A self-priming tailgate door lock assembly

A self-priming, door lock technology, applied in the field of car locks, can solve problems such as complex structure, large transmission force, and traditional functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing, but not as limiting the present invention:

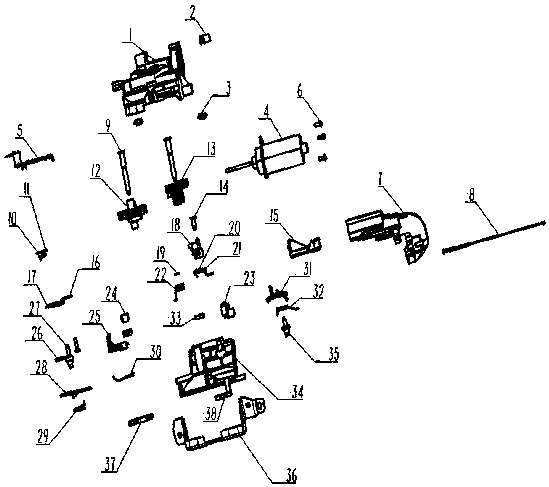

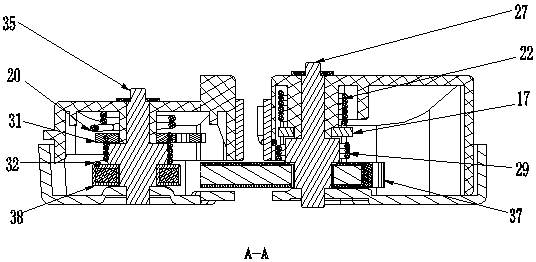

[0026] A self-priming tailgate door lock assembly, comprising a housing 1, a housing cover 34 and a cover plate 36, characterized in that:

[0027] The housing 1 is respectively provided with a large gear 12 and a double gear 13 meshing with each other through the gear shaft 9, and the large gear 12 is connected to the self-priming main movement plate 16 by transmission; Ratchet shaft 27 and ratchet shaft 35, described ratchet shaft 27 is provided with ratchet return spring 22, self-priming secondary movement plate 17, self-priming rocker arm return spring 29 and ratchet 37, and described ratchet shaft 35 is provided with There are outwardly opening return spring 20, outwardly opening rocker arm 31, pawl return spring 32 and pawl 38. The ratchet 37 is connected to the signal rocker arm 25 in transmission, and the position signal of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com