Symmetrical multifunctional nut

A multi-functional, nut technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of single operation mode, troublesome fixing, troublesome installation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

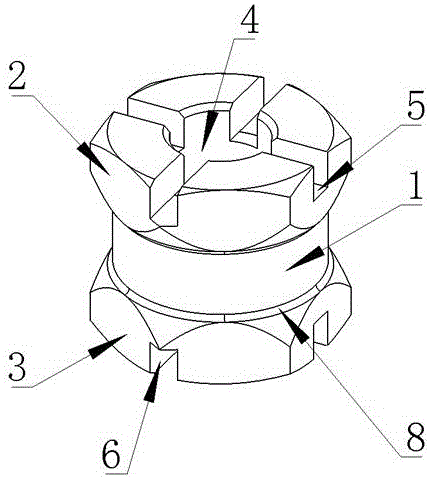

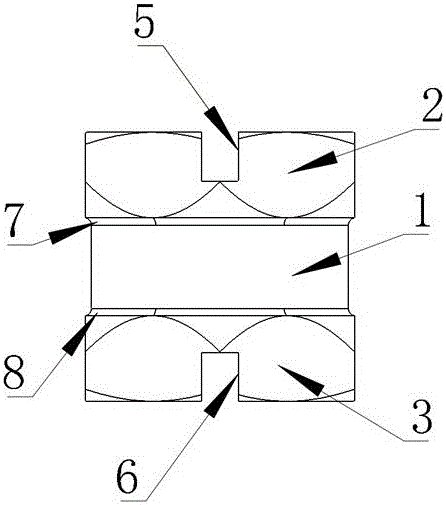

[0012] like figure 1 and figure 2 As shown, a symmetrical multifunctional nut has many different fixing methods to choose from, making its functions more diverse. It includes a nut main body 1, the upper part of the nut main body 1 is connected with an upper end fixing column 2, and the nut can be tightened through the upper end fixing column 2, so that the symmetrical multifunctional nut of the present invention and the externally threaded column or screw rod can be fastened . The lower part of the nut main body 1 is connected with a lower fixing column 3, through which the nut can be tightened, so that the symmetrical multifunctional nut of the present invention can be tightened with an externally threaded column or screw rod. The center of the nut main body 1 is a full-through threaded hole 4 of M8, and the nut of the present invention can be used on an externally threaded column or screw rod of M8, so that it can be applied to large-scale equipment and provide it with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com