Balance valve for pump truck and secondary overflow valve response differential pressure control method thereof

A balancing valve and relief valve technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of hindering the development and dependence of the host equipment, and achieve the effect of more control, reasonable control and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

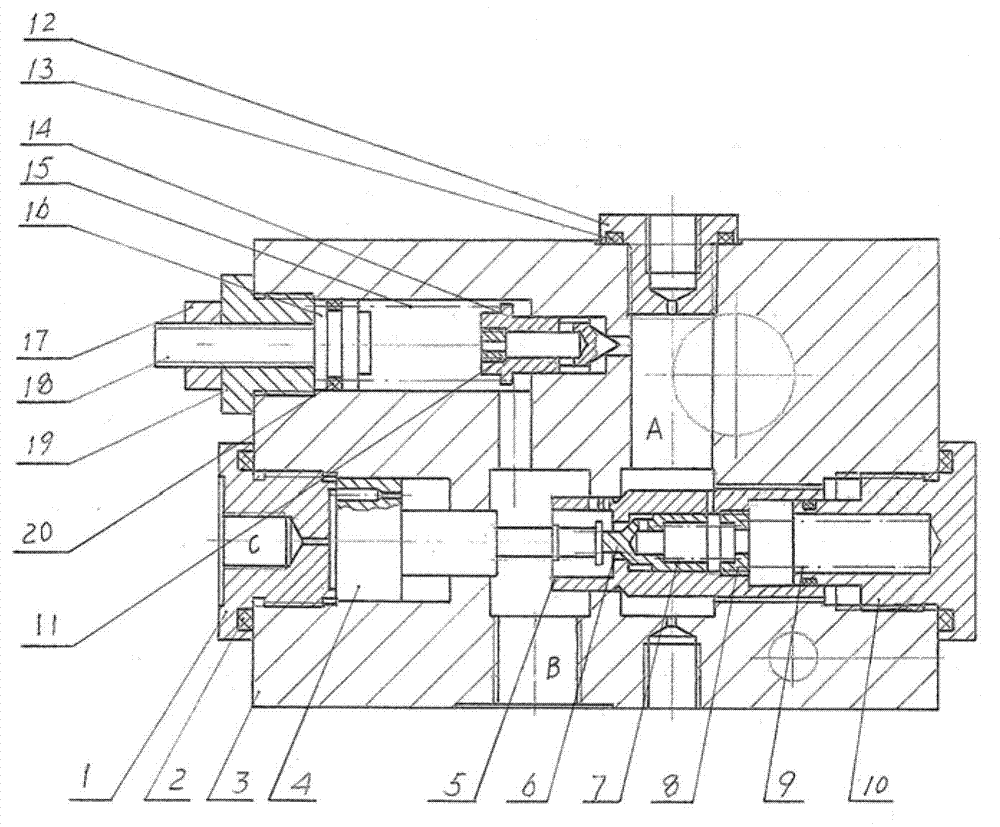

[0007] The specific embodiment of the present invention is: when the hydraulic oil flows from chamber B to chamber A, the one-way valve core 6

[0008] Under the action of the small spring 7, it is in the closed state, the right chamber of the main spool 5 communicates with the A chamber, and the hydraulic oil pushes the main spool 5 together with the one-way spool 6 to compress the main spring 9 to move to the right, and the left end of the main spool 5 The orifice on the small cylindrical sleeve is opened, and the hydraulic oil flows from chamber B to chamber A. When hydraulic oil flows from chamber A to chamber B, chamber C supplies pressure oil, which flows through the orifice on throttle plug 1 to push piston 4 to move to the right, and first pushes check valve core 6 and closes the valve on the right end of main valve core 5. The small hole makes the spring chamber at the right end of the main spool 5 communicate with chamber B, and then pushes the main spool 5 and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com