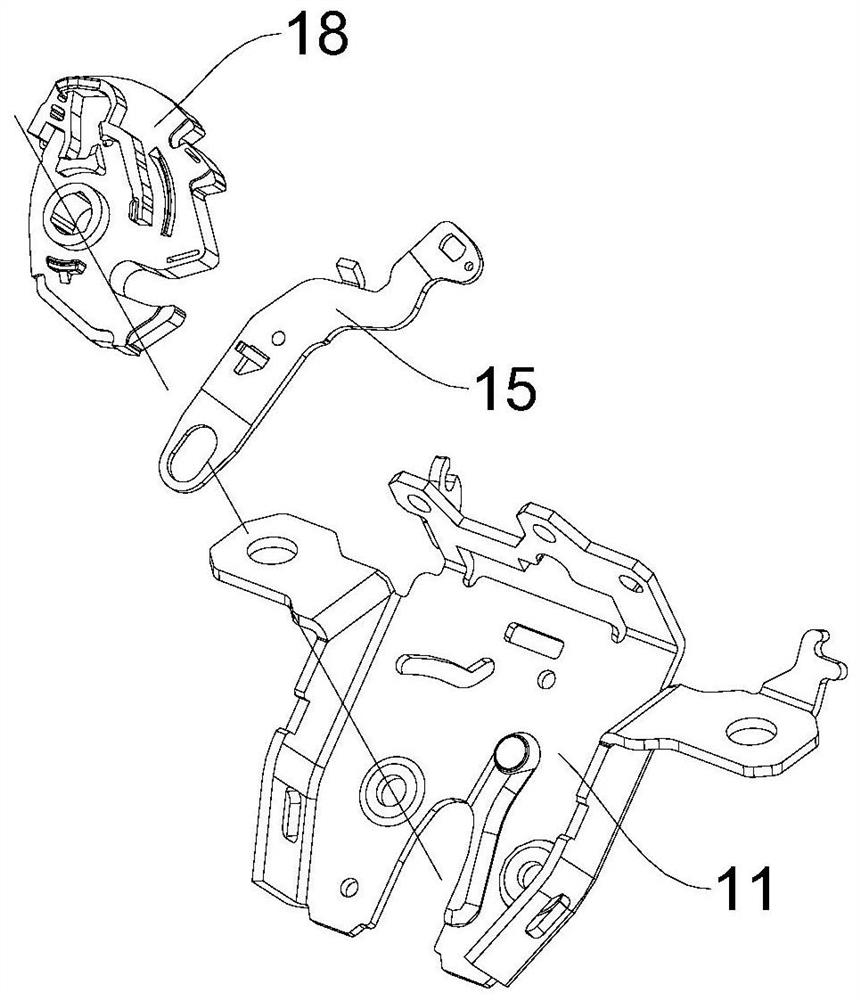

[0039] figure 1 For the structural representation of the self-priming mechanism 100 provided in this embodiment, please refer to figure 1 shown.

[0040] The self-suction mechanism 100 is used to be arranged on the automobile door lock 20 with the lock catch 24, and the parts in the self-suction door lock of the existing automobile are integrated to design, simplify its kinematic relationship, reduce the assembly process of the parts, and reduce the Small size.

[0041] Because some models of existing cars use self-priming door locks, self-priming door locks rely on a motor device to drive the self-priming mechanism inside the lock body to withstand the clamping plate inside the lock body, so that the clamping plate can move forward and backward independently. The full lock engagement position moves until the door is fully locked.

[0042] However, often for self-priming door locks, due to the addition of a self-priming mechanism, the self-priming mechanism needs to introdu...

Embodiment 2

[0063] Embodiment 2 of the present invention provides an automobile door lock 20 including the self-suction mechanism 100 as provided in Embodiment 1.

[0064] Figure 7 It is a structural schematic diagram of the automobile door lock 20 in a locked state, Figure 8 For the structure diagram of the car door lock 20 in the unlocked state, please refer to Figure 7 and Figure 8 As shown, the specific description is as follows.

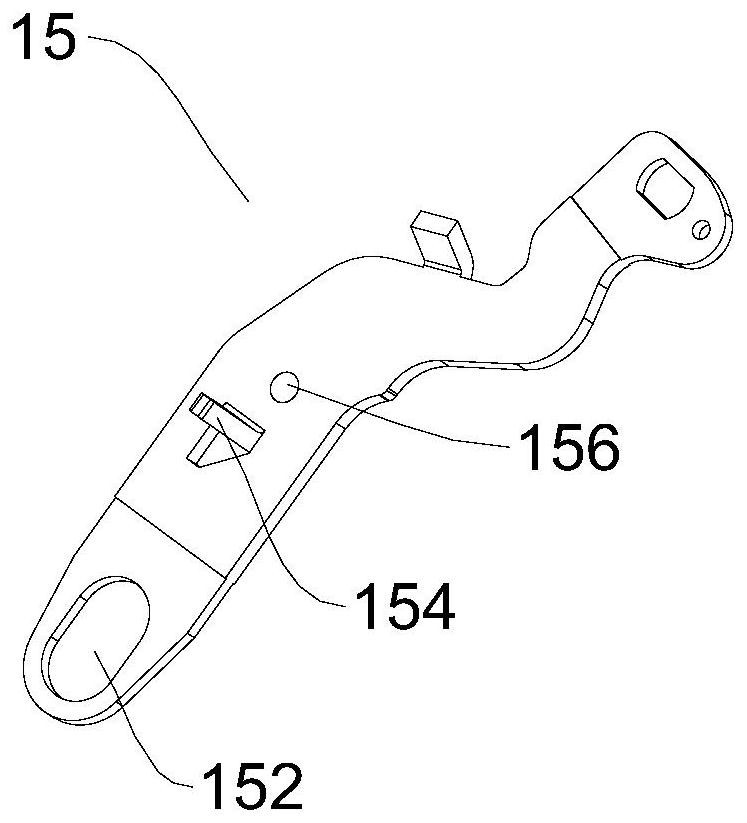

[0065] The automobile door lock 20 includes a self-suction mechanism 100 and a locking mechanism. The self-suction mechanism 100 can drive the pull wire 21 through the motor, pull the push arm 15, and drive the clamping plate 18 to rotate relative to the bottom plate 11, so that the locking mechanism inside the lock body Locking is carried out autonomously, without the need for other external forces. The locking mechanism mainly keeps the mechanically reliable locking of the lock body.

[0066] The self-suction mechanism 100 also includes claws 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com