Device and method for controlling a hydraulic machine

A technology for controlling valves and hydraulic pumps, which is applied in the field of hydraulic machinery, can solve the problems of reducing the total efficiency factor of hydraulic machinery, failure to use closed loops, hydraulic energy loss, etc., to achieve increased displacement volume, reliable and stable control, and better control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

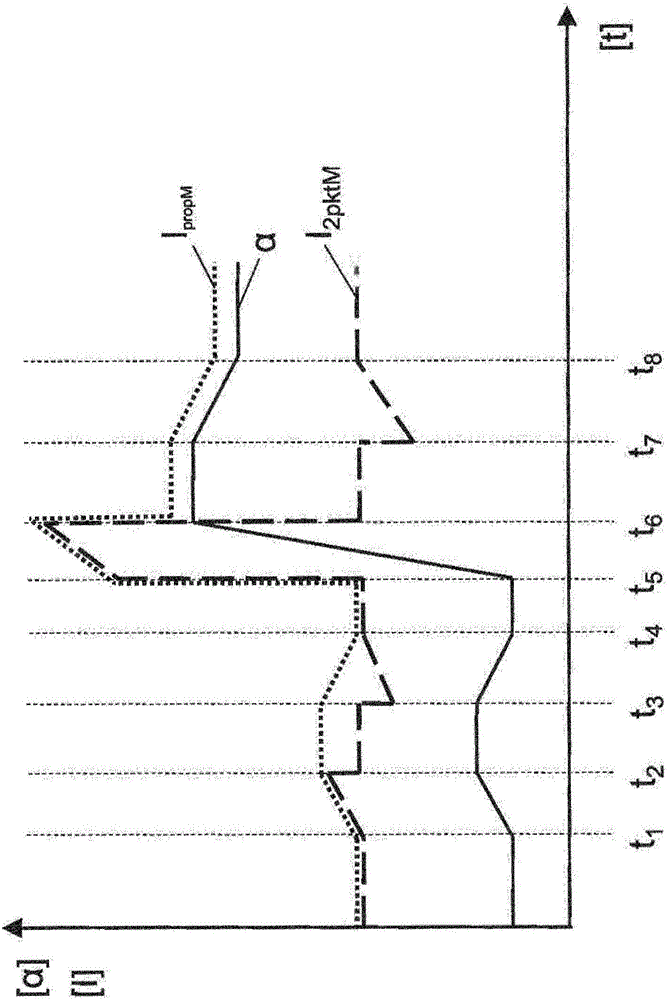

[0031] figure 1 Exemplarily shows the control current I for a proportional controlled hydraulic motor propM Form and give the hydraulic motor with 2-point control and displacement sensor to I 2pktM The form of the timing of the control signal for the actuator. The hydraulic motor is realized, for example, in a bent shaft or swash plate type. The control current controls the control valve to change the displacement angle setting by means of the exemplarily selected actuator of the axial piston hydraulic motor. At time t 1 To t 4 , The adjustment of the displacement angle α is performed for the two hydraulic motors with a relatively low control current and by applying hydraulic fluid from the low-pressure pipeline. According to this, the change runs flat, where at time t 1 And t 2 Between and t 3 To t 4 The displacement angles between them experience rise and fall respectively.

[0032] At time t 5 , A higher control signal is set, so that in addition to the control valve, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com