Activated carbon flowing bed adsorption combination device for adsorbing dust and organic waste gas

A technology of organic waste gas and combined device, which is applied in the direction of combined device, gas treatment, membrane technology, etc., can solve the problems of large occupied area, low land utilization rate, and scattered layout, so as to save occupied area and reduce labor operation The effect of strength, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

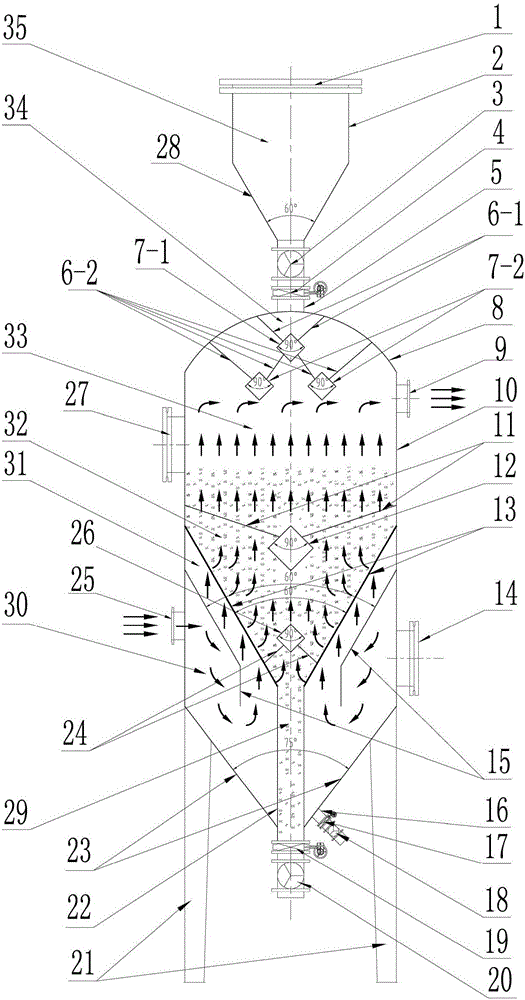

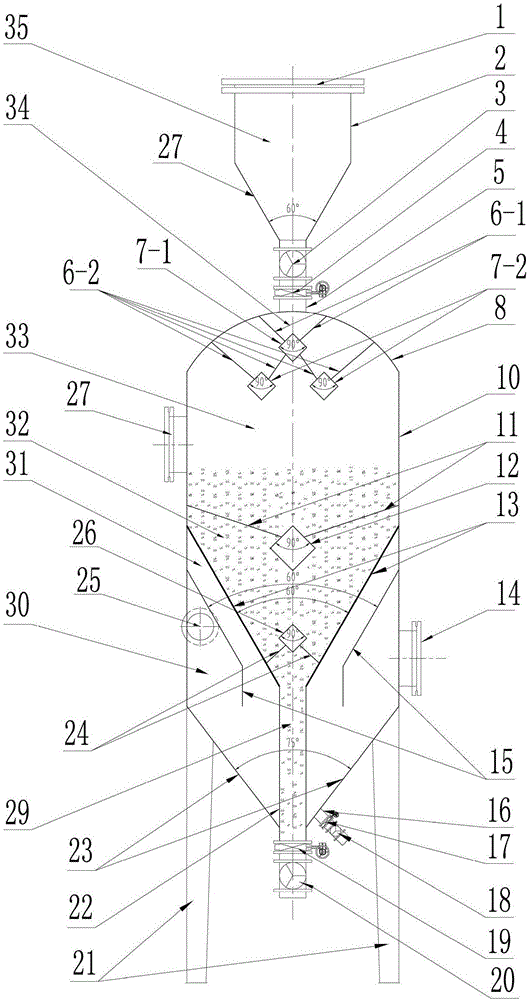

[0037] Such as Figure 1~3 As shown, the technical solution of the present invention provides a schematic diagram of an activated carbon fluidized bed adsorption combined device containing dust and organic waste gas.

[0038] The waste gas produced by an enterprise contains a small amount of dust particles and benzene organic waste gas. If the waste gas is not treated, it will affect the surrounding environment. The waste gas needs to be pretreated by gas-solid separation of waste gas and purified by activated carbon adsorption of benzene organic waste gas.

[0039] The device includes a fresh activated carbon storage area 35, a fresh activated carbon feed uniform distribution area 34, an activated carbon distribution area 32, a waste gas gas-solid swirling separation area 30, a swirling flow uniform gas distribution area 31, a purified gas buffer area 33 and an adsorption saturated The activated carbon feeding area consists of 29 seven units, and the structure is a series mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com